Electrolyte for reducing self-discharge of lithium ion battery and application

A lithium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of reducing battery self-discharge, complex process, reducing battery capacity, etc., to achieve the effect of reducing self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Electrolyte solution composition: the additive is LiBOB, the concentration is 0.03mol / L; the solvent is a mixture of propylene carbonate and diethyl carbonate (volume ratio 1:1), the lithium salt is LiPF6, the concentration is 1mol / L;

[0019] According to Li 3 V 2 (PO 4 ) 3 The mass ratio of conductive carbon black and binder is 8:1:1, dissolved in an appropriate amount of N-methylpyrrolidone and mixed evenly, coated with a wet film preparer to form an electrode film with a thickness of 0.15mm, and dried in vacuum Finally, slice the electrode sheets with a diameter of 12mm with a microtome, weigh and calculate the mass of the active material. At the same time, a lithium sheet was used as the negative electrode, Celgard 2500 was used as the diaphragm, 50 microliters of electrolyte was added, and a button battery was assembled in a glove box filled with argon, and then the assembled battery was subjected to an electrochemical test. Let it stand for 5 hours first, the...

Embodiment 2

[0021] Electrolyte solution composition: the additive is LiBOB, the concentration is 0.005mol / L; the solvent is a mixture of propylene carbonate and diethyl carbonate (volume ratio 1:1), the lithium salt is LiPF6, the concentration is 1mol / L;

