Non-power rotation aeration disc for sewage treatment

A technology of power rotation and sewage treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve problems such as easy blockage, small aeration range, large diffusion resistance, etc., to achieve Good diffusion, increased aeration area, beneficial to the effect of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

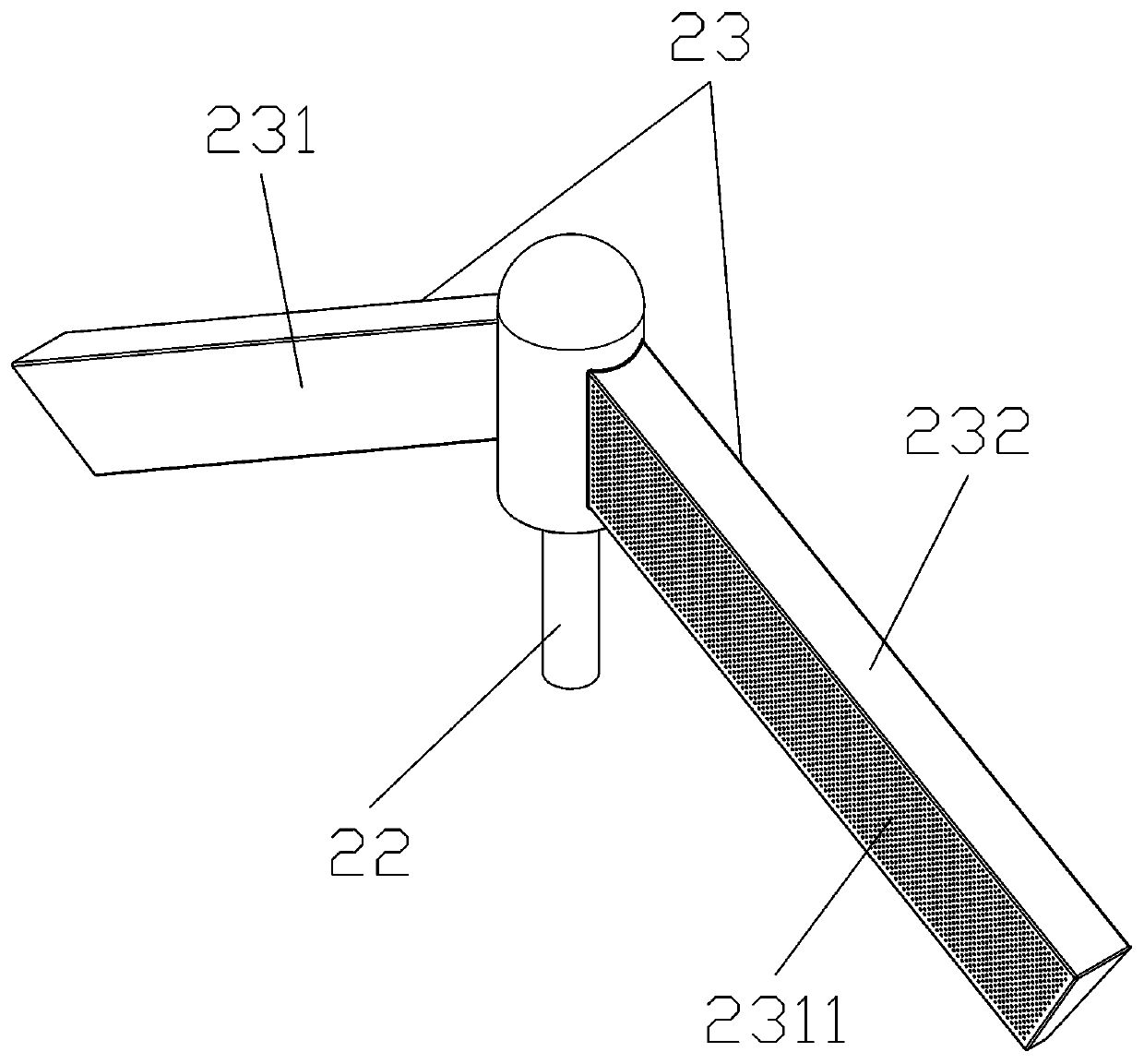

[0049] Such as image 3 , the first ventilation holes 2311 are distributed on the entire side surface 231 of the aeration blade 23 .

