Raw material processing equipment for cattle feed production

A processing equipment and cattle feed technology, applied in feed, application, grain processing, etc., can solve the problem of large space utilization, achieve the effect of reducing space use, improving screening effect, and better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

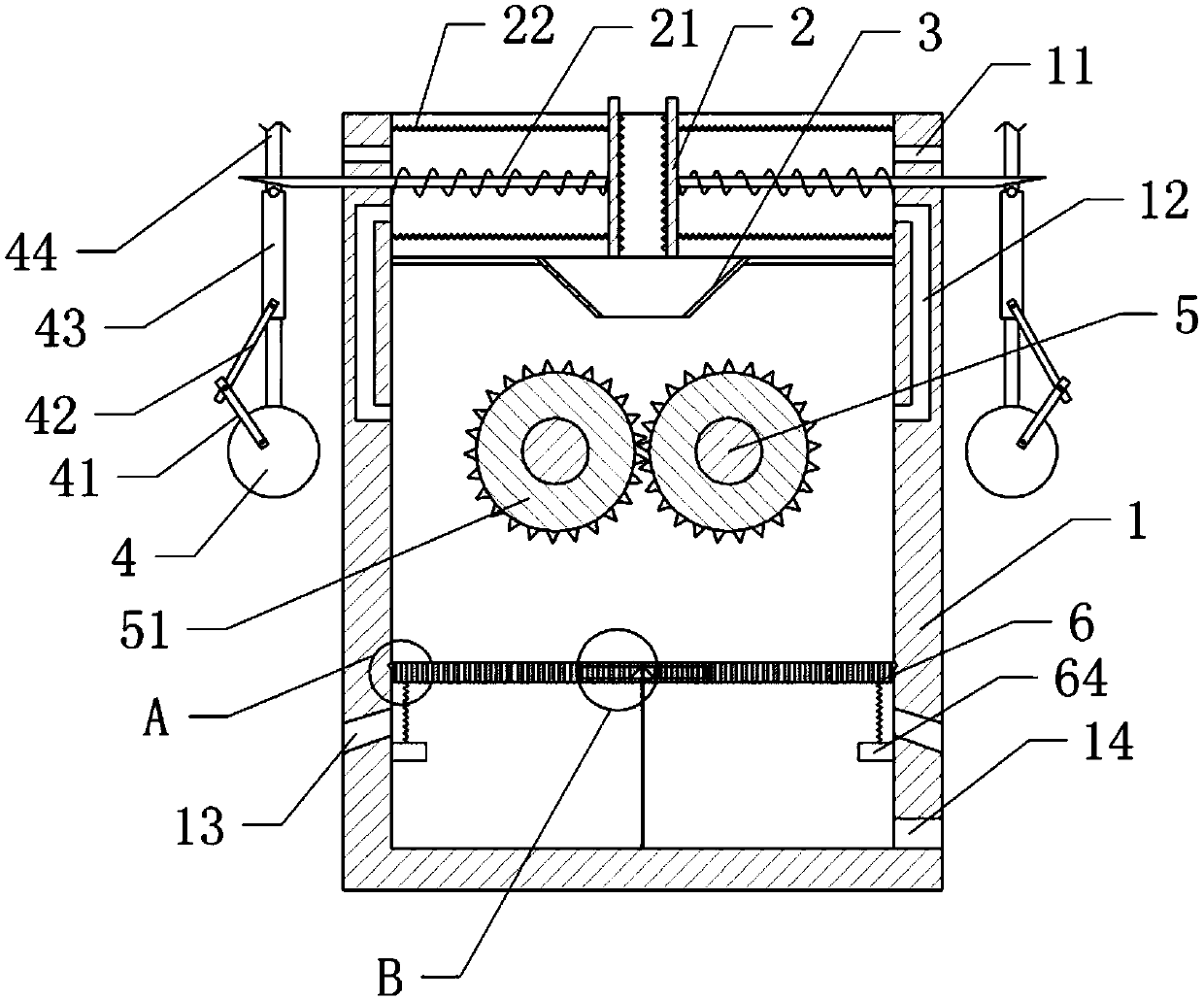

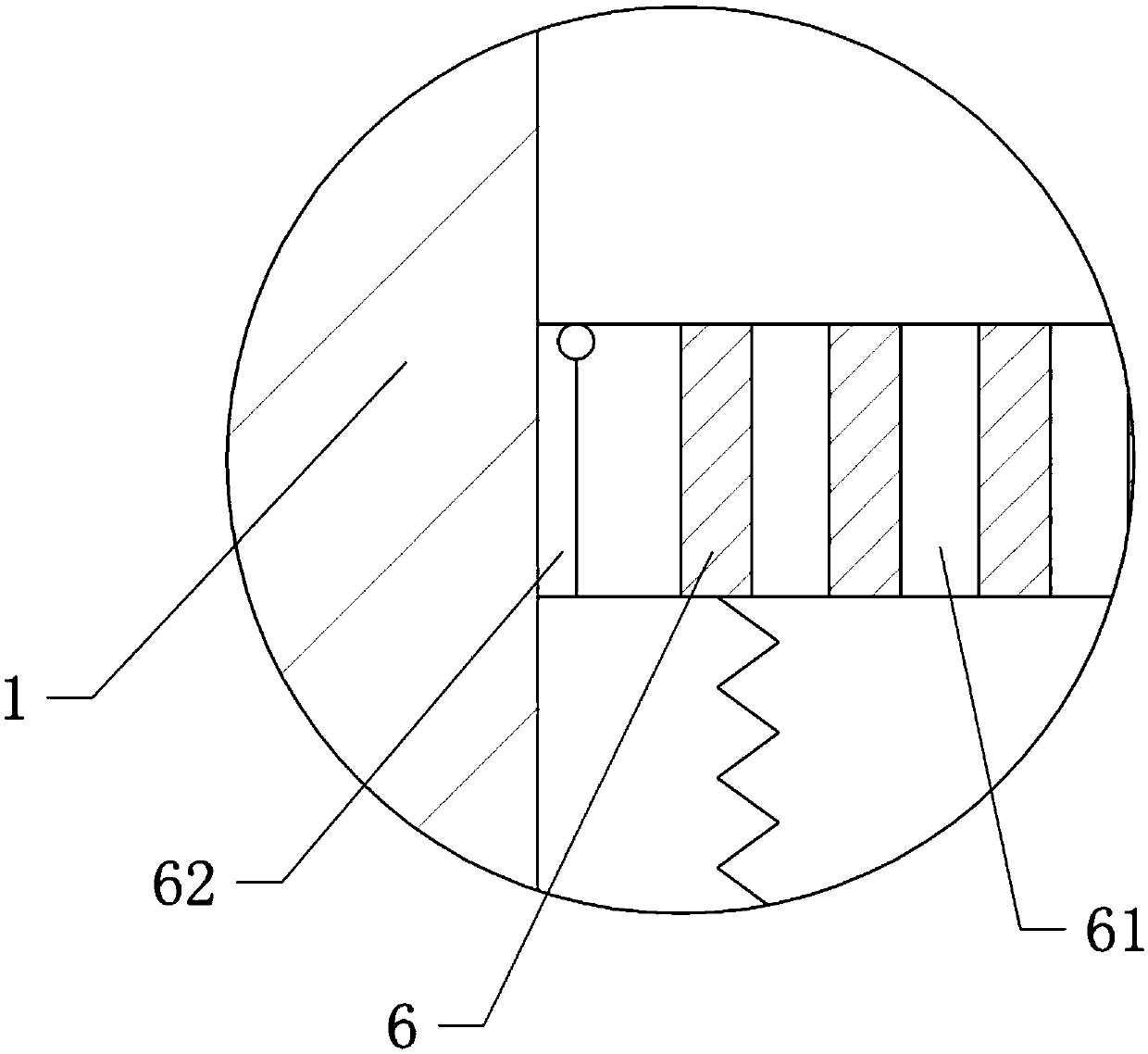

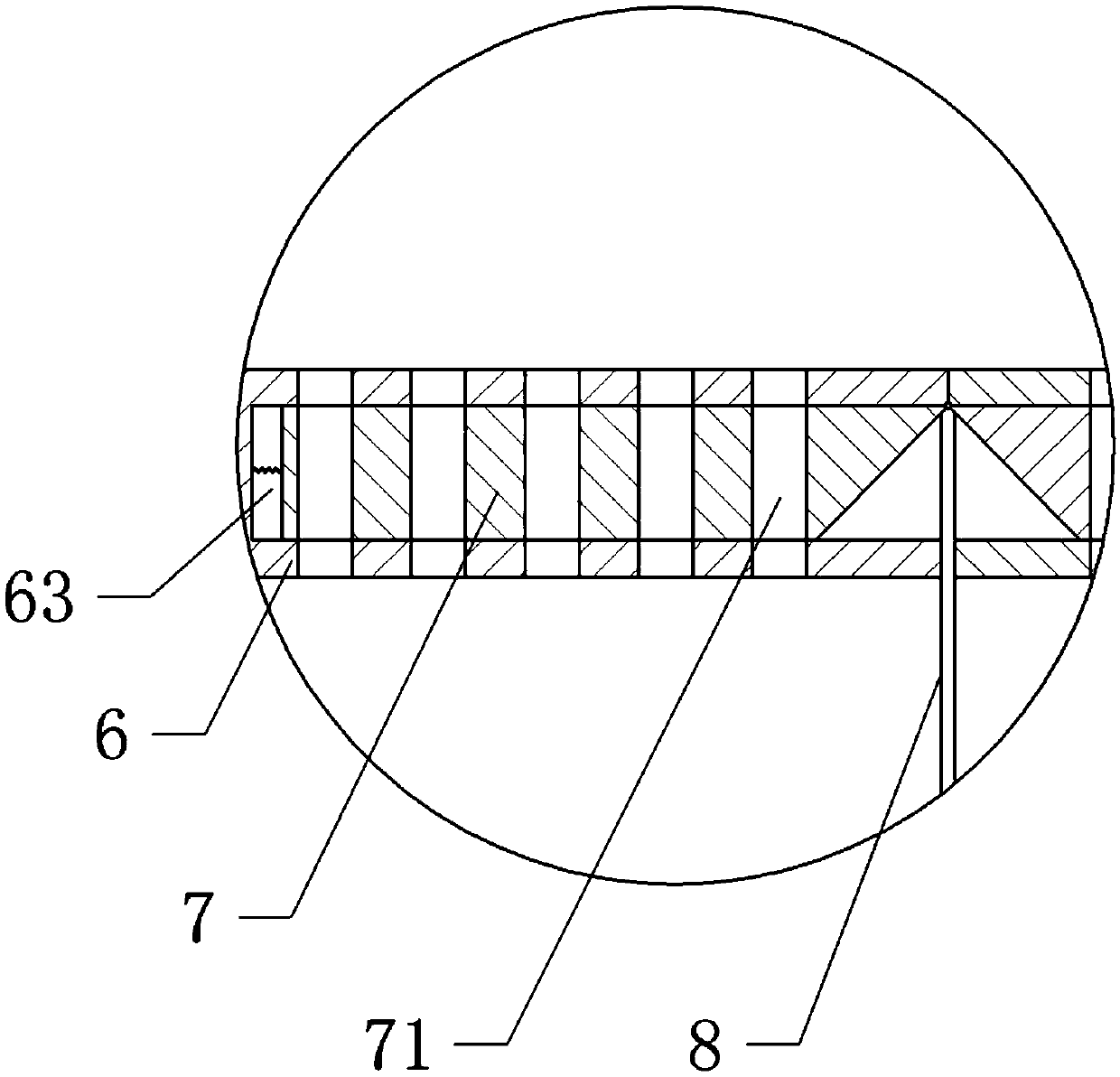

[0028] The reference signs in the drawings of the description include: crushing barrel 1, air inlet 11, air guide channel 12, material guide port 13, discharge port 14, extruding plate 2, extruding rod 21, stretching cover 22, guide Cover 3, turntable 4, crank 41, connecting rod 42, slide block 43, pole 44, crushing shaft 5, crushing roller 51, support plate 6, through hole 61, sliding block 62, chute 63, support block 64, block Plate 7, blanking hole 71, support rod 8.

[0029] The embodiment is basically as attached figure 1 Shown:

[0030] Raw material processing equipment for cattle feed production, including a frame and a crushing barrel 1 fixed on the frame. The crushing barrel 1 is provided with a crushing part, a guide cover 3, a crushing part and a screening part in sequence from top to bottom, and the guide cover 3 Inverted frustum shape. The crushing part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com