Load bearing board and degreasing technology of zirconia ceramic injection molding blank and application thereof

The technology of zirconia ceramics and degreasing process is applied in the field of degreasing process of setter plate and zirconia ceramic injection molding embryo body, which can solve the problems of large deformation, cracking, and unstable shrinkage of injection molding embryo body, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0092] As a preferred embodiment of the present invention, the degreasing process of the zirconia ceramic injection molded body includes the following steps:

[0093] Step a): preheating: the zirconia ceramic injection molded body is gradually heated from room temperature to 130-145° C. over 3-5 hours to complete the preheating of the zirconia ceramic injection molded body;

[0094] Step b): pre-degreasing: heat preservation in the range of 130-145°C for 1-4h to complete pre-degreasing;

[0095] Step c): degreasing: after the pre-degreasing is completed, the temperature is gradually raised to 300-310° C. over 17-32 hours to complete the degreasing process of the zirconia ceramic injection molded body;

[0096] Step d): pre-firing: After the degreasing is completed, the temperature is gradually raised to 590-600° C. over 6-14 hours, and then kept for 1-3 hours to complete the pre-firing of the zirconia ceramic injection molded body;

[0097] Step e): Degreasing is completed af...

Embodiment 1

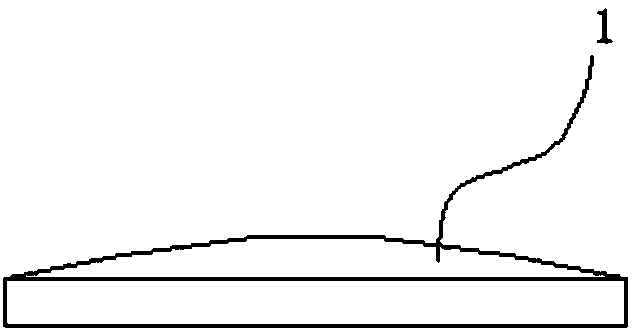

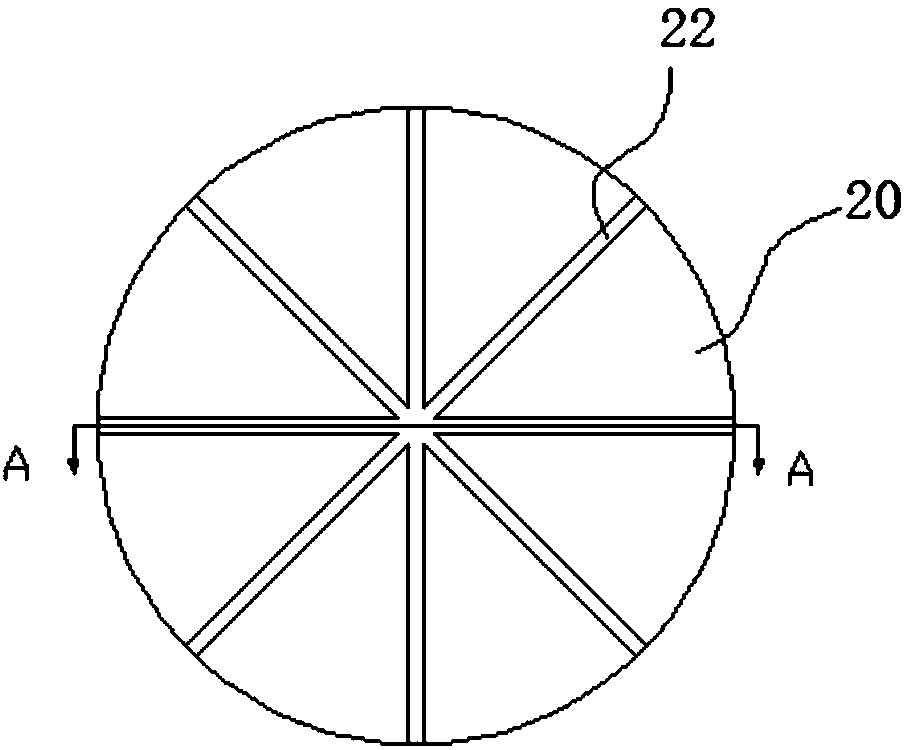

[0109] This embodiment is a setter, such as Figure 3-6 As shown, the shape of the base plate 10 of the setter plate is rectangular, and the specific size is 350 mm × 180 mm × 5 mm. On the base plate 10, 24 circular positioning bosses 11 with an outer diameter of 5 mm and a height of 1 mm are made, which are evenly distributed over the entire area according to the area. The surface of the substrate 10 (except for the code angle position); make a circular bearing platform 20 for placing the zirconia ceramic injection molded body, the specific dimensions of the bearing platform 20 are: outer diameter 40mm, thickness 4.0mm, the upper Exhaust grooves 22 are opened on one side of the surface, the width of the exhaust grooves 22 is 1.0mm, the depth of the exhaust grooves 22 is 0.5mm, the number of exhaust grooves 22 is 5, and the spacing between two exhaust grooves 22 is equal. A circular positioning groove 21 is provided at the center of the lower surface of the carrying platform 2...

Embodiment 2

[0111] This embodiment is a degreasing process of zirconia ceramic injection molded embryo body for the back shell of a mobile phone, and the specific degreasing process curve refers to Figure 7 , including the following steps:

[0112] Step a): Preheating: first place the zirconia ceramic injection molded body on the setter provided in Example 1, and then place it in a heating furnace to gradually raise the temperature of the zirconia ceramic injection molded body from room temperature to 140°C over 4 hours Complete the preheating of the zirconia ceramic injection molded body;

[0113] Step b): pre-degreasing: heat preservation at 140°C for 1.5 hours to complete pre-degreasing;

[0114] Step c): degreasing: after the pre-degreasing is completed, the temperature is gradually raised to 300° C. over 25 hours to complete the degreasing process of the zirconia ceramic injection molded body;

[0115] Step d): pre-firing: After the degreasing is completed, the temperature is grad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com