Radix ophiopogon root extract and preparation method and application thereof

A technology of extract and fibrous root, which is applied in the field of Ophiopogon japonicus fibrous root extract and its preparation, and achieves the effects of reducing energy consumption, saving cost and shortening extraction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

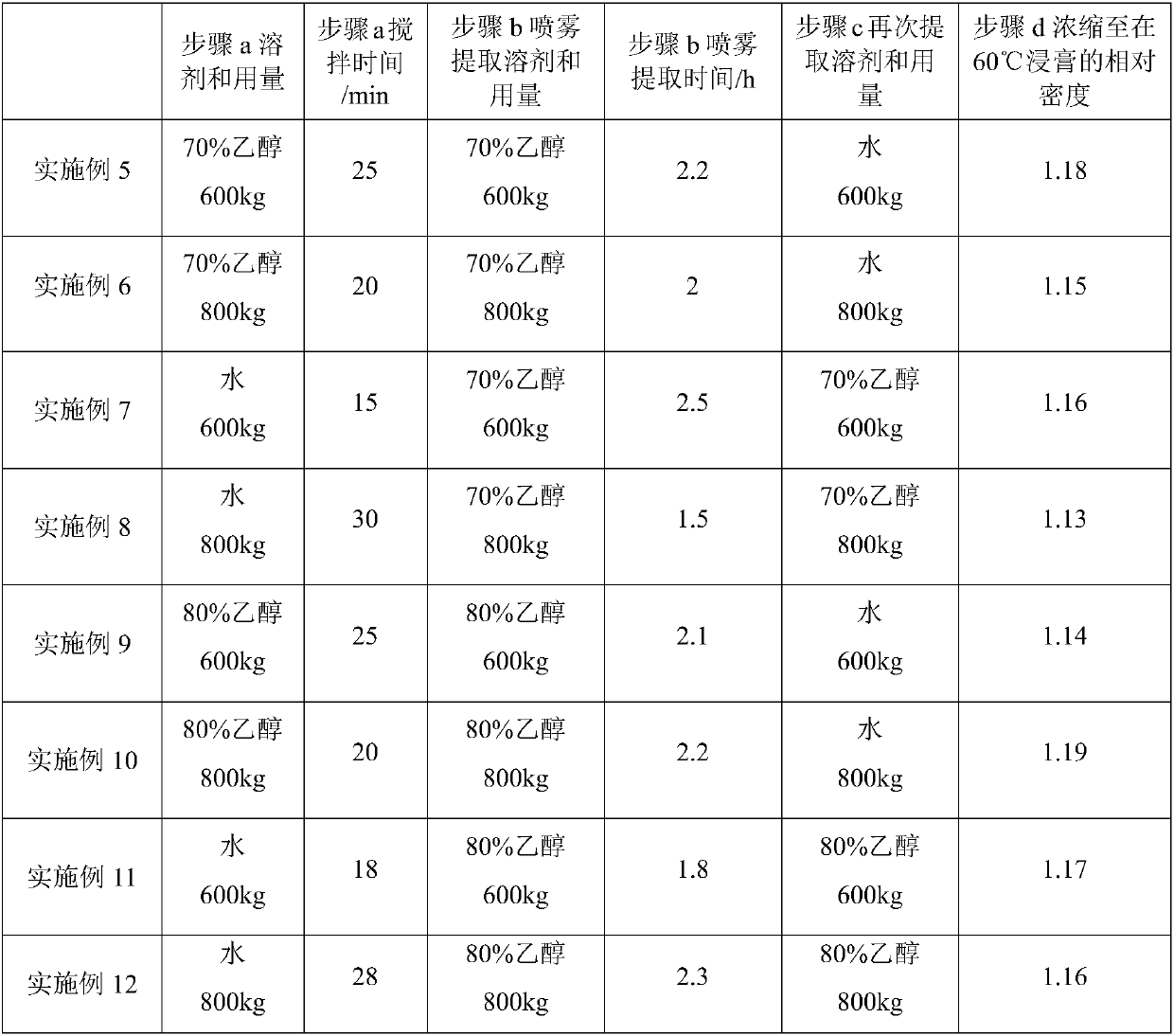

Examples

preparation example Construction

[0035] The preparation method of Ophiopogon japonicus fibrous root extract provided by the invention comprises the following steps:

[0036] A, get the fibrous root of Ophiopogon japonicus, wash, dry, pulverize into fine powder, add the ethanol or water of 60%~80% mass concentration of 6 to 8 times the weight of the Radix Radix Radix et Rhizoma, and stir for 10 to 30 minutes, filter through a 60-mesh sieve to obtain Ophiopogon japonicus fibrous root slurry;

[0037] Among them, in order to increase the contact area between the fibrous root of Ophiopogon japonicus and the extraction solvent, the fibrous root of Ophiopogon japonicus was pulverized into a fine powder according to the 2015 edition of the Chinese Pharmacopoeia. In the steps of the present invention, ethanol or water is used as the extraction solvent, no harmful organic solvent is involved, the production process is pollution-free, the cost is low, and it is suitable for preparing functional food. The preferred mas...

Embodiment 1

[0049] A, get Ophiopogon japonicus fibrous root 100kg, clean, dry, pulverize to be fine powder, add the ethanol of 600kg 60% mass concentration and stir 20 minutes, obtain Ophiopogon japonicus fibrous root slurry by 60 mesh sieve filtration.

[0050] b. Add 600kg of 60% ethanol in the extraction tank, start the plunger pump, and control the pressure at 1.8-2.0Mpa, so that the Ophiopogon japonicus fibrous root slurry is dispersed into a mist through the nozzle and sprayed into the extraction tank under the pressure of the plunger pump. Inside, after 2 hours of extraction, an extract is obtained, and the extract is first filtered through a liquid filter press with a 200-mesh coarse filter, and then passed through a connecting pipeline and then passed through a 800-mesh fine filtration to obtain a filtrate 1 and a filter residue 1.

[0051] c. Add 600kg of water to filter residue 1, and operate according to steps a and b to obtain filtrate 2 and filter residue 2; filter residue 2 ...

Embodiment 2

[0054] A, get Ophiopogon japonicus fibrous root 100kg, clean, dry, pulverize to be fine powder, add the ethanol of 800kg 60% mass concentration and stir 20 minutes, obtain Ophiopogon japonicus fibrous root slurry by 60 mesh sieve filtration.

[0055] b. Add 800kg of 60% ethanol in the extraction tank, start the plunger pump, and control the pressure at 1.8-2.0Mpa, so that the Ophiopogon japonicus fibrous root slurry is dispersed into a mist through the nozzle and sprayed into the extraction tank under the pressure of the plunger pump. Inside, after 2 hours of extraction, an extract is obtained, and the extract is first filtered through a liquid filter press with a 200-mesh coarse filter, and then passed through a connecting pipeline and then passed through a 800-mesh fine filtration to obtain a filtrate 1 and a filter residue 1.

[0056] c. Add 600kg of water to filter residue 1, and operate according to steps a and b to obtain filtrate 2 and filter residue 2; filter residue 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com