Echo signal separation method for ultrasonic flaw detection

A technology of ultrasonic echo and echo signal, applied in the field of ultrasonic flaw detection, can solve the problems of sparse representation instability, unreliability, no physical meaning, poor algorithm performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

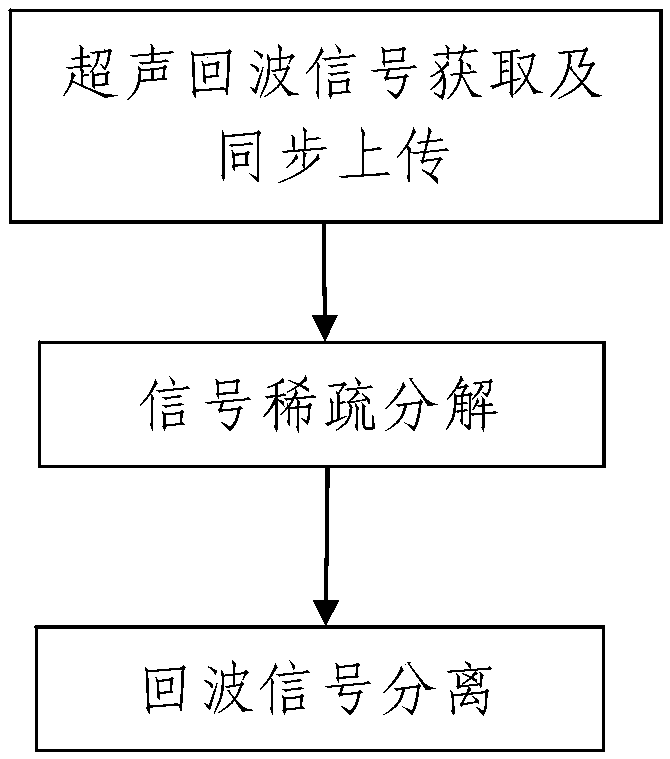

[0124] Such as figure 1 A method for separating echo signals for ultrasonic flaw detection is shown, comprising the following steps:

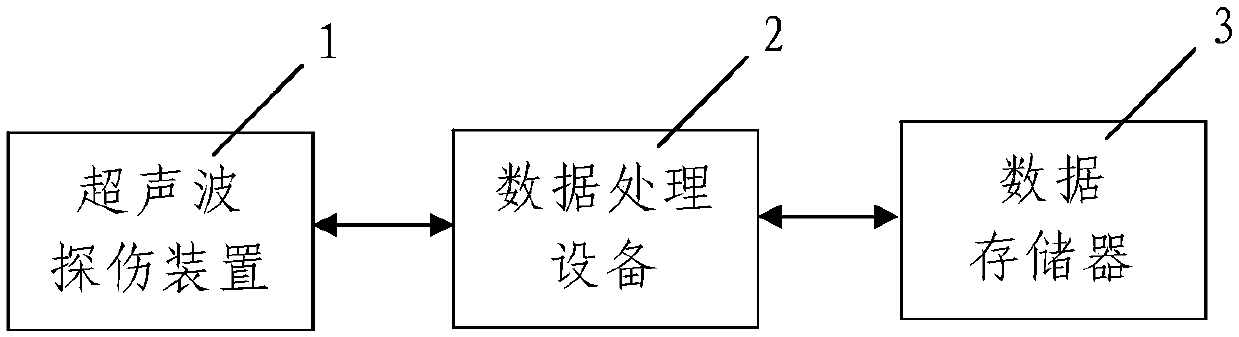

[0125] Step 1. Ultrasonic echo signal acquisition and synchronous upload: use the ultrasonic flaw detection device 1 to perform ultrasonic detection on the object under test, obtain the ultrasonic echo signal F(t) of the object under test, and transfer the obtained ultrasonic echo signal F(t) t) synchronously transmitted to the data processing device 2;

[0126] Among them, F(t)=[f(t 1 ), f(t 2 ),...,f(t N' )] T , t represents the time parameter, t i is the i-th sampling moment of the ultrasonic flaw detection device 1, f(t i ) is the signal value sampled at the ith sampling time of the ultrasonic flaw detection device 1, i is a positive integer and i=1, 2, 3, ..., N', N' is a positive integer and it is the ultrasonic echo signal F( t) signal length;

[0127] in,[] TRepresents the transpose of the matrix; [f(t 1 ), f(t 2 ),...,f(t N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com