A kind of high solid content ddi-htpb propellant with improved process performance and its processing technology

A technology with high solid content and process performance, applied in explosive processing equipment, offensive equipment, compressed gas generation, etc., can solve problems such as poor process performance, achieve good mechanical properties, ensure safety performance, and be beneficial to actual production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

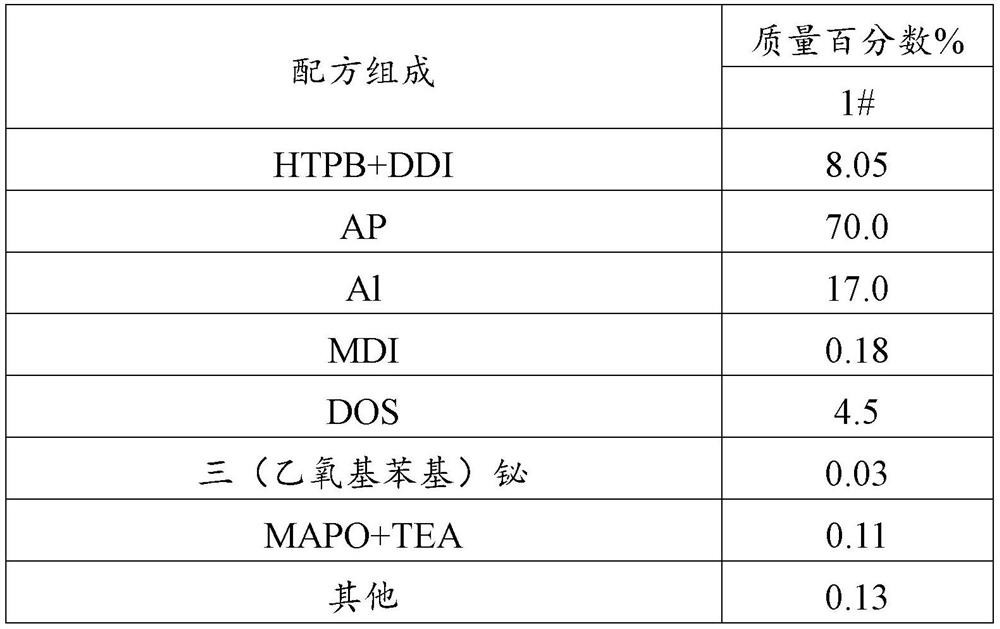

[0029] A high estimate of process performance DDI-HTPB propellant, which is shown in Table 1.

[0030] Table 1 Proposal formula composition

[0031]

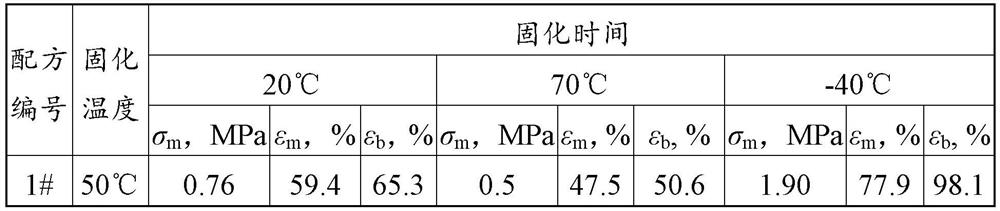

[0032] The main processing process of the above-mentioned formulation production propellant is: the mixed temperature of the slurry is 50 ° C, adding MDI and DDI after adding MDI and DDI after the oxidant AP is added, and then continues to mix 55min, the process performance test results of the resulting propulsion phama Table 2, where η is a slurry viscosity.

[0033] Table 2 Process Performance Test Results of Progressive Formulation Phase

[0034] Hybrid process Time, H 1h 3h 5h test temperature 1# η / pa · 582.3 617.1 703.9 50℃

[0035] As can be seen from Table 2, the solid content of the propellant is as high as 87%, adding 0.18% of the isocyanate curing agent MDI and the curing catalyst, and the propellant formulation of DDI is a curing agent, mixed under 50 degrees. The process of the resulting...

