Self-repairing polymer electrolyte matrix and preparation method thereof, self-repairing polymer electrolyte, lithium ion battery and application thereof

A self-healing, polymer technology, applied in the direction of electrolytes, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of low energy density of energy storage devices, limited operating voltage window range of aqueous polymer electrolytes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0113] According to a second aspect of the present invention, there is provided a method for preparing the above-mentioned self-healing polymer electrolyte matrix, comprising the following steps:

[0114] Inorganic nano-additives and other polymers are grafted on the self-healing polyurethane to obtain a self-healing polymer electrolyte matrix.

[0115] A self-healing polymer electrolyte matrix can be prepared by grafting inorganic nano-additives and other polymers on self-healing polyurethane. The preparation method is simple.

[0116] In one embodiment, the preparation method of self-healing polymer electrolyte matrix comprises the following steps:

[0117] (a) dissolving the inorganic nano-additive in the organic solvent, then adding diisocyanate, and obtaining the modified inorganic nano-additive after the reaction;

[0118] (b) in the solution that step (a) obtains, add bishydroxyl compound, obtain the polyurethane grafted with inorganic nano-additive after reaction;

...

Embodiment 1

[0149] 1. Self-healing polymer electrolyte matrix

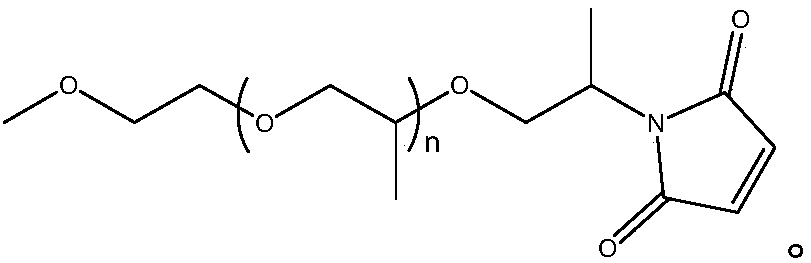

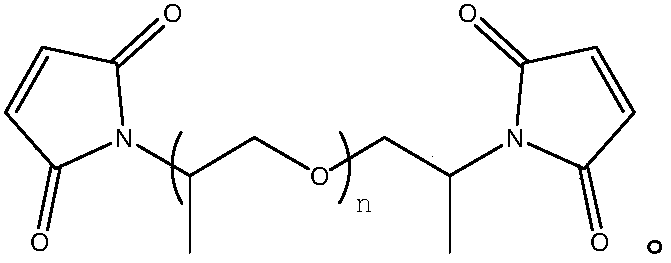

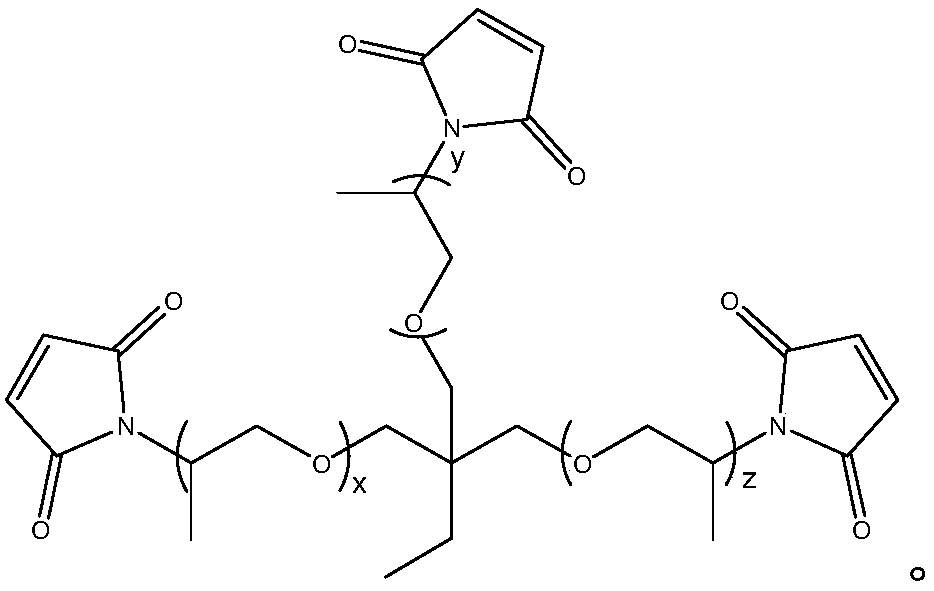

[0150] A self-healing polymer electrolyte matrix consisting of graphene oxide (500nm-2μm in size), self-healing polyurethane and PVDF-HFP (Aldrich, M w ~455000, M n ~110000); graphene oxide and PVDF-HFP are grafted on the self-healing polyurethane, and the self-healing polyurethane is a furan-maleimide structural self-healing polyurethane.

[0151] 2. Preparation of self-healing polymer electrolyte matrix

[0152] The preparation method of the self-healing polymer electrolyte matrix comprises the following steps:

[0153] (a) Dissolve 20mg of graphene oxide in 50mL of DMF (N,N-dimethylformamide), then add 2.0g of 4,4'-methylene bis(phenylisocyanate), 80°C Next N 2 The protection reaction was carried out for 2 hours to obtain the modified inorganic nano-additive.

[0154] (b) in the solution that step (a) obtains, add the polytetrahydrofuran glycol (PTMEG2000) of 8.0g, by constant pressure dropping funnel in N 2 Add drop...

Embodiment 2-5

[0163] The only difference between Examples 2-5 and Example 1 is that the types of furan derivatives are different, as shown in Table 1.

[0164] Table 1 Types of furan derivatives

[0165] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com