Intelligent control system of water heater

An intelligent control system and water heater technology, applied in the direction of combustion control, fluid heater, fuel supply adjustment, etc., can solve the problems of inability to do intelligent combustion oxygen supply and water supply and discharge operations, affecting the working environment of operators, and air pollution and other issues to achieve the effect of reducing emissions, improving the working environment, and improving intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

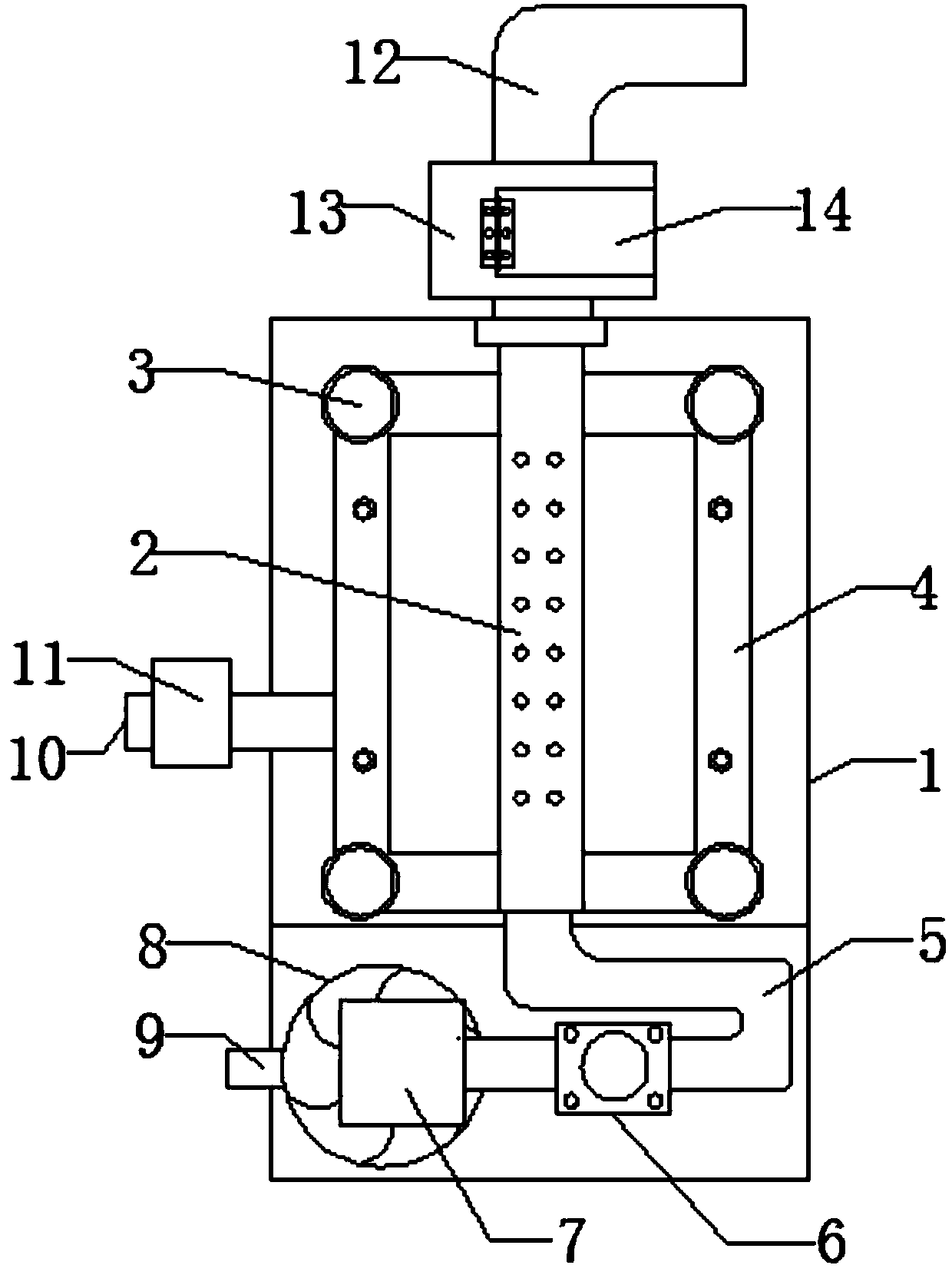

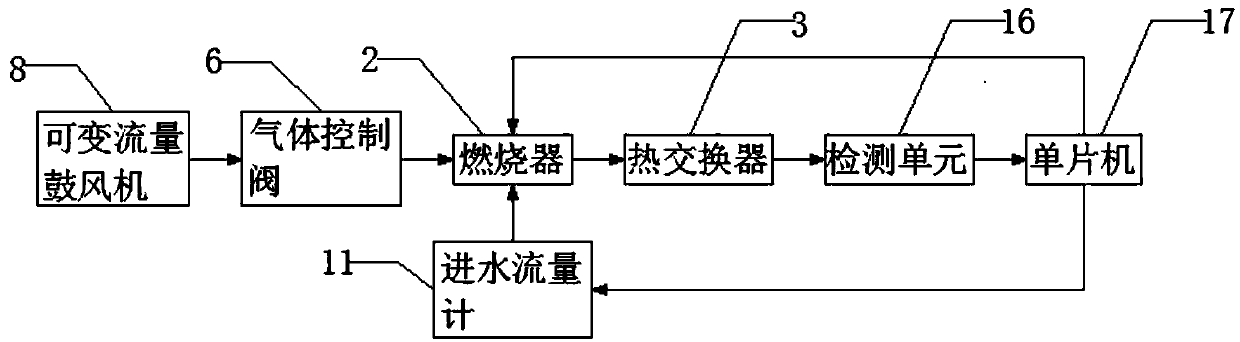

[0021] see Figure 1-3 , this embodiment provides an intelligent control system for a water heater, including a device body 1, a burner 2 is fixedly installed in the middle of the device body 1, a heat exchanger 3 is fixedly installed outside the burner 2, and a gas Supply pipe 5, one end of the gas supply pipe 5 is fixedly installed with a gas control valve 6, the input end of the gas control valve 6 is fixedly connected with a Venturi tube 7 through the gas supply pipe 5, and the other end of the Venturi tube 7 is fixedly installed with a variable flow blower 8 , the input end of the variable flow blower 8 is fixedly connected with the intake pipe 9, the left side of the device body 1 is fixedly connected with the