Embodiment 2

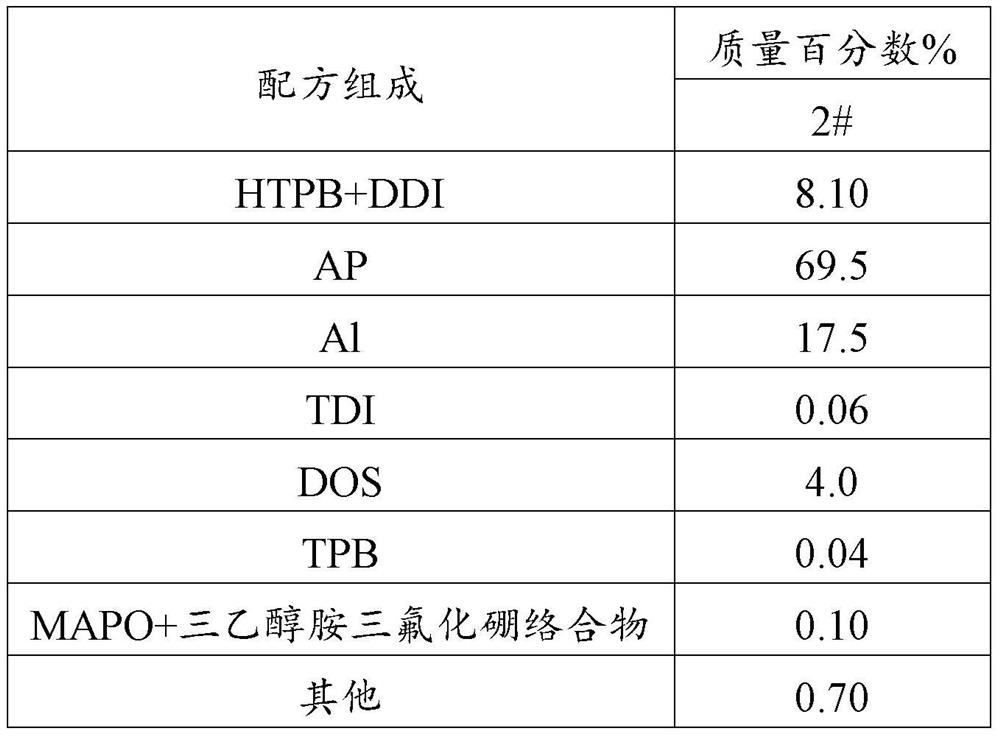

[0041] A high estimate of process performance DDI-HTPB propellant, which is shown in Table 4.

[0042] Table 4 propellant formulation

[0043]

[0044] The main processing process of the above formulation of the formulation of the formulation is: the mixed temperature of the slurry is 50 ° C, and TDI and DDI are added after 15 minutes after the oxidant AP is added, and then the process performance test results of the resulting propulsion phama will be given. table 5.

[0045] Table 5 Process performance test results of propellant formula

[0046] Hybrid process Time, H 1h 3h 5h test temperature 2# η / pa · 472.5 458.7 591.3 50℃

[0047] As can be seen from Table 5, the solid content of the propellant is as high as 87.5, and 0.06% highly active isocyanate curing agent TDI and the catalyst are mixed with DDI as a curing agent, mixed under 50 degrees, resulting The process of the propellant is very good, and the viscosity of the phama after 5 hours und...

Embodiment 3

[0053]A high estimate of process performance DDI-HTPB propellant, which is shown in Table 7.

[0054] Table 7 propellant formulation

[0055]

[0056] The main processing process of the formulation of the formulation of the above-mentioned formulation of the propellant is: the mixed temperature of the slurry is 50 ° C, and TDI and DDI are added after 12 minutes after the oxidant AP is added, and then the process performance test results of the resulting propulsion phama are obtained. Table 8.

[0057] Table 8 Process Performance Test Results of Propellant Formulation Phase

[0058] Hybrid process Time, H 1h 3h 5h test temperature 2# η / pa · 491.1 420.2 534.6 50℃

[0059] As can be seen from Table 8, the solid content of the propellant is as high as 86.5, and 0.23% highly active isocyanate curing agent TDI and the cure catalyst, the propellant formulation of DDI is a curing agent, mixed under 50 degrees, resulting The process of the propellant is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com