Semi-direct-fired and semi-premixed type boiler turbocharged burner

A turbocharged, semi-premixed technology, used in gas fuel burners, burners, combustion methods, etc., can solve problems such as excessive exhaust gas and harmful impurities, affect combustion quality, and pollute the environment, and achieve good combustion efficiency. The effect of reducing carbon dioxide emissions and large exhaust air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

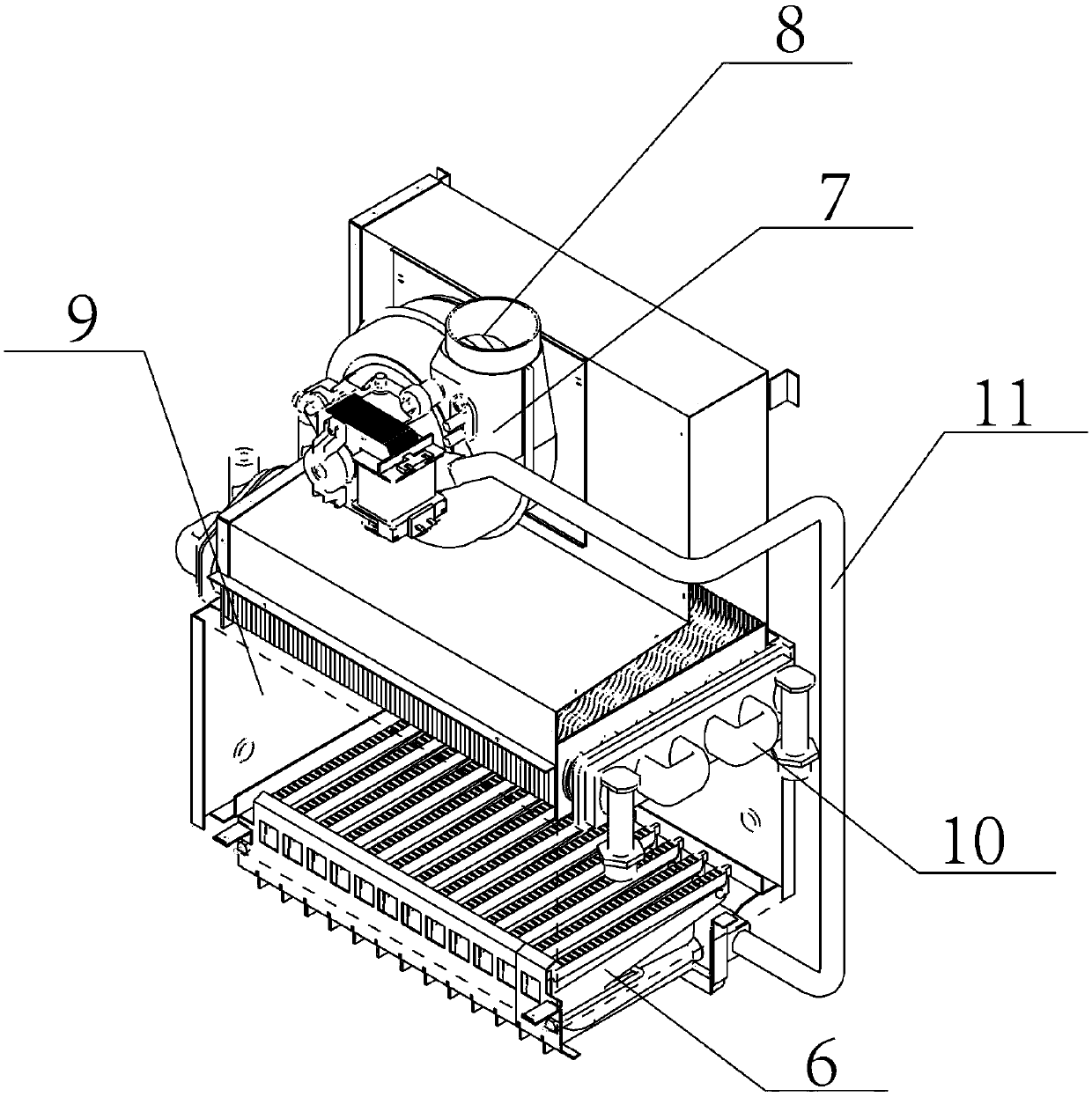

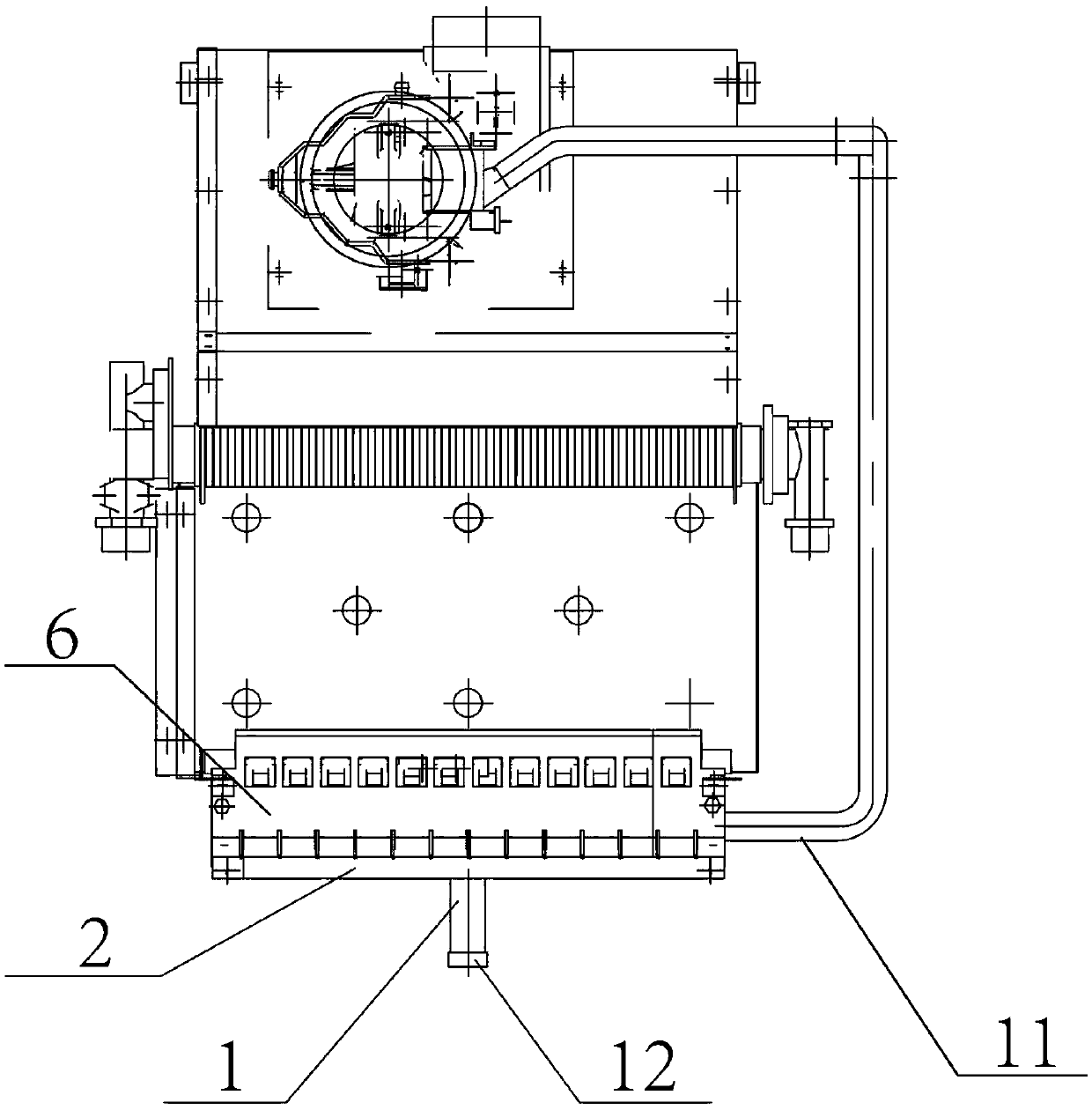

