Copper-filled groove structure and method of manufacturing the same

A manufacturing method, a technology of copper filling, applied in the manufacture of groove structures, the field of copper-filled groove structures, can solve the problem that the copper main layer cannot directly contact the metal layer at the bottom, increase the parasitic resistance of through holes, and increase the complexity of the process and other issues to achieve the effect of improving EM performance, reducing parasitic resistance, and improving EM performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

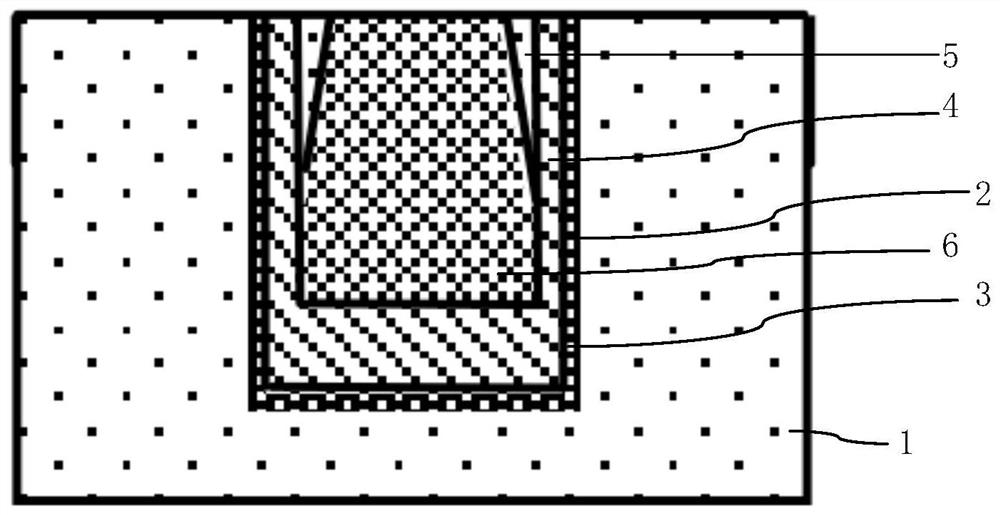

[0038] Such as figure 1 As shown, it is a device structure diagram of a copper-filled groove structure according to an embodiment of the present invention. The copper-filled groove structure according to an embodiment of the present invention includes:

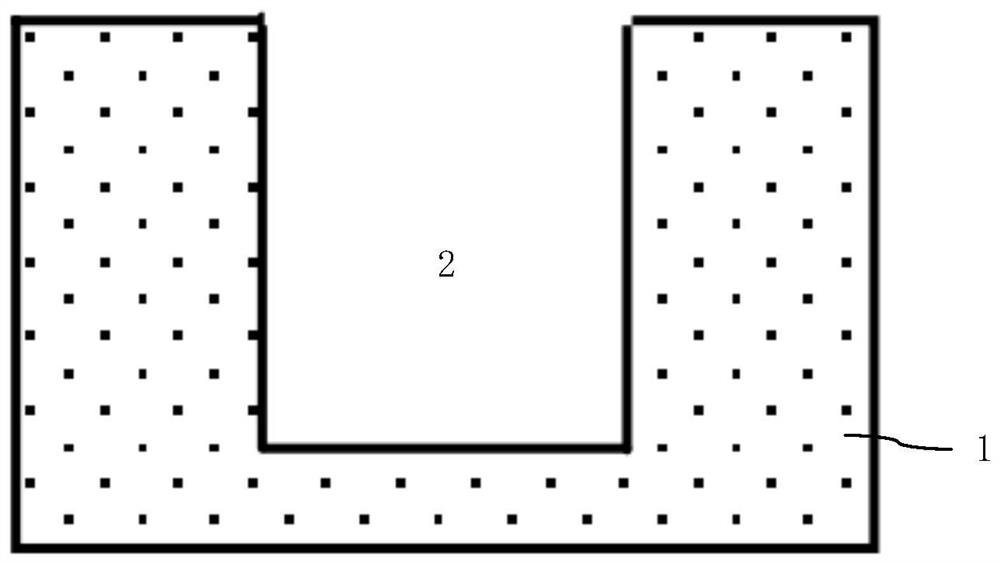

[0039] The groove 2 is formed in the first dielectric layer 1 .

[0040] In the embodiment of the present invention, the first dielectric layer 1 is an interlayer film, and the groove structure is a through hole connecting the upper and lower metal layers. Since the through hole is used to connect the upper and lower metal layers, actually the groove 2 will pass through the first dielectric layer 1 and expose the metal layer formed at the bottom of the first dielectric layer 1 .

[0041] The material of the first dielectric layer 1 is an oxide layer.

[0042] A barrier layer 3 is formed on the bottom surface and sides of the groove 2 .

[0043] Usually, the material of the barrier layer 3 is TaN.

[0044] A first seed laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com