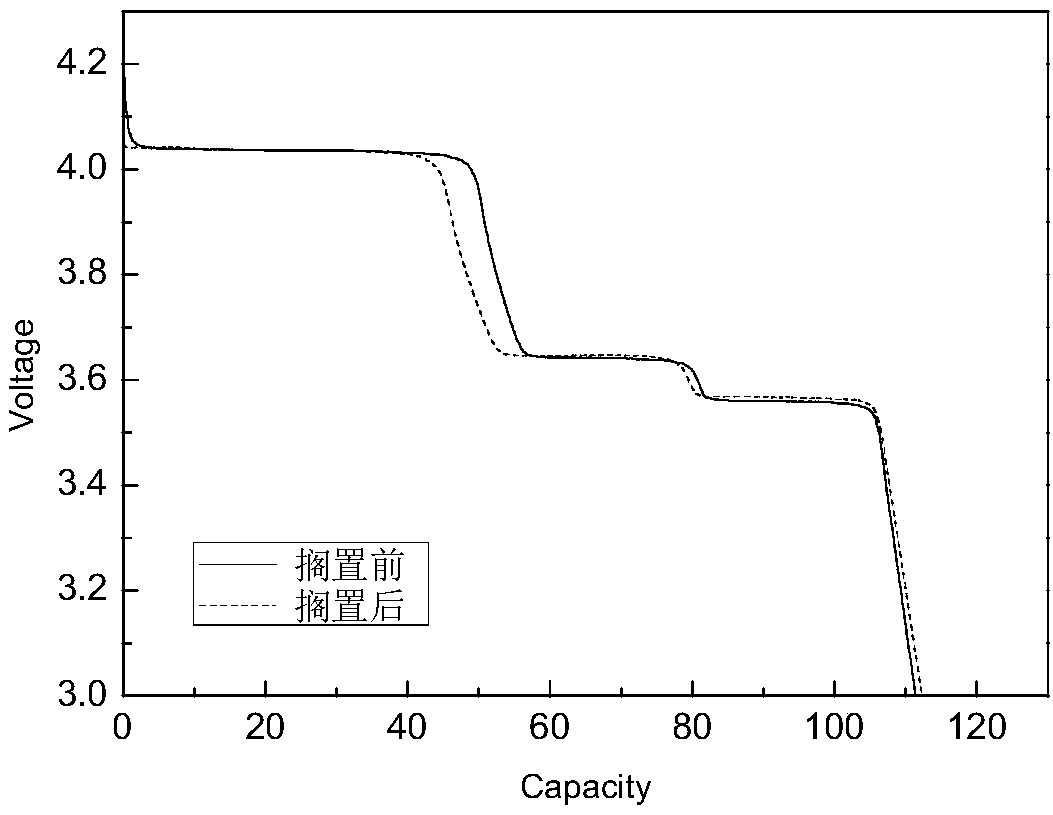

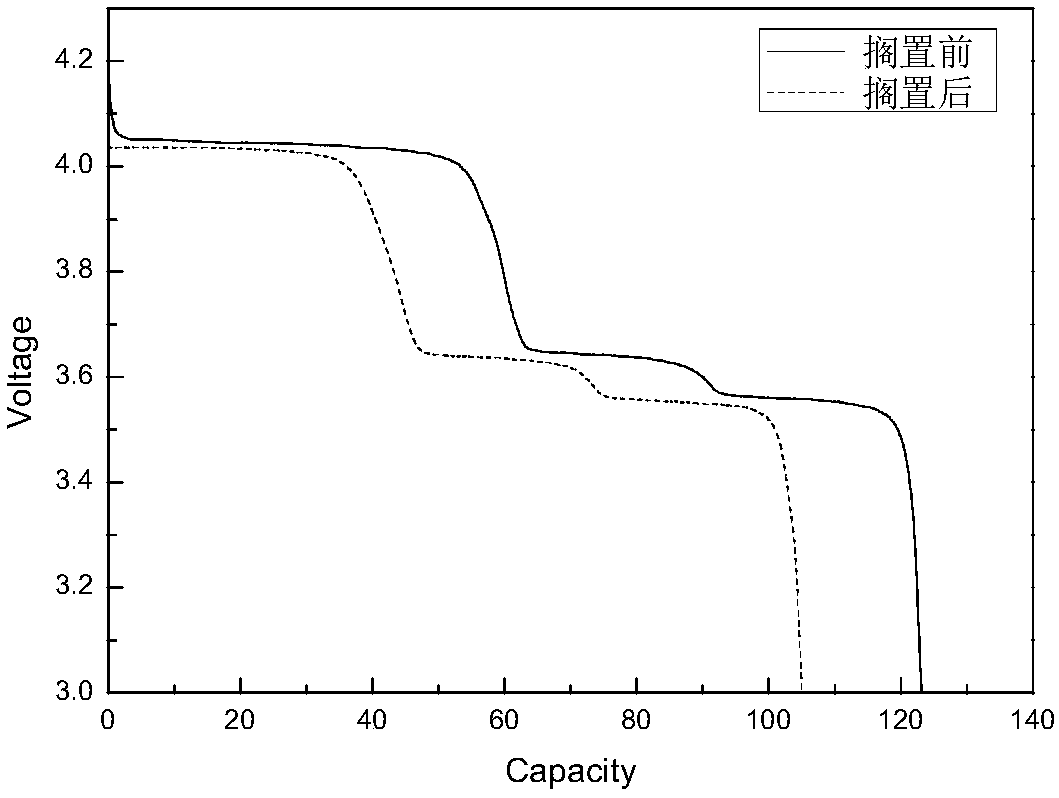

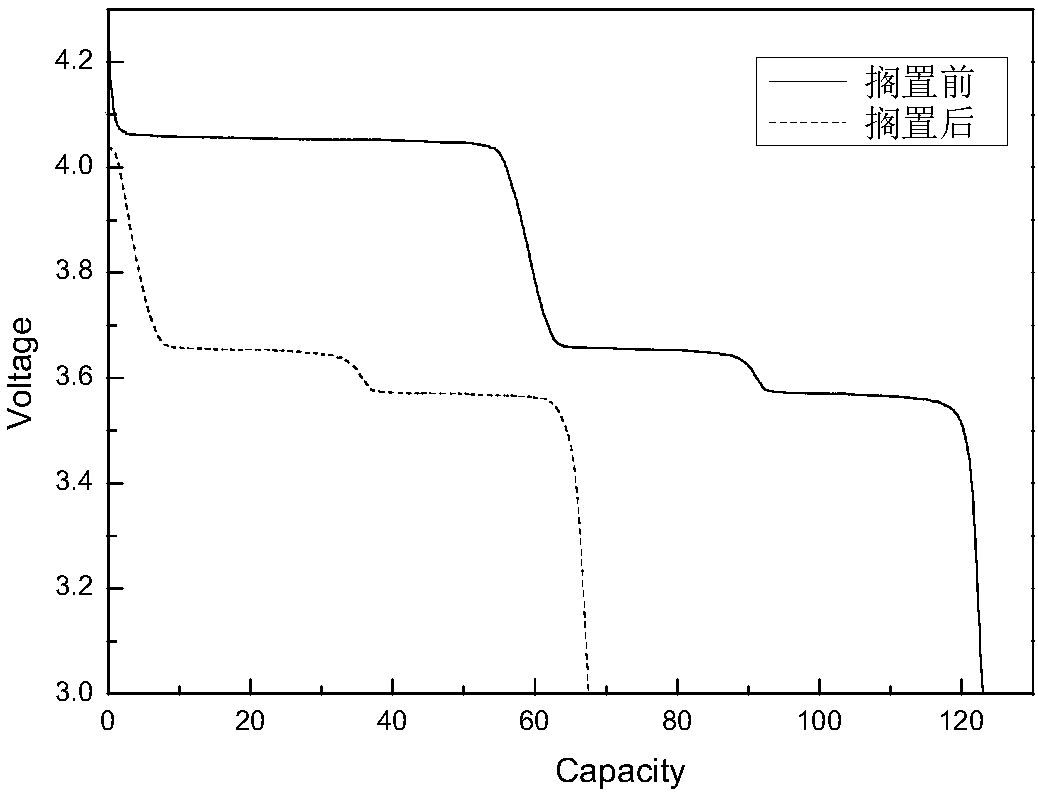

[0022] Test results such as figure 1 As shown, the self-discharge rate of the battery after shelving is 9%.

Embodiment 3

[0024] Electrolyte solution composition: the additive is LiBOB, the concentration is 0.05mol / L; the solvent is a mixture of propylene carbonate and diethyl carbonate (volume ratio 1:1), the lithium salt is LiPF6, the concentration is 1mol / L;

[0025] Test results such as figure 1 As shown, the self-discharge rate of the battery after shelving is 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com