Synthetic method of zinc stannate nanomaterial for n-type transparent semiconductor film

A technology of nano-zinc stannate and synthesis method, which is applied in the fields of nanotechnology, tin compounds, and nanotechnology for materials and surface science, can solve problems such as affecting the light transmittance of nanocrystalline films, and achieve high electrical conductivity, high Effect of Electron Mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

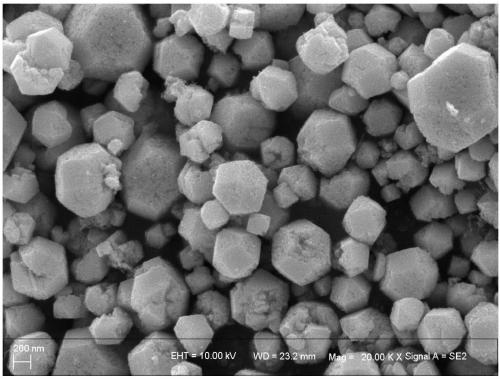

Embodiment 1

[0034] A kind of synthetic method for the nano zinc stannate material of n-type transparent semiconductor film, the steps are as follows:

[0035] 1) Preparation of molar ratio Zn:Sn=2:1 precursor

[0036] Weigh SnCl 4 12.547g, according to the ratio of each component of the above precursor solution according to SnCl 4 The amount to determine the ZnCl 2 amount. ZnCl 2 Easy to deliquescence, weighing must be fast, called ZnCl 2 13.12g and dissolved with an appropriate amount of deionized water (the amount of deionized water should not exceed the quality of the final precursor solution, generally enough to dissolve ZnCl 2 can), after stirring and cooling down to room temperature, the SnCl 4 with ZnCl 2 Quickly mix the aqueous solution, stir to dissolve and mix evenly and cool down to room temperature, then add an appropriate amount of deionized water (the final solution quality is determined according to the ratio of the components of the above-mentioned precursor solutio...

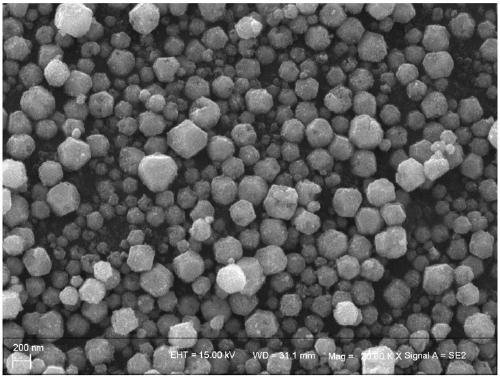

Embodiment 2

[0041] A kind of synthetic method for the nano zinc stannate material of n-type transparent semiconductor film, the steps are as follows:

[0042] 1) Preparation of molar ratio Zn:Sn=2:1 precursor

[0043] Consistent with embodiment 1 scheme

[0044] Weigh SnCl 4 12.55g, according to the ratio of each component of the above precursor solution according to SnCl 4 The amount to determine the ZnCl 2 amount. ZnCl 2 Easy to deliquescence, weighing must be fast, called ZnCl 2 13.12g and dissolved with an appropriate amount of deionized water (the amount of deionized water should not exceed the quality of the final precursor solution, generally enough to dissolve ZnCl 2 can), after stirring and cooling down to room temperature, the SnCl 4 with ZnCl 2Quickly mix the aqueous solution, stir to dissolve and mix evenly and cool down to room temperature, then add an appropriate amount of deionized water (the final solution quality is determined according to the ratio of the compone...

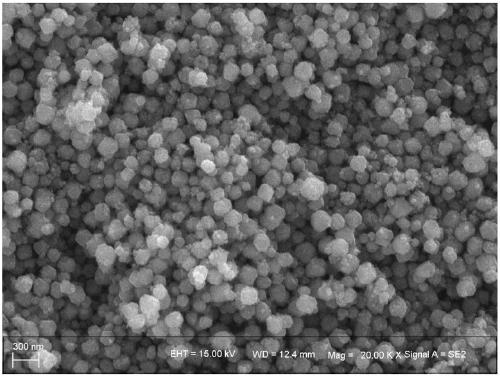

Embodiment 3

[0049] A kind of synthetic method for the nano zinc stannate material of n-type transparent semiconductor film, the steps are as follows:

[0050] 1) Preparation of molar ratio Zn:Sn=2:1 precursor

[0051] Consistent with embodiment 1 scheme

[0052] Weigh SnCl 4 12.547g, according to the ratio of each component of the above precursor solution according to SnCl 4 The amount to determine the ZnCl 2 amount. ZnCl 2 Easy to deliquescence, weighing must be fast, called ZnCl 2 13.12g and dissolved with an appropriate amount of deionized water (the amount of deionized water should not exceed the quality of the final precursor solution, generally enough to dissolve ZnCl 2 can), after stirring and cooling down to room temperature, the SnCl 4 with ZnCl 2 Quickly mix the aqueous solution, stir to dissolve and mix evenly and cool down to room temperature, then add an appropriate amount of deionized water (the final solution quality is determined according to the ratio of the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com