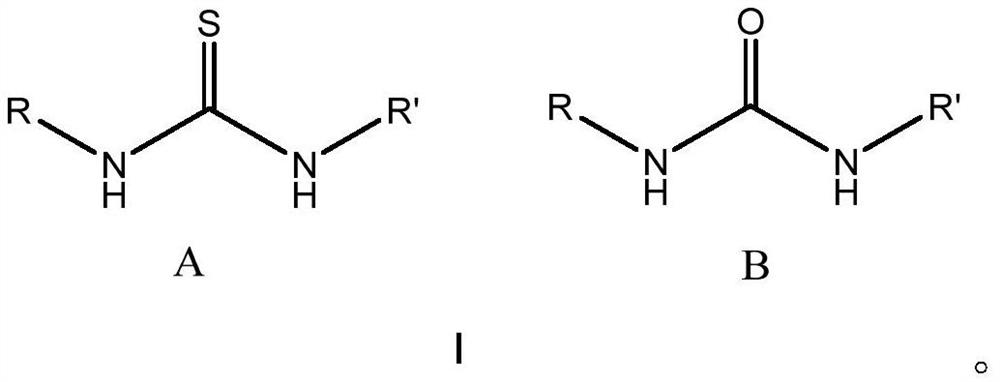

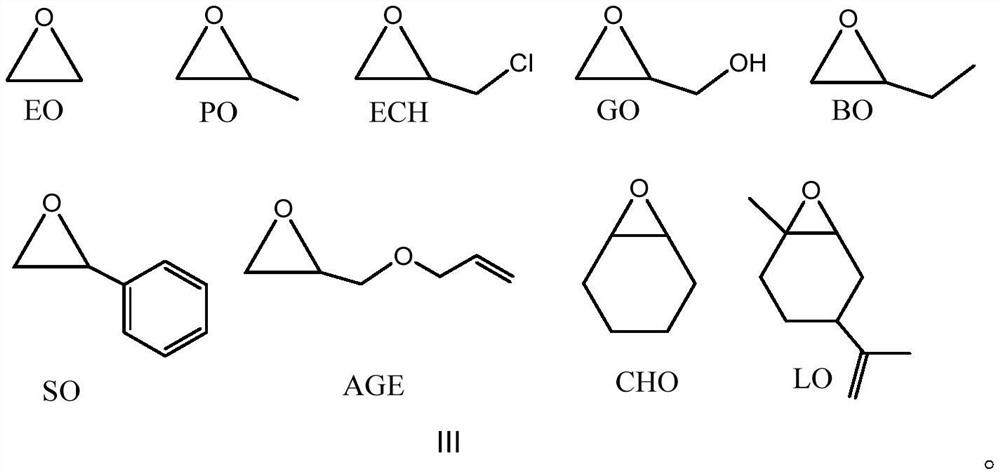

A method for preparing polyester by (thio)urea/organic base catalyzed ring-opening copolymerization of epoxide and cyclic anhydride

A technology for catalyzing rings and cyclic acid anhydrides with organic bases, applied in the field of polymer materials, can solve problems such as increasing production costs, and achieve the effects of reducing production costs, high activity and selectivity, and realizing industrialization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

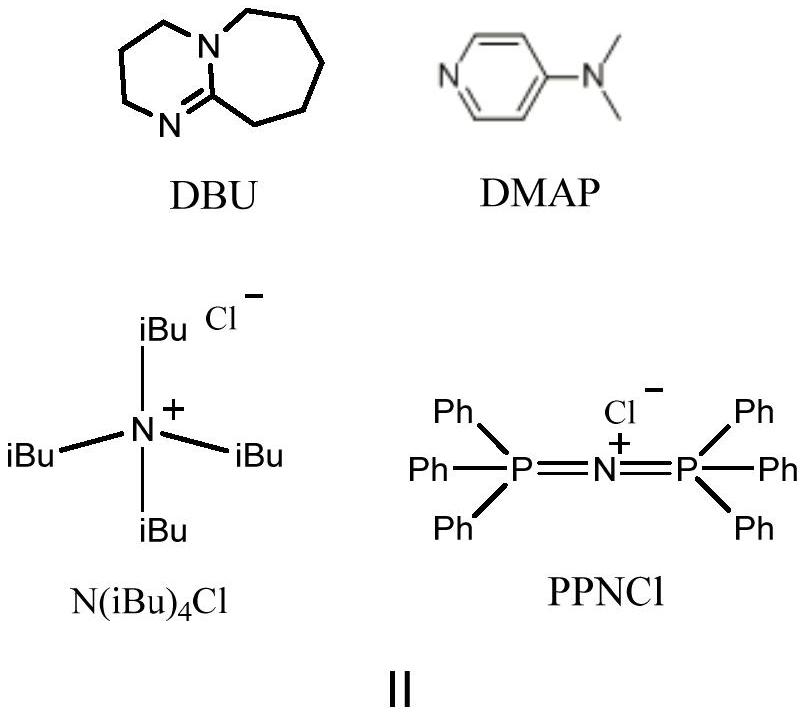

[0029] Embodiment 1, urea and DBU are used for the ring-opening copolymerization of CHO and PA

[0030] In an anhydrous and oxygen-free environment, add 0.05mmol urea, 0.05mmol DBU, 5mmol PA and 25mmol CHO to the flask in turn, stir evenly at room temperature, place it in a set 110°C constant temperature reaction bath for 20min, and take samples for NMR analysis . The product was dissolved in dichloromethane, and the polymer was obtained by precipitation with methanol, which was vacuum-dried by suction and then tested for molecular weight. PA conversion rate: 48%, polyester selectivity: 95%, monomer amount converted per unit catalyst per unit time (TOF): 144, molecular weight (Mn): 4.7KDa, molecular weight distribution: PDI=1.27.

Embodiment 2

[0031] Embodiment 2, urea and DBU and benzyl alcohol are used for the ring-opening copolymerization of CHO and PA

[0032] In an anhydrous and oxygen-free environment, add 0.05mmol urea, 0.05mmol DBU, 0.05mmol benzyl alcohol, 5mmol PA and 25mmol CHO to the flask in sequence, stir evenly at room temperature, and place it in a set 110°C constant temperature reaction bath for 20min. , sampled for NMR analysis. The product was dissolved in dichloromethane, and the polymer was obtained by precipitation with methanol, which was vacuum-dried by suction and then tested for molecular weight. PA conversion rate: 52%, polyester selectivity: 96%, monomer amount converted per unit catalyst unit time (TOF): 156, molecular weight (Mn): 2.9KDa, molecular weight distribution: PDI=1.25.

Embodiment 3

[0033] Embodiment 3, urea and DMAP are used for the ring-opening copolymerization of CHO and PA

[0034] In an anhydrous and oxygen-free environment, add 0.05mmol urea, 0.05mmol DMAP, 5mmol PA and 25mmol CHO to the flask in turn, stir evenly at room temperature, place it in a set 110°C constant temperature reaction bath for 40min, and take samples for NMR analysis . The product was dissolved in dichloromethane, and the polymer was obtained by precipitation with methanol, which was vacuum-dried by suction and then tested for molecular weight. PA conversion rate: 29%, polyester selectivity: 95%, monomer amount converted per unit catalyst per unit time (TOF): 44, molecular weight (Mn): 3.1KDa, molecular weight distribution: PDI=1.18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com