A local adaptive controllable wettability coupling microstructure enhanced boiling heat transfer method

A locally adaptive and enhanced boiling technology, applied in the field of enhanced heat transfer, which can solve problems such as the increase of vaporization cores and the growth of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

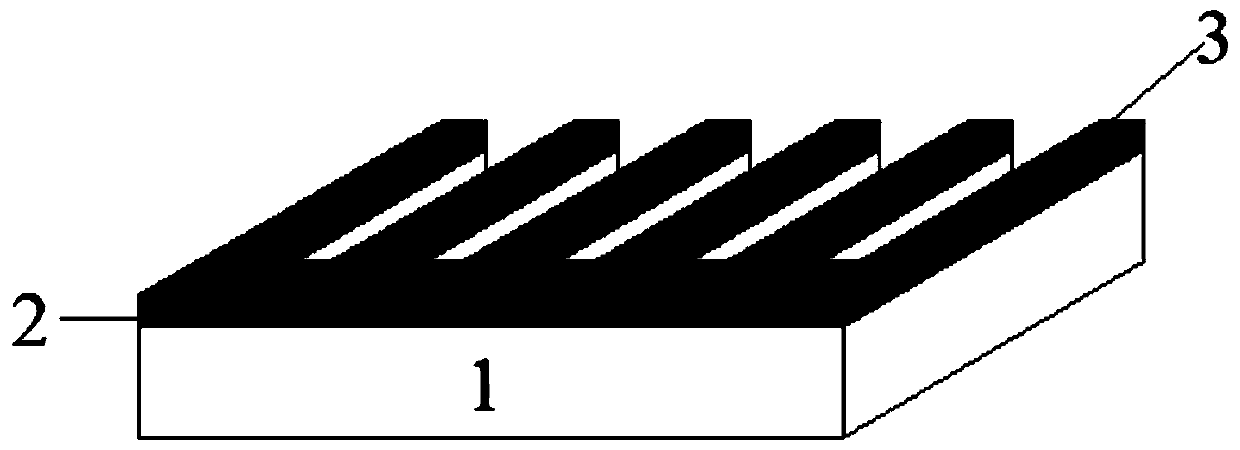

[0035] Single crystal silicon is selected as the heat exchange substrate material, flat, with a size of 30mm×10mm×2mm; the surface is designed with a microcolumn array, the size of the microcolumns is 150μm×150μm×150μm, and the spacing is 200μm; the surface of the heat exchange substrate is metal oxide with excellent thermal conductivity Physical insulating layer with a thickness of 100nm.

[0036] A conductive gold film with a thickness of 100nm is provided as an electrode film on the top of the microcolumn, and the conductive gold film with a thickness of 100nm is used as an electrode lead to connect and lead out the electrode films distributed on the top of the microcolumn. Both have a metal oxide insulating layer with a thickness of 100nm and excellent thermal conductivity.