[0050] Therefore, the unpowered rotating aeration disc used for sewage treatment only provides side air outlet, which can improve the rotating power and prevent the clogging of the air holes; in particular, the diameter of the first air holes 2311 gradually increases from the direction away from the hollow shaft 22 , can provide better power to the blade.

Embodiment 2

[0052] Such as Figure 4 , Figure 5 , the first ventilation holes 2311 are distributed on the side 231 of the aeration blade 23 away from the end of the hollow shaft 22 , and the second ventilation holes 2321 are evenly distributed on the entire top surface 232 or / and bottom surface of the aeration blade 23 .

[0053] Thus, the non-powered rotating aeration disc used for sewage treatment is aerated upwards or / and downwards through the second air holes 2321 on the top surface 232 or / and bottom surface, and provided by the first air holes 2311 on the side 231. Rotational power.

[0054] Such as image 3 , Figure 4 , Figure 5 , Figure 6 , the top surface 232 of the aeration blade 23 is inclined from top to bottom in the direction away from the hollow shaft 22 .

[0055] As a result, when debris falls from above to the top surface 232 , it is easier to slide down from the inclined surface, which can better prevent the second air hole 2321 from being blocked.

Embodiment 3

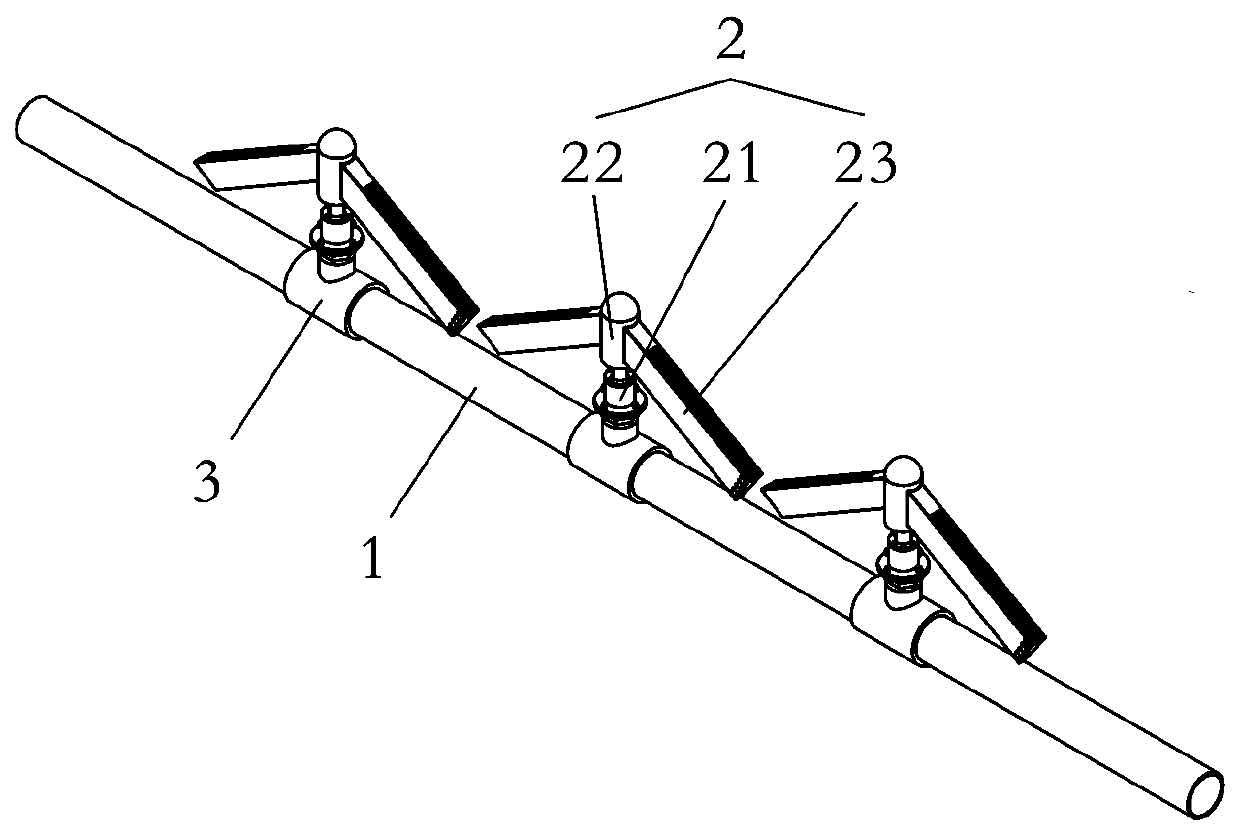

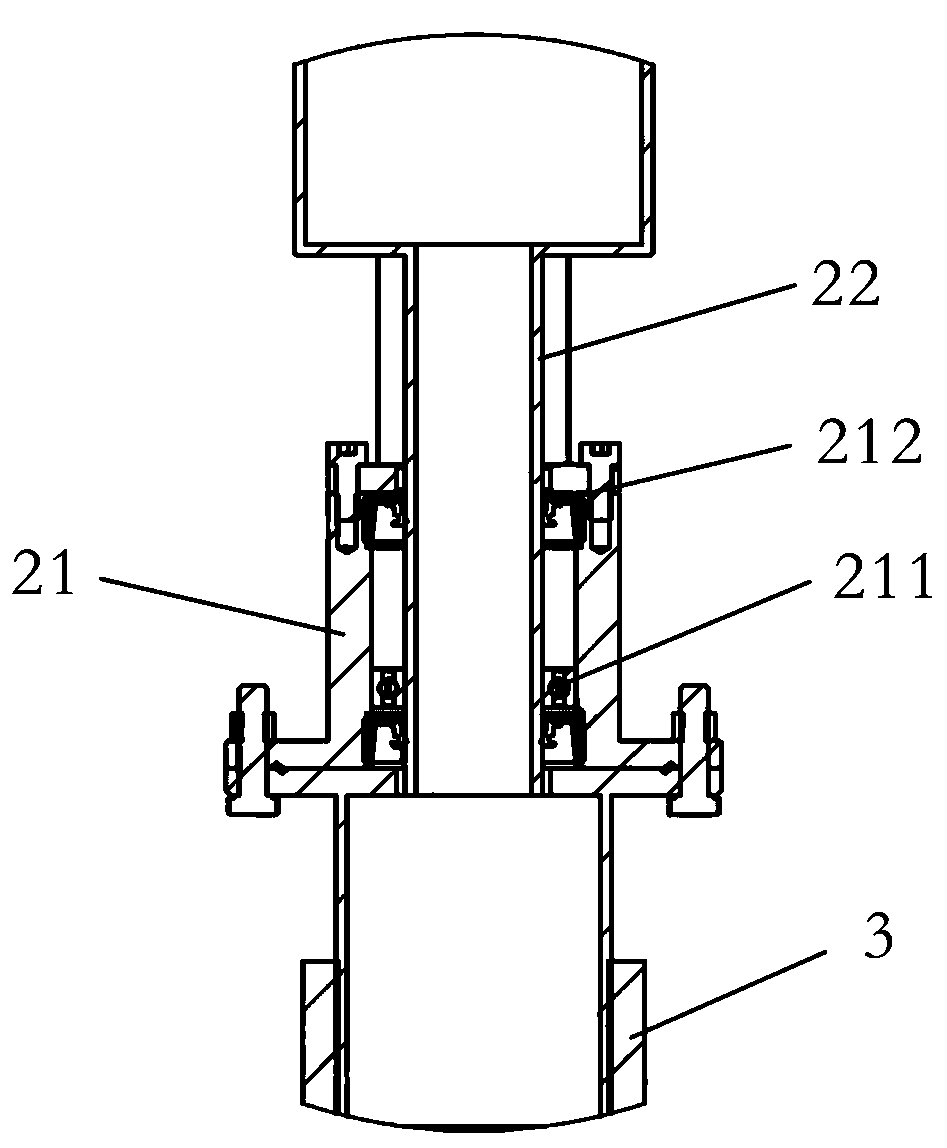

[0057] Such as Figure 6 , the hollow transition pipes 21 are connected at both ends of the air pipe 1, and the hollow transition pipes 21 at both ends are respectively connected with two air pipes 1.

[0058] Therefore, if more aeration volume is desired, the hollow transition pipe 21 and the ventilation pipe 1 can be installed at the upper and lower ends, which is especially suitable for the case where multiple sets of aeration blades 23 are arranged in the axial direction of the hollow rotating shaft 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com