Preparation method of super-hydrophilic/underwater super-oleophobic visible-light-driven anti-fouling membrane

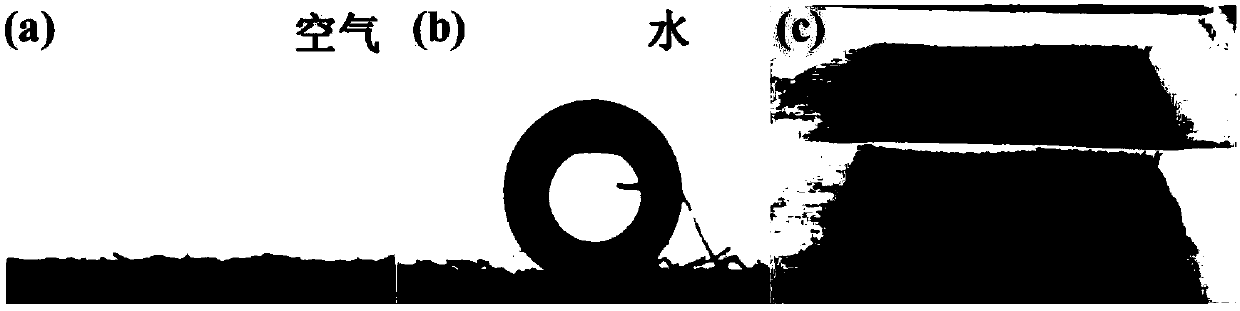

An underwater superoleophobic and visible light technology, which can be used in osmotic/dialysis water/sewage treatment, separation methods, chemical instruments and methods, etc., and can solve the problems of reducing the service life of membrane materials, reducing separation efficiency, and pore blocking and hydrophobicity. , to achieve the effect of stable performance, high separation efficiency and strong antifouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

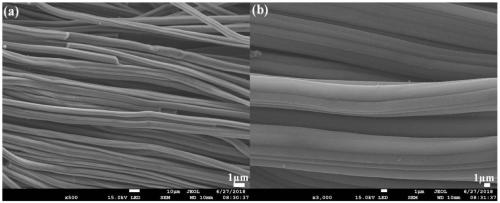

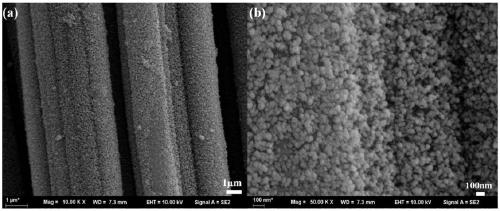

[0029] (1) First, disperse 20mL of N,N-dimethylformamide in 20mL of isopropanol and stir for 15min, then add 1mL of tetratintrum titanate, stir for 15min, then add 16mg of cobalt chloride hexahydrate, get mixed solution;

[0030] (2) Move the mixed solution to a polytetrafluoroethylene reactor, add carbon cloth, the area of the carbon cloth is 2.5cm x 3cm, heat the reaction, the temperature is 180°C, and the time is 18h. After cooling to room temperature naturally, take out the carbon cloth The composite was rinsed with deionized water, and dried in an oven at 60° C. for 12 hours to obtain a superhydrophilic / underwater superoleophobic visible light-driven antifouling film.

Embodiment 2

[0032] (1) First, disperse 10mL of N,N-dimethylformamide in 30mL of isopropanol and stir for 15min, then add 2mL of tetratintrum titanate, stir for 15min, then add 32mg of cobalt chloride hexahydrate, get mixed solution;

[0033] (2) Move the mixed solution to a polytetrafluoroethylene reaction kettle, add carbon cloth, the area of the carbon cloth is 2.5cm x 3cm, heat the reaction, the temperature is 200°C, and the time is 20h. After cooling to room temperature naturally, take out the carbon cloth The composite was rinsed with deionized water, and dried in an oven at 60° C. for 12 hours to obtain a superhydrophilic / underwater superoleophobic visible light-driven antifouling film.

Embodiment 3

[0035] (1) First, disperse 30mL of N,N-dimethylformamide in 40mL of isopropanol and stir for 15min, then add 3mL of tetratintrum titanate, stir for 15min, then add 48mg of cobalt chloride hexahydrate, get mixed solution;

[0036] (2) Move the mixed solution to a polytetrafluoroethylene reaction kettle, add carbon cloth, the area of the carbon cloth is 2.5cm x 3cm, heat the reaction, the temperature is 220°C, and the time is 22h. After cooling to room temperature naturally, take out the carbon cloth The composite was rinsed with deionized water, and dried in an oven at 60° C. for 12 hours to obtain a superhydrophilic / underwater superoleophobic visible light-driven antifouling film.

[0037] 2, the present invention will be further described below in conjunction with specific implementation examples:

[0038] In the present invention, the separation performance evaluation of the specific embodiment is carried out according to the following method: first, the prepared membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com