Gate tube material, gate tube device and preparation method thereof

A technology of gating tubes and devices, which is applied in the field of Wiener Electronics, can solve the problems of insufficient on-state loadable current, high threshold voltage of gating tubes, high off-state leakage current, etc., to reduce power consumption, reduce on-voltage, The effect of increasing the switching ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a method for preparing the above gating tube device unit, comprising the following steps:

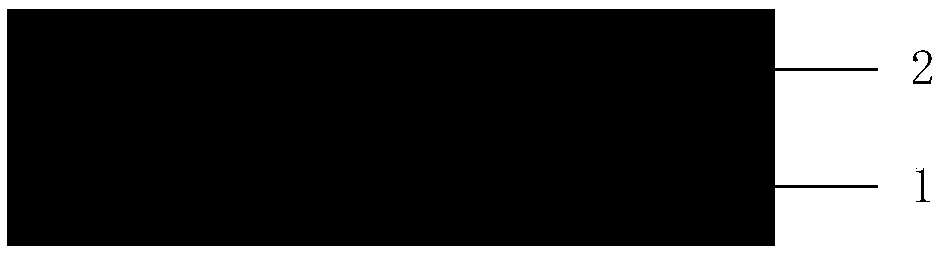

[0045] (1) preparing the first metal electrode layer on the substrate;

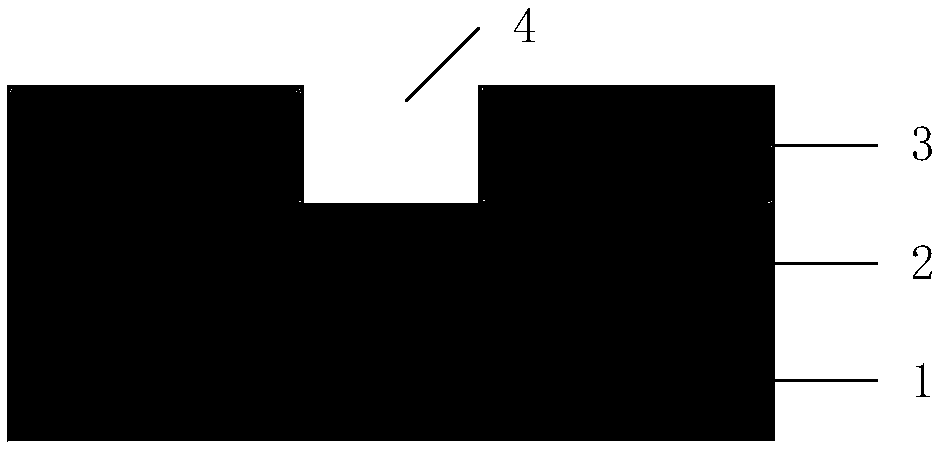

[0046] (2) An insulating layer is prepared on the first metal electrode layer, and the insulating layer is patterned to obtain a hole structure, and part of the first metal electrode layer at the bottom is exposed through the hole structure; Photolithography or electron beam lithography (EBL) is used to form patterns, and then conductance coupled plasma etching (ICP) is used to obtain patterns of different shapes.

[0047] (3) preparing a gating layer on the exposed first metal electrode layer, filling the hole structure, and the material used in the gating layer is the gating tube material as described above;

[0048] (4) A second metal electrode layer is prepared on the insulating layer filled with the hole structure, and the first metal electrode layer and the second metal ...

Embodiment 1

[0052] This implementation example provides a gating tube material, which is characterized in that: the general chemical formula of the gating tube material can be expressed as Ge x Te y A 100-x-y (where A refers to one of the elements C, B, Si, Al, Sb, Bi), x, y are the atomic percentage of the element and 10≤x<60, 40<y<90, 0<100-x-y≤ 25.

[0053] Preferably, in the Ge x Te y A 100-x-y (where A refers to one of the elements C, B, Si, Al, Sb, Bi), the element C is selected to form Ge x Te y C 100-x-y , and 10≤x<60, 40

[0054] More preferably, in the Ge x Te y A 100-x-y (where A refers to one of the elements C, B, Si, Al, Sb, Bi), the element C is selected to form Ge x Te y C 100-x-y , and 20≤x≤45, 55

[0055] More specifically, the material thickness of the gate tube is 1-200 nm. Preferably, in this implementation case, the material thickness of the gate tube is 120nm; of course, in other implementation cases, the materi...

Embodiment 2

[0060] This embodiment also provides a method for manufacturing the gating tube material as described in Embodiment 1, according to the schematic formula Ge of the general chemical formula x Te y A 100-x-y (Among them, A refers to one of the elements C, B, Si, Al, Sb, Bi). The gate tube material is prepared by enhanced chemical vapor deposition, low pressure chemical vapor deposition, metal compound vapor deposition, molecular beam epitaxy, atomic vapor deposition, and atomic layer deposition.

[0061] Preferably, in this embodiment, the selected element C constitutes Ge x Te y C 100-x-y thin films, and prepared Ge by magnetron co-sputtering x Te y C 100-x-y thin film; more preferably, the Ge x Te y C 100-x-y Thin film is Ge 20 Te 65 C 15 film.

[0062] Specifically: use Ge 25 Te 75 Alloy target, Ge 50 Te 50 Co-sputtering of alloy target and C target to deposit a certain thickness of Ge 20 Te 65 C 15 Thin film, the process parameters are: pumping to the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com