Tin-containing negative electrode material, negative electrode, preparation method of negative electrode, negative electrode slurry, secondary battery and electric equipment

A technology of negative electrode material and negative electrode slurry, applied in secondary batteries, battery electrodes, negative electrodes, etc., can solve the problems of tin negative electrode pulverization and other problems, and achieve the effect of inhibiting volume expansion and pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The method is a conventional slurry preparation method, the process is mature and stable, and the operation is convenient.

[0063] In this embodiment, the negative electrode slurry can be prepared by, for example, the following method: Weigh the tin particles, binder and conductive agent according to a certain weight ratio, put each material in a mortar, add an appropriate amount of organic solvent dropwise and grind evenly, Obtain the negative electrode slurry.

[0064] In other embodiments of the present invention, the negative electrode slurry can be prepared by the following method: providing a suspension composed of tin particles and an organic solvent, and dissolving an optional coupling agent in the suspension, and then Add the binder and the conductive agent and mix uniformly to obtain the negative electrode slurry.

[0065] First add the coupling agent to the suspension composed of tin particles and organic solvents, so that the coupling agent can fully conta...

Embodiment 1

[0091] This embodiment is a negative electrode, which includes a negative electrode current collector and a negative electrode material layer formed on the surface of the negative electrode current collector. The raw materials of the negative electrode material layer include nano-tin particles, an elastic binder and a conductive agent. Wherein, the negative electrode current collector is tin foil, the elastic binder is calcium alginate, and the conductive agent is polyethylene oxide PEO.

[0092] The preparation method of this negative pole comprises the following steps:

[0093] S1) Weigh 0.05g of conductive agent polyethylene oxide PEO, dissolve it in 5ml of N-methylpyrrolidone (NMP) and mix evenly, then add 0.05g of elastic binder and mix evenly to form a homogeneous solution;

[0094] S2) After cleaning 0.4 g of nano-tin particles, add them to the above-mentioned homogeneous solution, and mix them uniformly to obtain negative electrode slurry;

[0095] S3) Coating the obt...

Embodiment 2~15

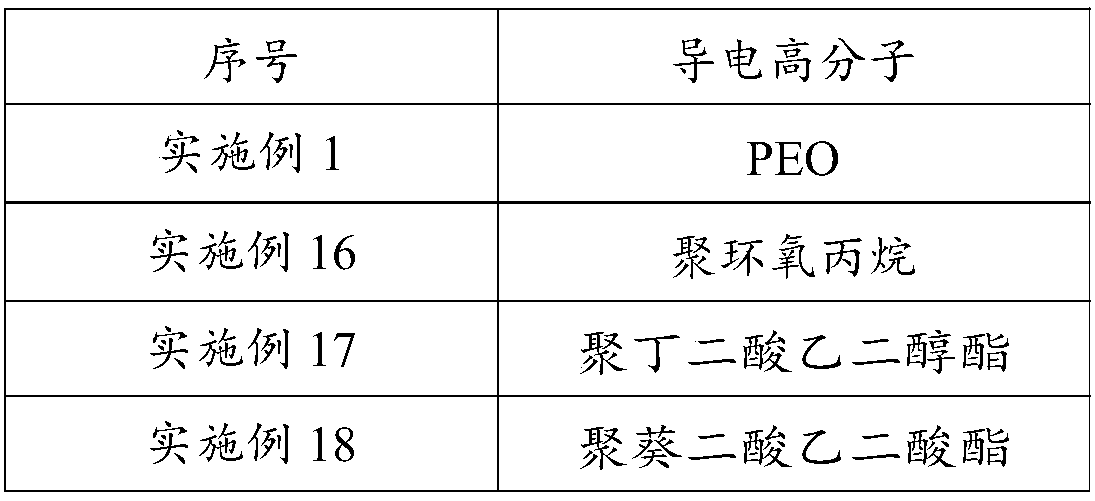

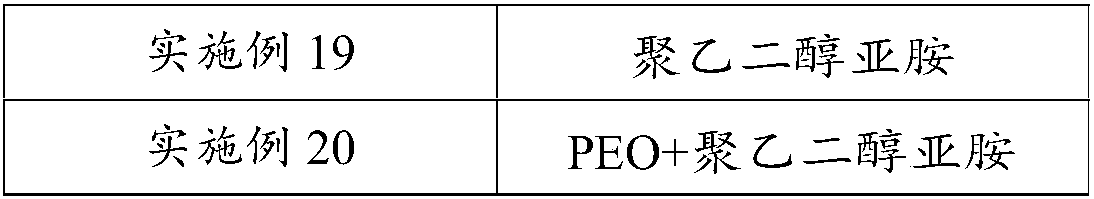

[0097] Examples 2 to 15 are negative electrodes respectively, and the difference from Example 1 is that the elastic binder used is different, and the others are the same as Example 1. The selection of specific elastic adhesives in Examples 1-15 is shown in Table 1.

[0098] Table 1

[0099]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com