Preparation method for nanometer magnesium oxide ozone catalyst and advanced treatment method for catalytically oxidizing wastewater of coal chemical industry by using catalyst

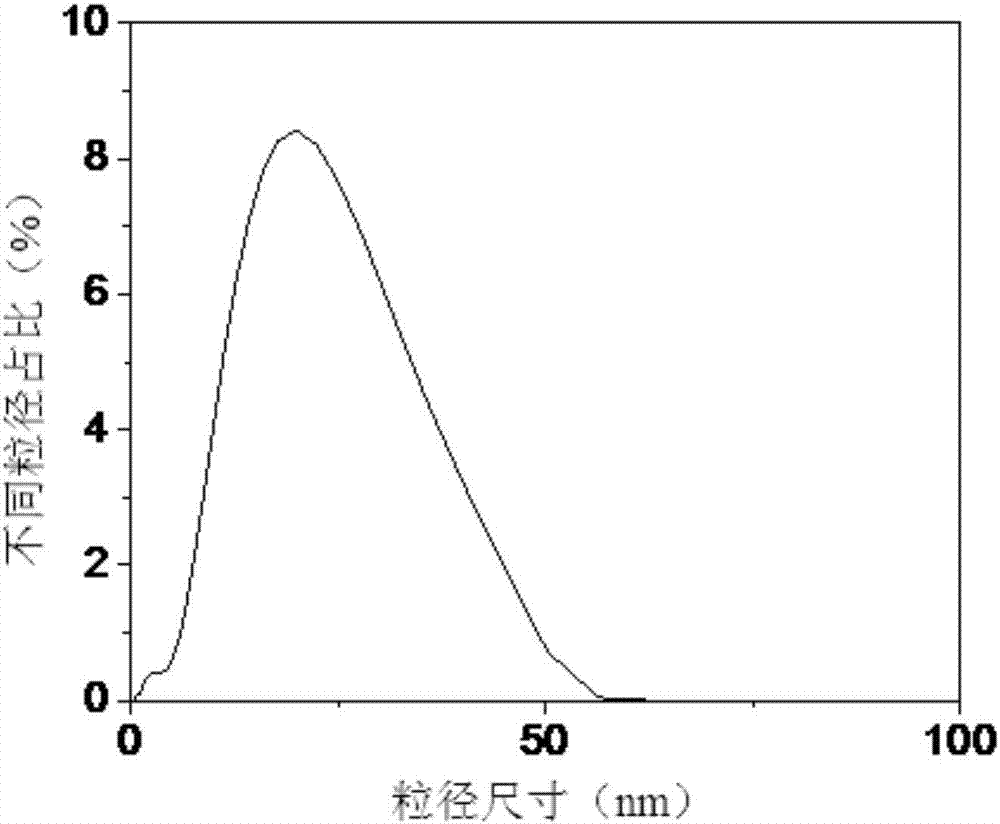

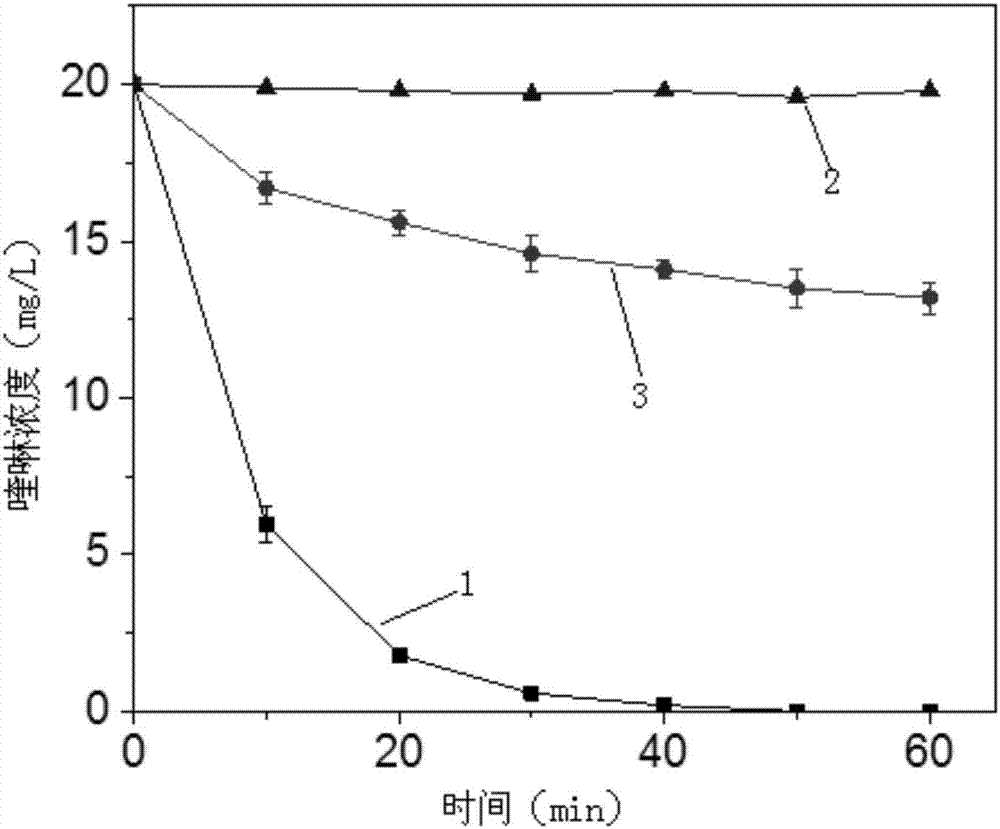

A nano-magnesium oxide, catalytic oxidation technology, applied in the direction of oxidized water/sewage treatment, physical/chemical process catalyst, water/sewage treatment, etc., can solve the secondary pollution metal oxide catalyst catalytic effect, homogeneous catalyst cannot be recycled and repeated Utilization, easy loss of active components and other issues, to achieve the effect of low magnesium ion dissolution, low toxicity, and small adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

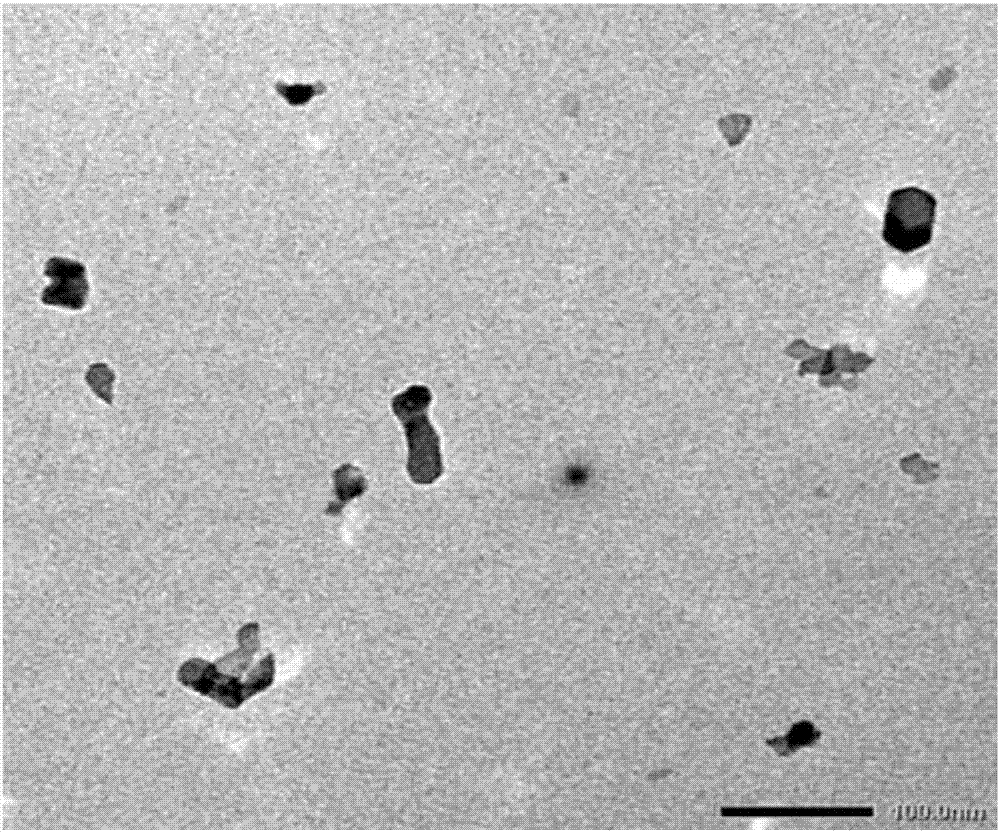

[0033] Specific embodiment one: the preparation method of a kind of nano magnesium oxide ozone catalyst of the present embodiment carries out according to the following steps:

[0034] 1. MgCl 2 Add it into water, stir to dissolve it, and prepare MgCl with a concentration of 0.05mol / L~0.15mol / L 2 solution;

[0035] Two, the concentration obtained in step one is the MgCl of 0.05mol / L~0.15mol / L 2 Add a dispersant to the solution, react at room temperature and a stirring speed of 150r / min to 250r / min, and the reaction time is 40min to 80min to obtain a mixture solution;

[0036] Dispersant described in step 2 and MgCl described in step 1 2 The mass ratio is 0.5~1.5:100;

[0037] 3. Add NaOH solution dropwise at a rate of 0.5mL / min to 1.5mL / min to the mixture solution obtained in step 2, and age for 20h to 24h;

[0038] The amount of the substance of NaOH in the NaOH solution described in step 3 and the MgCl described in step 1 2 The ratio of the amount of substance is 0.4~0...

specific Embodiment approach 2

[0042]Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, MgCl with a concentration of 0.1 mol / L is formulated 2 solution. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the dispersant in step 2 is polyvinyl alcohol. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com