Antifog laminate

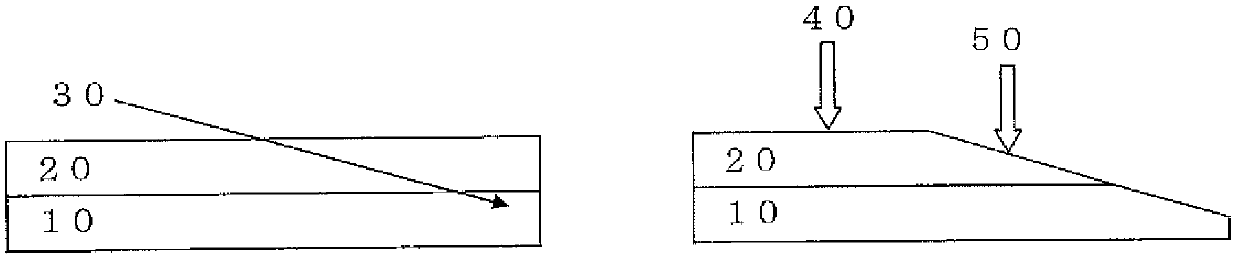

一种层叠体、亲水层的技术,应用在涂层、分层产品、合成树脂层状产品等方向,能够解决难初始防雾性、视觉辨认性下降、防雾性下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0457] For Example 1 and Comparative Example 10, the water contact angle after water washing was also measured.

[0458] The term "after washing with water" here refers to a sample in which the surface of the sample was washed with running water for 30 seconds, and then dried by air blowing.

[0459] In the present invention, the evaluation of the structure of the copolymers (i), (ii) and (iii) was performed as follows.

[0460]

[0461] use 13 C-NMR analysis has a unit (1) containing a sulfonic acid group, a unit (2) having an epoxy group, and a unit ratio (1) / unit (3) having a trialkoxysilyl group (2) / (3). The measurement conditions are described below.

[0462] (measurement conditions)

[0463] *Device: ECX-400P (JEOL)

[0464] *Measurement core: 13 C

[0465] *Measurement mode: single pulse proton broadband decoupling

[0466] * Pulse width: 45° (5.0 microseconds)

[0467] *Points: 64K

[0468] *Observation range: 31407Hz

[0469] * Number of scans: 20000 time...

Synthetic example 1

[0532] [Synthesis Example 1]

[0533] 936.9 g of methanol degassed under reduced pressure was charged into the reaction flask, and 38.3 g (0.580 mol) of KOH pellets with a purity of 85 wt % were gradually added thereto and completely dissolved while stirring. Next, 124.0 g (0.585 mol) of acrylamide-tert-butylsulfonic acid (hereinafter referred to as ATBS) was charged in portions, and neutralized (PH=7.6) to produce acrylamide-tert-butylsulfonic acid A neutralized mixture of acid potassium salt (hereinafter referred to as ATBS-K.).

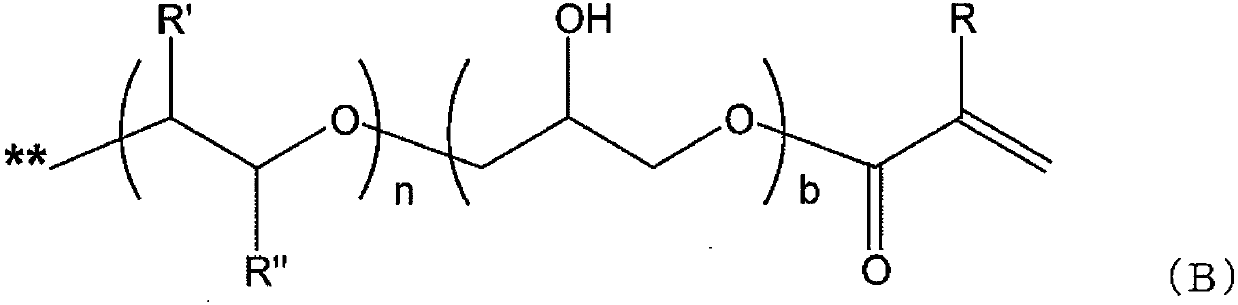

[0534] Next, 10.3 g (0.0725 mol) of glycidyl methacrylate (hereinafter, abbreviated as GMA), methacryloxypropyltriethoxysilane (hereinafter, abbreviated as KBE-503.) 21.1 g (0.0725 mol) and 2.0 g of methanol, and a mixture of 0.63 g of tert-butyl peroxy-2-ethylhexanoate (hereinafter, abbreviated as perbutyl-O) as a polymerization initiator and 6.3 g of methanol . They were loaded in portions (one-third each time) through 2 hours respectively in...

Embodiment 2

[0561]

[0562] Add 30 g of 1-methoxy-2-propanol, 2-hydroxy-2- 2.1 g of methylpropiophenone (manufactured by Ciba Japan K.K., trade name: DAROCURE1173) was stirred and mixed to prepare coating composition B2.

[0563]

[0564] In the same manner as in Example 1, a sample obtained by coating and curing the above-mentioned urethane-based primer on blue plate glass was made, and the coating composition was coated with a spin coater at 500 rpm for 60 seconds. A laminate was formed in the same manner as in Example 1 except that B2 was applied on the surface of the primer layer to form a water-absorbing layer with a thickness of 12 μm.

[0565] The evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com