Three-phase heating non-stick oily sludge pyrolysis device

A non-stick, three-stage technology, used in pyrolysis treatment of sludge, indirect heating and dry distillation, petroleum industry, etc., can solve the problems of coking of the device, inability to ensure that the discharge meets the standard, and the discharge after treatment does not meet the standard, etc., and achieves savings. The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

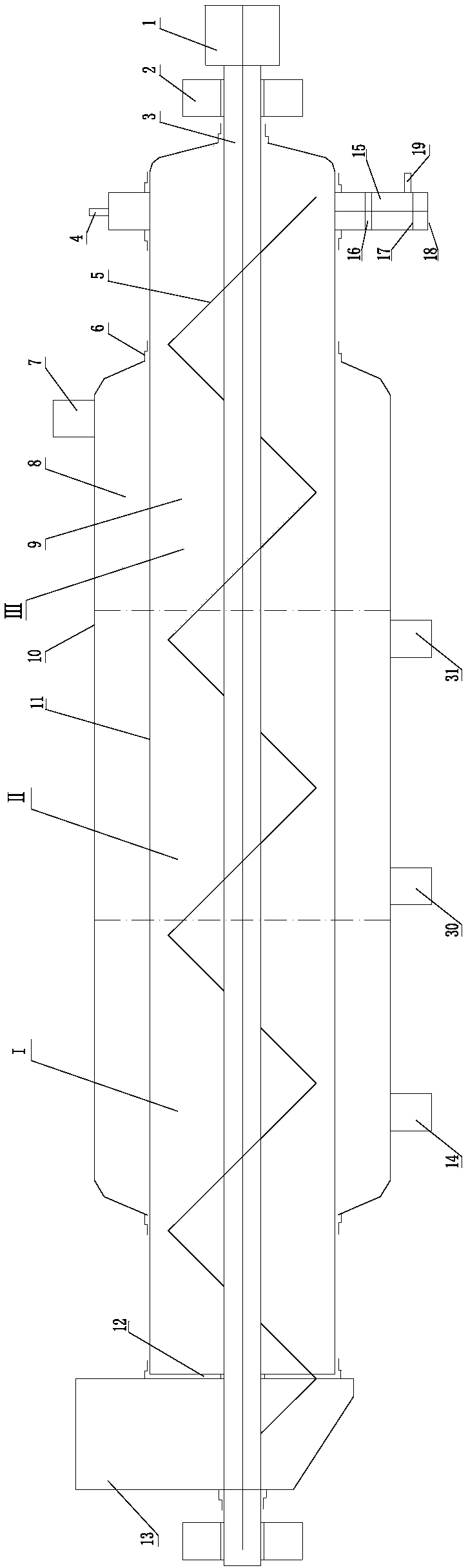

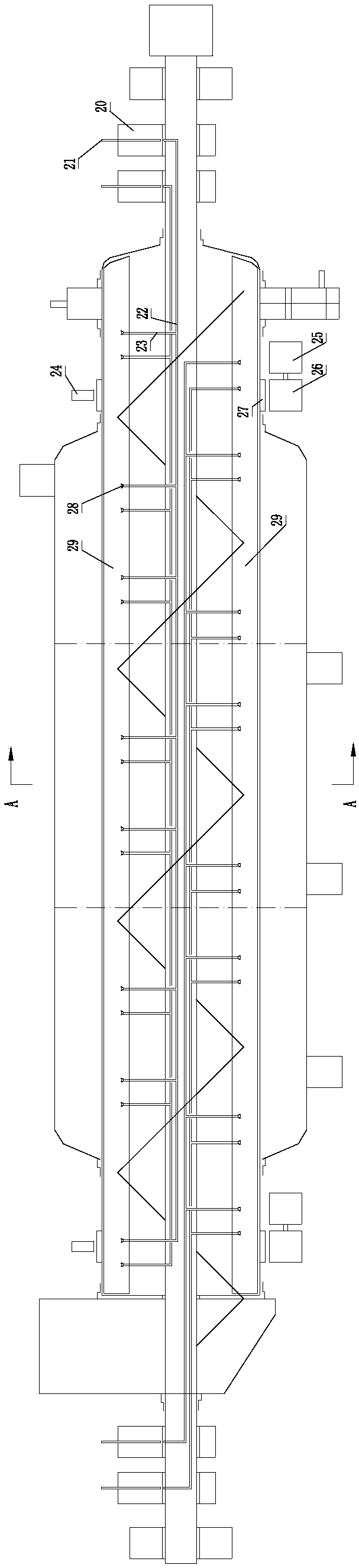

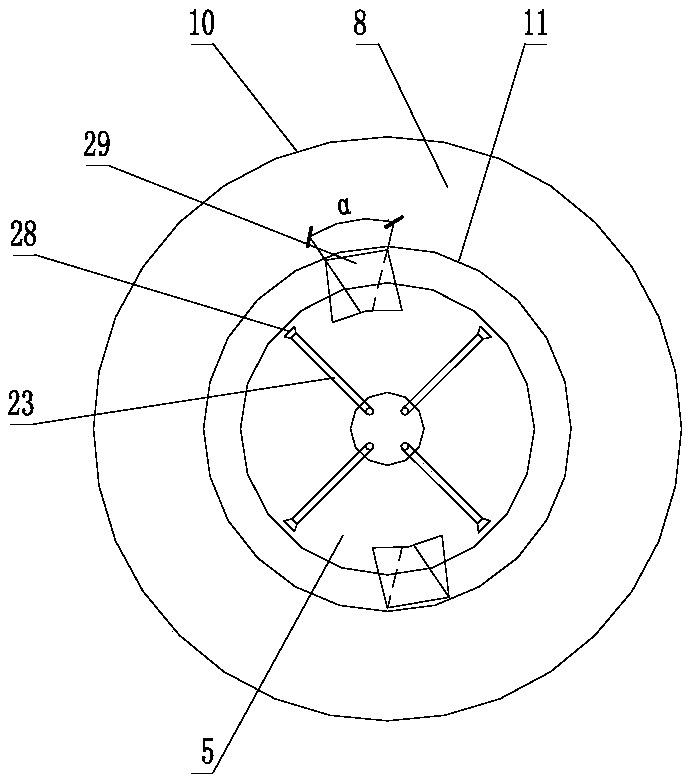

[0019] Depend on Figure 1 to Figure 3 As shown, a three-stage heating non-stick pan oily sludge pyrolysis device includes a cylinder body 11, a rotating shaft 3 is arranged at the center of the cylinder body 11, the two ends of the rotating shaft 3 are supported by the bearing housing 2, and the ends of the rotating shaft 3 are connected Material propulsion motor 1 is arranged. A spiral-shaped material propulsion piece 5 is fixed on the outside of the rotating shaft 3, and one end of the material propulsion piece 5 is connected to a feeding device 13, and a feeding air lock device 12 is provided between the feeding device 13 and the cylinder 11, The material can be fed into the cylinder body 11 through the feeding device 13 . An air release port 4 is fixed on the upper end of the cylinder body 11 opposite to the feeding device 13 , and a discharge pipe 15 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com