Built-in steel plate and reactive powder concrete composite shear wall

A technology of combined shear wall and active powder, applied in the direction of wall, building components, earthquake resistance, etc., can solve the problems of reducing the ductility and energy dissipation capacity of combined shear wall, reducing the seismic performance of concrete structures, affecting normal use and durability, etc. , to achieve the effect of easy control of processing quality, improved ductility and energy consumption, and improved ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

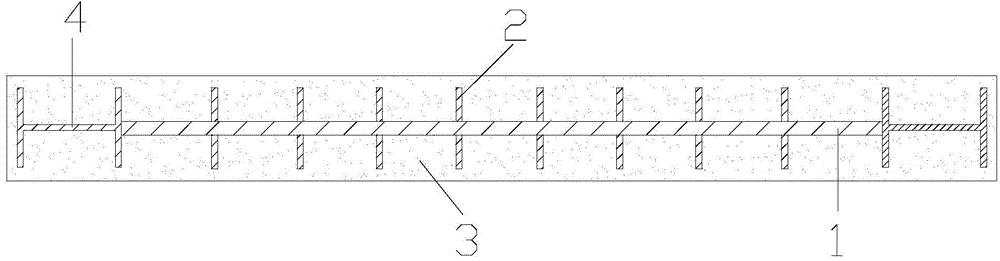

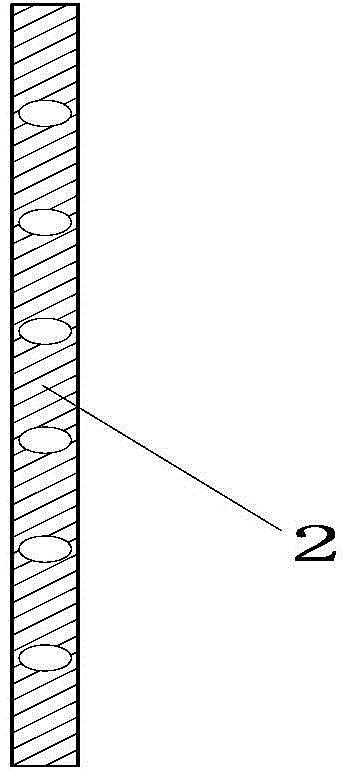

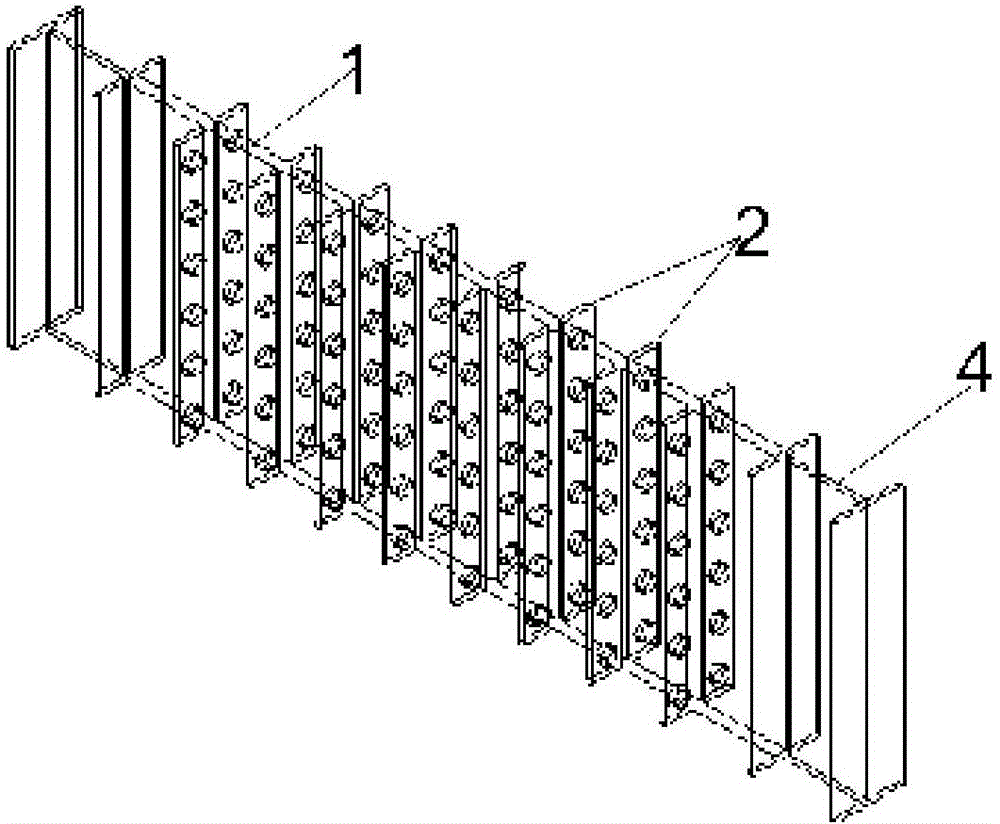

[0024] see Figure 1 to Figure 3 , the active powder concrete composite shear wall with built-in steel plate provided by the present invention comprises a built-in steel plate 1, the built-in steel plate 1 is a single-layer steel plate, several rows of stiffeners 2 with holes are arranged on both sides of the built-in steel plate 1, and on the stiffener 2 with holes A number of elliptical through-holes are evenly opened, the two ends of the built-in steel plate 1 are welded with I-shaped steel, the built-in steel plate 1, the stiffener with holes 2 and the shaped steel 4 are wrapped in the active powder concrete 3, and the built-in steel plate 1 passes through the stiffener with holes 2 Tight connection with reactive powder concrete 3. The stiffeners 2 with holes and the section steel 4 are arranged along the full height of the built-in steel plate 1 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com