Method for treating sausage casing wastewater

A treatment method and casing technology are applied in the field of casing wastewater treatment, which can solve the problems of high wastewater treatment cost, impact on enterprise economic benefits and high energy consumption, and achieve the effect of full energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

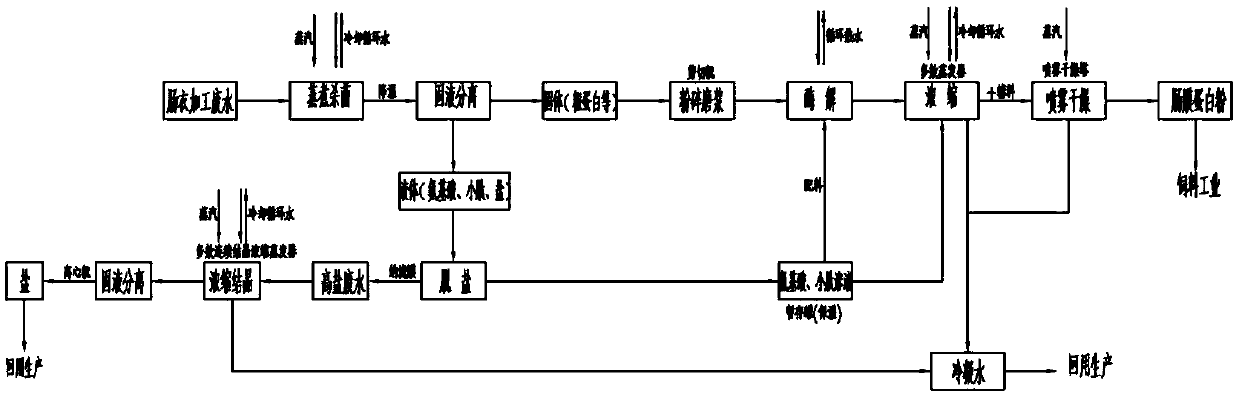

Method used

Image

Examples

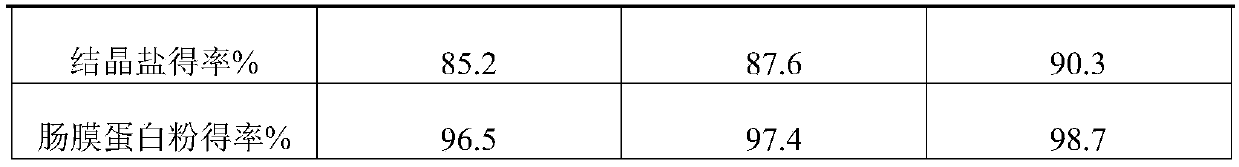

Embodiment 1

[0052] A treatment method for casing waste water, comprising the steps of:

[0053] 1) Sterilization: sterilize the artificial collagen casing wastewater to be treated at 115°C for 30 minutes;

[0054] 2) Solid-liquid separation: Cool the sterilized material to 60°C, and send it to a centrifuge at a centrifugal speed of 1500r / min for 10 minutes to obtain the filtrate and protein-rich solids;

[0055] 3) Desalination: pass the filtrate through a nanofiltration device to obtain high-salt wastewater, amino acid, and peptide solutions; high-salt wastewater undergoes multi-effect continuous crystallization to obtain crystallized salt and casing reuse water;

[0056] 4) Pulverizing and refining

[0057] Pulverizing and refining the protein-rich solids in step 2) to obtain a slurry;

[0058] 5) Enzymolysis

[0059] Mix the slurry of step 3) amino acid, peptide solution and step 4) into the enzymolysis tank, the mass ratio of amino acid, peptide solution and slurry is 1:3, add 1% c...

Embodiment 2

[0065] A treatment method for casing waste water, comprising the steps of:

[0066] 1) Sterilization: sterilize the artificial collagen casing wastewater to be treated at high temperature, the sterilization temperature is 120°C, and the sterilization time is 30 minutes;

[0067] 2) Solid-liquid separation: Cool the sterilized material to 65°C and send it to a centrifuge for centrifugation at a speed of 1500r / min for 20 minutes to obtain filtrate and protein-rich solids;

[0068] 3) Desalting: passing the filtrate through a nanofiltration device to obtain high-salt wastewater, amino acid and peptide solutions; the high-salt wastewater is continuously crystallized through multiple effects to obtain crystalline salt and casing reuse water;

[0069] 4) Pulverizing and refining

[0070] Pulverizing and refining the protein-rich solids in step 2) to obtain a slurry;

[0071] 5) Enzymolysis

[0072] Mix step 3) amino acid, peptide solution and step 4) slurry into the enzymolysis t...

Embodiment 3

[0078] A treatment method for casing waste water, comprising the steps of:

[0079] 1) Sterilization: sterilize the artificial collagen casing wastewater to be treated at high temperature at 125°C for 30 minutes;

[0080] 2) Solid-liquid separation: Cool the sterilized material at a cooling temperature of 70°C and send it to a centrifuge for centrifugation at a speed of 1500r / min for 30 minutes to obtain filtrate and protein-rich solids;

[0081] 3) Desalination: pass the filtrate through a nanofiltration device to obtain high-salt wastewater, amino acid, and peptide solutions; high-salt wastewater undergoes multi-effect continuous crystallization to obtain crystallized salt and casing reuse water;

[0082] 4) Pulverizing and refining

[0083] Pulverizing and refining the protein-rich solids in step 2) to obtain a slurry;

[0084] 5) Enzymolysis

[0085] Mix the slurry of step 3) amino acid, peptide solution and step 4) into the enzymolysis tank, the mass ratio of amino aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com