Preparation method of high-strength ceramic tile gum for high-temperature zone

A high-temperature, high-strength technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., to enhance bond strength, facilitate construction, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

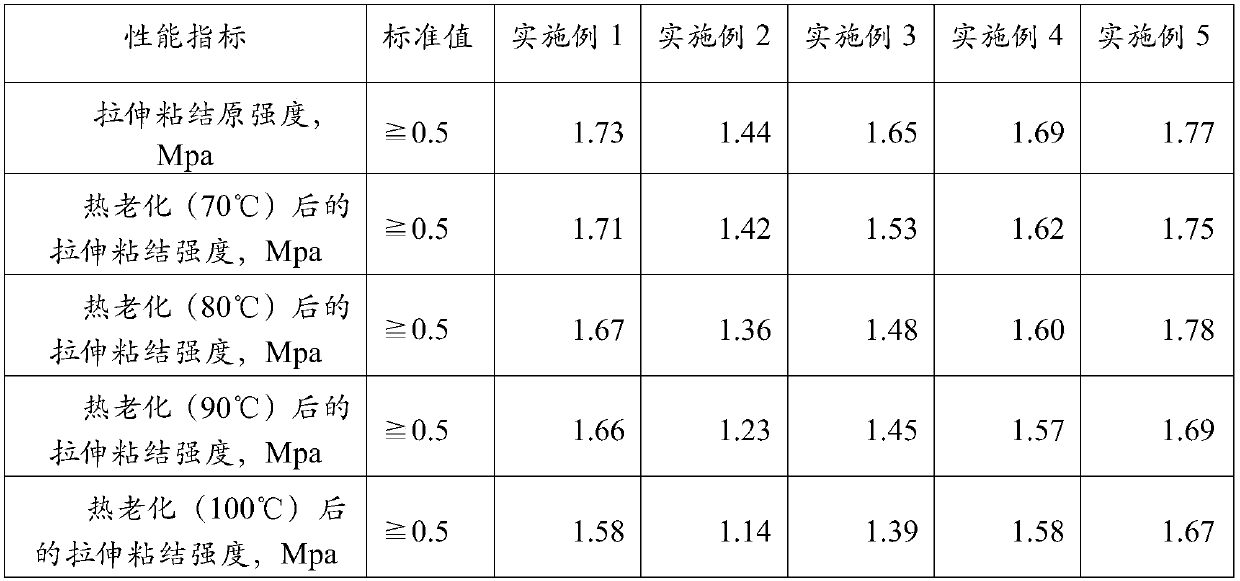

Examples

Embodiment 1

[0028] A high-strength ceramic tile adhesive used in high-temperature areas, comprising the following components in parts by weight:

[0029] 50 parts of emulsion, 40 parts of quartz sand, 10 parts of fly ash, 0.19 parts of thickener, 0.9 parts of water reducer and 0.2 parts of preservative;

[0030] Wherein, the emulsion is formed by mixing 20 parts by weight of styrene-acrylic emulsion and 30 parts by weight of styrene-butadiene emulsion, the solid content of the styrene-acrylic emulsion is greater than 48%, and the solid content of the styrene-butadiene emulsion is greater than 50%.

[0031] Wherein, the quartz sand is 40 mesh quartz sand, and the thickener is hydroxypropyl methylcellulose.

[0032] The present invention also provides a method for preparing the above-mentioned high-strength tile adhesive used in high-temperature areas, comprising the following steps:

[0033] Step 1, mixing the quartz sand and fly ash of the formula portion, after stirring evenly, to obtai...

Embodiment 2

[0038] A high-strength ceramic tile adhesive used in high-temperature areas, comprising the following components in parts by weight:

[0039] 60 parts of emulsion, 35 parts of quartz sand, 5 parts of fly ash, 0.22 parts of thickener, 0.8 parts of water reducing agent and 0.3 parts of preservative;

[0040] Wherein, the emulsion is formed by mixing 25 parts by weight of styrene-acrylic emulsion and 35 parts by weight of styrene-butadiene emulsion, the solid content of the styrene-acrylic emulsion is greater than 48%, and the solid content of the styrene-butadiene emulsion is greater than 50%.

[0041] Wherein, the quartz sand is 60-mesh quartz sand, and the thickener is hydroxypropyl methylcellulose.

[0042] The present invention also provides a method for preparing the above-mentioned high-strength tile adhesive used in high-temperature areas, comprising the following steps:

[0043] Step 1, mixing the quartz sand and fly ash of the formula portion, after stirring evenly, to...

Embodiment 3

[0048] A high-strength ceramic tile adhesive used in high-temperature areas, comprising the following components in parts by weight:

[0049] 65 parts of emulsion, 27 parts of quartz sand, 8 parts of fly ash, 0.21 part of thickener, 0.7 part of water reducing agent and 0.4 part of preservative;

[0050] Wherein, the emulsion is formed by mixing 25 parts by weight of styrene-acrylic emulsion and 40 parts by weight of styrene-butadiene emulsion, the solid content of the styrene-acrylic emulsion is greater than 48%, and the solid content of the styrene-butadiene emulsion is greater than 50%.

[0051] Wherein, the quartz sand is 70 mesh quartz sand, and the thickener is hydroxypropyl methylcellulose.

[0052] The present invention also provides a method for preparing the above-mentioned high-strength tile adhesive used in high-temperature areas, comprising the following steps:

[0053] Step 1, mixing the quartz sand and fly ash of the formula portion, after stirring evenly, to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com