High-recovery circulating water blowdown water desalination treatment and recycling system for thermal power plant

A technology with high recovery rate and treatment system, which is applied in the field of desalination treatment and reuse system of high recovery rate circulating water and sewage in thermal power plants. and other problems, to achieve the effect of high water quality, high desalination rate, and zero discharge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

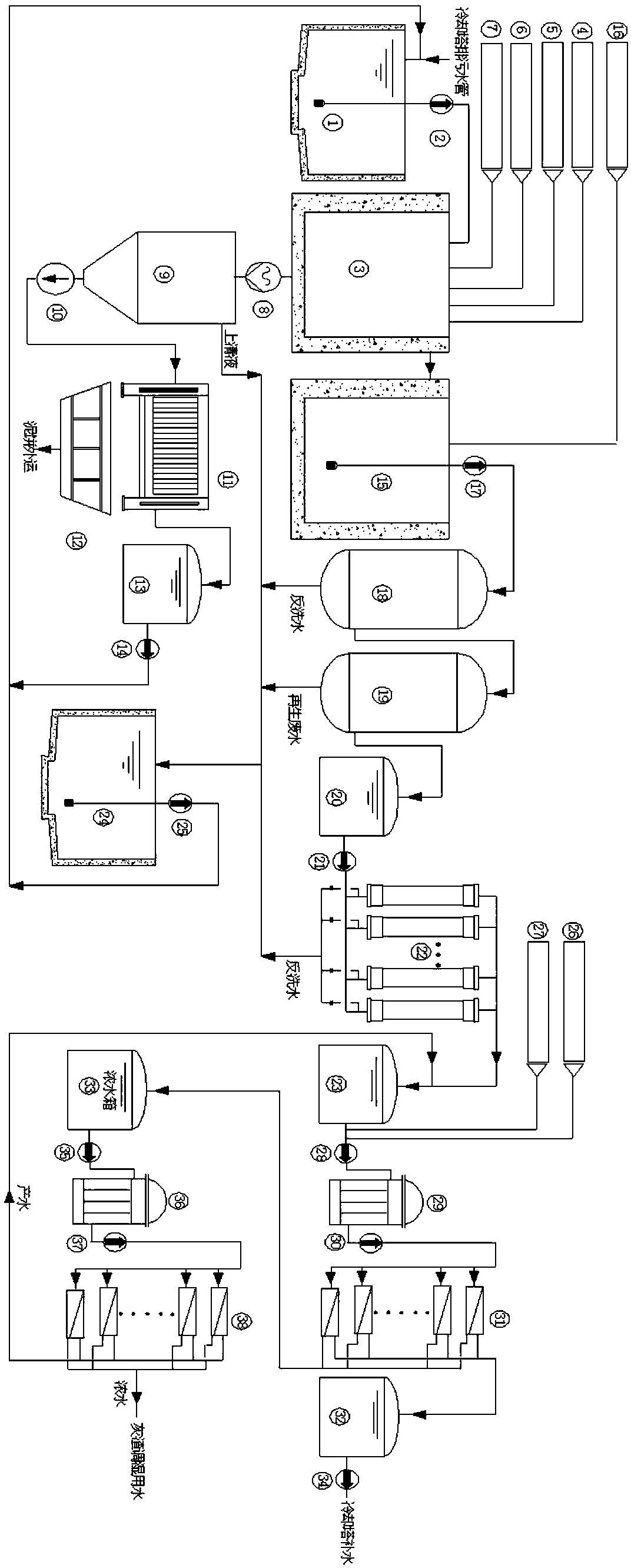

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

[0023] refer to figure 1 , the thermal power plant high recovery circulating water sewage desalination treatment and reuse system includes a circulating water sewage tank 1, a softening-coagulation clarification treatment system, an intermediate pool 15, a filtration system, a clean water tank 20, and an ultrafiltration treatment system , ultrafiltration water production tank 23, roll type reverse osmosis treatment system, fresh water tank 32, disc tube type reverse osmosis treatment system, waste water recovery tank 24 and sludge treatment system; the outlet of circulating water drainage tank 1 is softened-coagulation clarification treatment The system is connected to the inlet of the intermediate pool 15, the outlet of the intermediate pool 15 is connected to the inlet of the filtration system, the clean water outlet of the filtration system is connected to the inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com