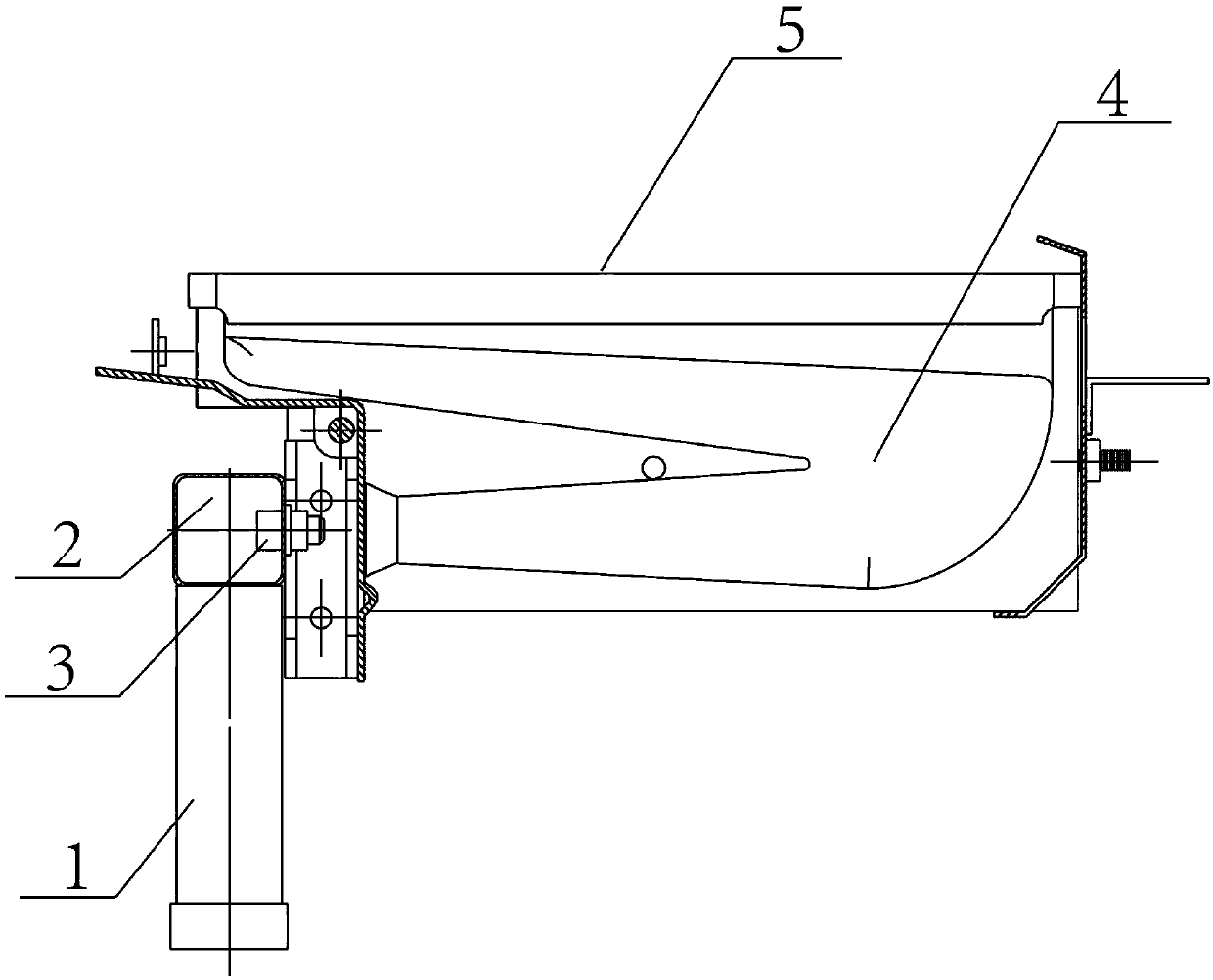

[0025] figure 1 It is a schematic diagram of the three-dimensional structure of the present invention, figure 2 It is a schematic diagram of a side sectional structure of the present invention, image 3 It is a side sectional structural schematic diagram of the burner structure in the present invention, as figure 1 , figure 2 and image 3 A semi-direct-fired semi-premixed boiler turbocharged burner shown includes: gas vertical pipe 1, gas horizontal pipe 2, gas nozzle 3, burner sheet 4, burner nozzle 5, burner 6, Double impeller fan 7, waste gas discharge port 8, combustion chamber 9, heat exchanger 10, press-in air pipeline 11 and gas inlet 12, it is characterized in that: the burner 6 is arranged at the bottom of the combustion chamber 9, so The burner 6 and the combustion chamber 9 are fixedly connected to each other, the gas horizontal pipe 2 is arranged on one side of the burner 6, the gas vertical pipe 1 is arranged at the lower end of the gas horizontal pipe 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com