water inlet pipe 10, the water inlet flowmeter 11 is installed on the water inlet pipe 10, and the upper end of the burner 2 is fixedly connected with the waste gas pipeline 12, A purification cartridge 13 is fixedly connected to the waste gas pipeline 12 , a detec...

Embodiment 2

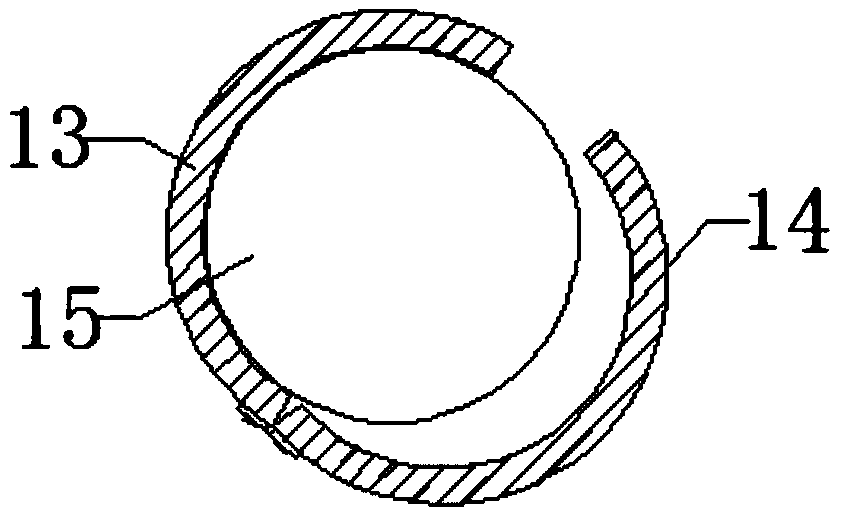

[0024] see Figure 1-3 , on the basis of Example 1, a further improvement has been made: finned tubes 4 are arranged on both sides of the heat exchanger 3, which can increase the outer surface area of the heat exchange tubes, thereby achieving the purpose of improving heat exchange efficiency, and the side of the purification cylinder 13 passes through The hinge is rotatably connected with a sealed door 14, and the sealed door 14 is fixedly connected with a filter sheet 15. The filter sheet 15 can be replaced regularly through the sealed door 14, which is convenient for use. The filter sheet 15 is a filter material purification sheet, which is harmful to the filter The gas effect is better. The exhaust gas pipeline 12 is made of high molecular polymer material, which has good heat resistance and corrosion resistance. The input signal of the water inlet flow meter 11 is the flow rate signal from the water inlet pipe 10. The structure is reasonable and easy to detect. , the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com