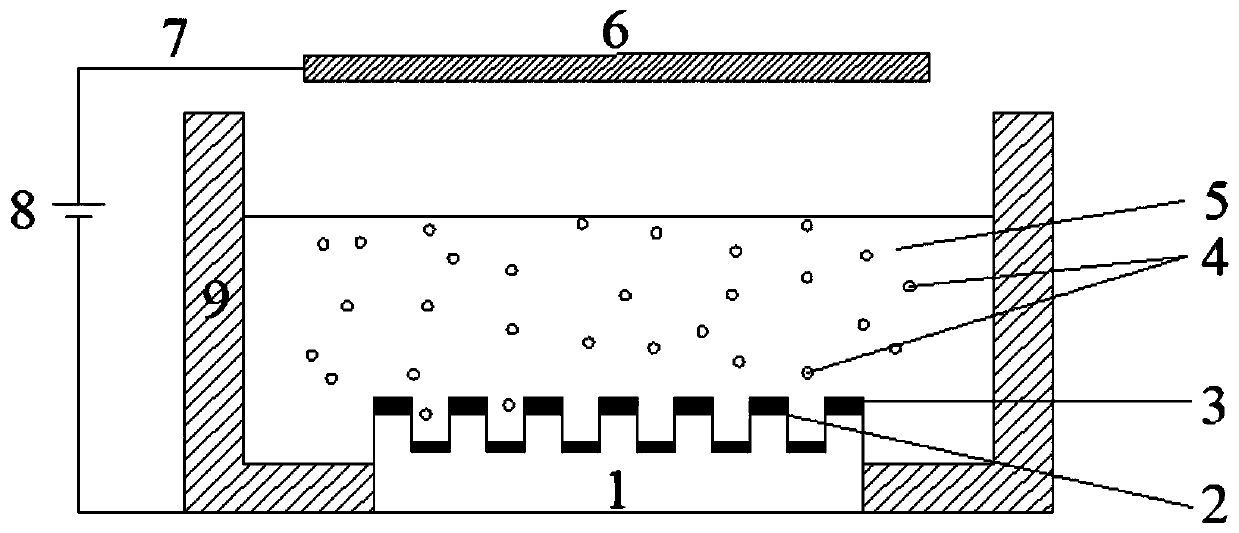

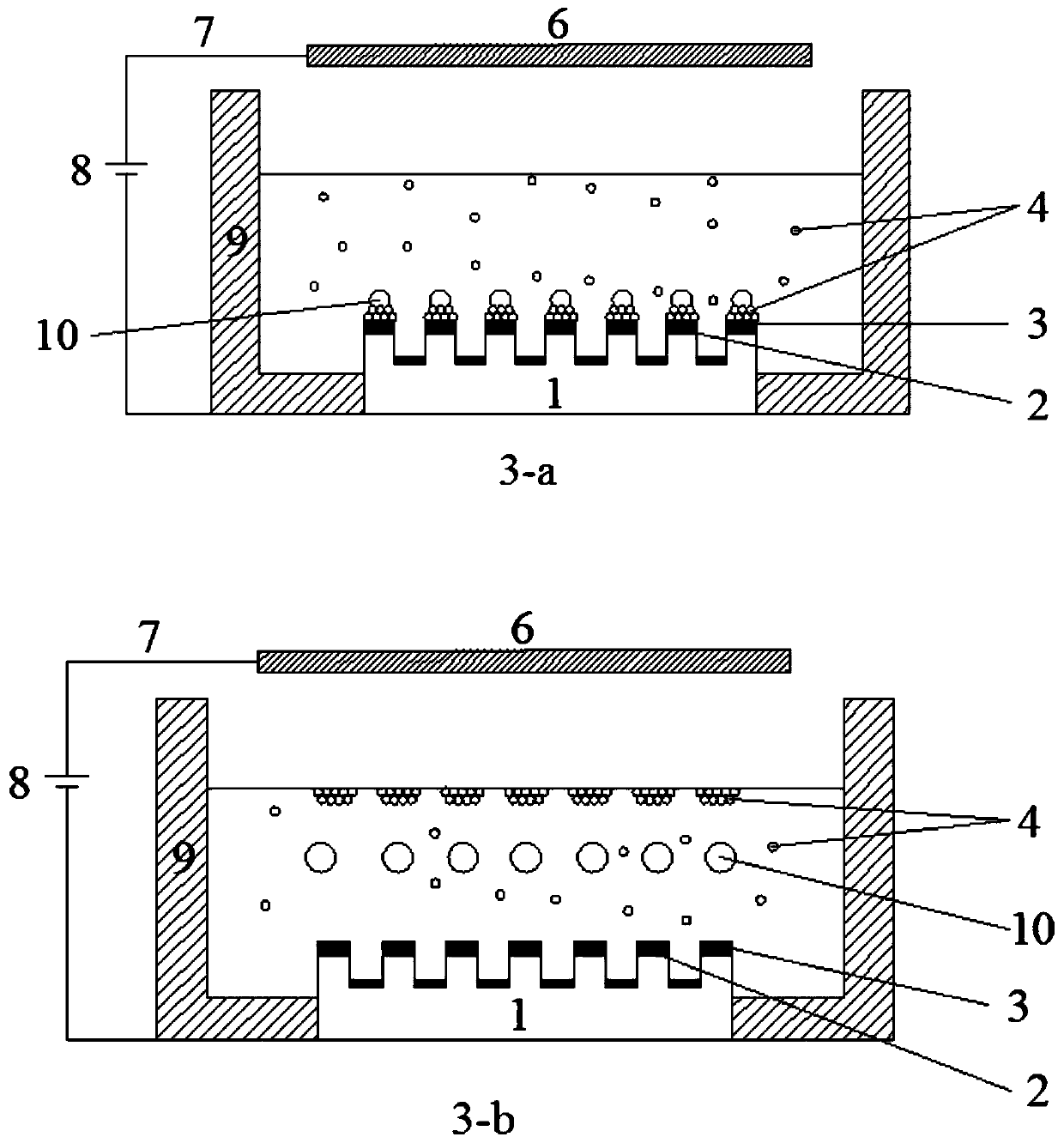

[0037] Metal copper nanoparticles with a particle size of 30nm are selected, charged with anion and cation surfactants and hydrophobic treatment, and configured into a nanofluid as a heat-exchange worki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com