Purification and recovery method of coking waste gas

A recovery method and waste gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of substandard emissions and high operating costs, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

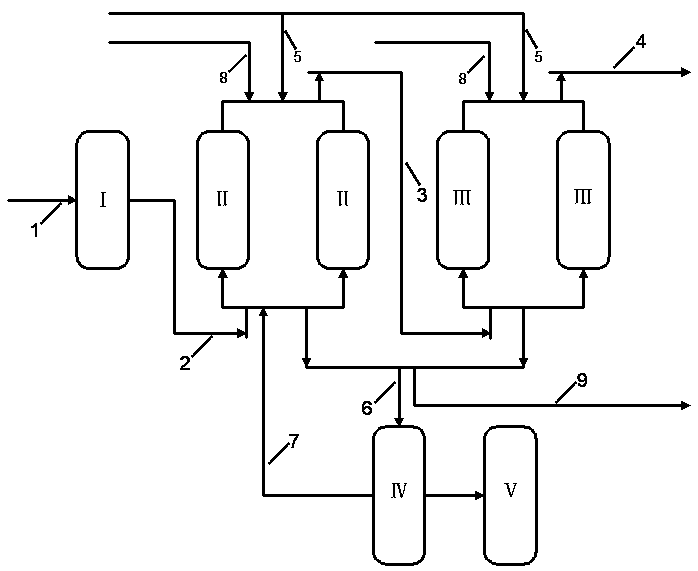

[0033] a. Coking exhaust gas enters the buffer tank, and after pre-filtering dust, viscous organic matter and moisture, stream I is formed;

[0034] b. Stream I enters adsorption tower A, which is filled with molecular sieve adsorbents to absorb hydrogen sulfide, ammonia, hydrogen cyanide and other acid gases, tar, naphthalene, benzene series, polycyclic and heterocyclic aromatic hydrocarbons and organic sulfur. Form logistics Ⅱ;

[0035] c. Logistics II is discharged through the chimney;

[0036] d. When the adsorption tower A is saturated, switch to the standby adsorption tower B for adsorption, and the adsorption tower A enters the regeneration process, and the desorbed gas is regenerated to form stream III;

[0037] e. Stream Ⅲ enters the cooler for cooling, and the cooled liquid is discharged into the liquid storage tank to collect and recover aromatics; the cooled gas forms stream Ⅳ, returns to adsorption tower B, and re-adsorbs and purifies;

[0038] f. Dry the regene...

Embodiment 2

[0044] a. Coking exhaust gas enters the buffer tank, coarsely filters dust, viscous organic matter and moisture to form stream Ⅰ;

[0045] b. Stream I enters an adsorption tower in the adsorption device combination a, and the adsorption device combination a contains at least 2 adsorption towers,

[0046] Each adsorption tower is filled with molecular sieve adsorbent A to absorb hydrogen sulfide, ammonia, hydrogen cyanide and other acid gases to form stream II;

[0047] c. Stream II enters the adsorption device combination b, which contains at least 2 adsorption towers, and each adsorption tower

[0048] Molecular sieve adsorbent B is filled in the middle to adsorb tar, naphthalene, benzene series, polycyclic and heterocyclic aromatic hydrocarbons and organic sulfur to form stream III;

[0049] d. Logistics Ⅲ up-to-standard discharge;

[0050] e. When the adsorption towers in the adsorption device combinations a and b are saturated, each switch to another adsorption tower in ...

Embodiment 3

[0060] Coking exhaust gas enters the buffer tank, coarsely filters dust, viscous organic matter and moisture, and forms stream Ⅰ;

[0061] Stream I enters an adsorption tower in the adsorption device combination a, and the adsorption device combination a contains at least 2 adsorption towers,

[0062] Each adsorption tower is filled with molecular sieve adsorbent A to absorb hydrogen sulfide, ammonia, hydrogen cyanide and other acid gases to form stream II;

[0063] Stream II enters the adsorption device combination b, which contains at least 2 adsorption towers, and each adsorption tower

[0064] Molecular sieve adsorbent B is filled in the middle to adsorb tar, naphthalene, benzene series, polycyclic and heterocyclic aromatic hydrocarbons and organic sulfur to form stream III;

[0065] Logistics Ⅲ up-to-standard discharge;

[0066] When the adsorption towers in the adsorption device combinations a and b are saturated, each switch to another adsorption tower in the group fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com