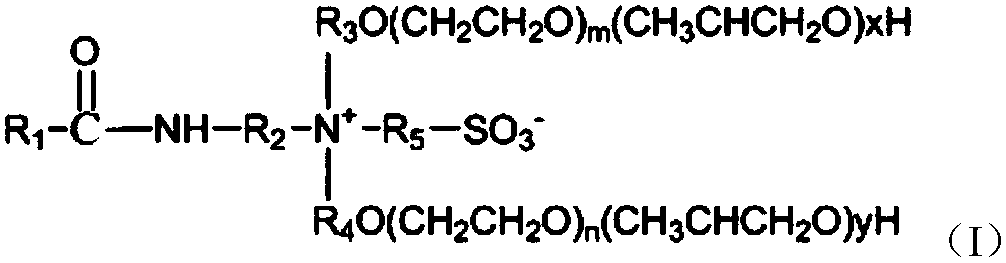

Oil displacing composition containing sulphobetaine type surfactant and preparation method and application thereof

A sulfobetaine-type surfactant technology, which is applied to oil displacement compositions containing sulfobetaine-type surfactants and its preparation and application fields, can solve problems such as injection difficulties and formation plugging, and achieve interfacial activity High, strong oil washing ability, simple system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

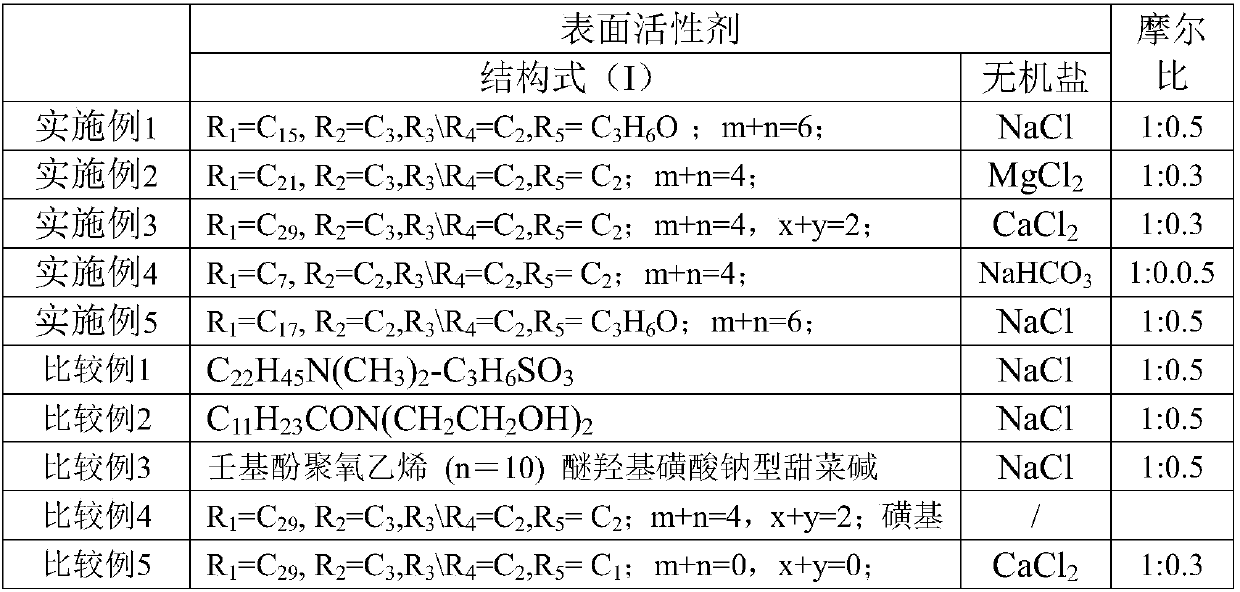

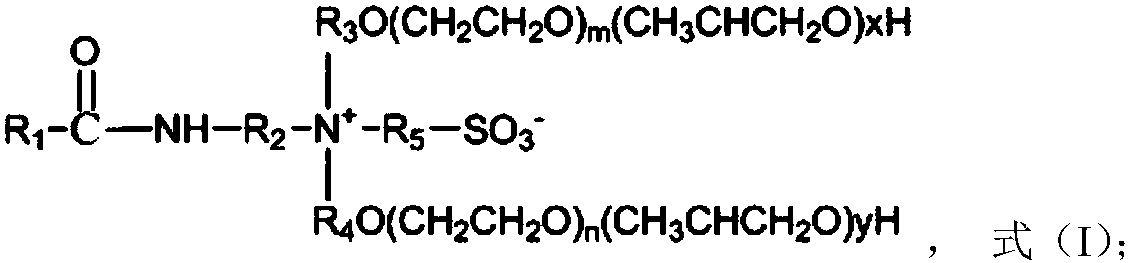

Embodiment 1

[0034] 1. Surfactant Preparation

[0035](1) palmitic acid amide sulfonate betaine surfactant (R 1 =C 15 , R 2 =C 2 , R 3 \R 4 =C 2 , R 5 =C 3 h 6 O) Preparation

[0036] a) Add long carbon chain hexadecanoic acid methyl ester and the required amount of amidation reagent N,N-bis(2-hydroxyethyl)ethylenediamine into the reaction kettle, react at 130°C for 6 hours, turn on the vacuum pump, and pump Remove excess N,N-bis(2-hydroxyethyl)ethylenediamine, and then heat to 150°C while passing nitrogen into the reactor equipped with condensing device and stirring device, add ethylene oxide after heating for 40 minutes alkanes (2 moles), the temperature was maintained at 150°C and the reaction was stirred for 1 hour. Cool down to 80°C, add barium hydroxide as a catalyst, heat to 140°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, and then use nitrogen to blow 4 times to remove the air in the system, and then adjust the reaction temperature of the system ...

Embodiment 2

[0048] 1. Surfactant Preparation

[0049] (1) Erucamide sultaine surfactant (R 1 =C 21 , R 2 =C 2 , R 3 \R 4 =C 2 , R 5 =C 2 ) preparation

[0050] a) Add methyl erucate and the required amount of amidation reagent N,N-bis(2-hydroxyethyl)ethylenediamine into the reaction kettle, react at 145°C for 7 hours, turn on the vacuum pump, and remove excess N , N-bis(2-hydroxyethyl)ethylenediamine to obtain the erucic acid acyl tertiary amide product, and then heat to 150°C while passing nitrogen into the reactor equipped with a condensation device and a stirring device, after heating for 40 minutes Ethylene oxide (2 moles) was added, and the temperature was maintained at 150° C. and the reaction was stirred for 1 hour. Cool down to 80°C, add barium hydroxide as a catalyst, heat to 140°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, and then use nitrogen to blow 4 times to remove the air in the system, and then adjust the reaction temperature of the syst...

Embodiment 3

[0055] 1. Surfactant Preparation

[0056] (1) triacic acid amide sulfobetaine surfactant (R 1 =C 29 , R 2 =C 3 , R 3 \R 4 =C 2 , R 5 =C 2 ) preparation

[0057] a) Add the long carbon chain triacic acid methyl ester and the required amount of amidating reagent N,N-bis(2-hydroxyethyl)propylenediamine into the reaction kettle, react at 150°C for 8 hours, turn on the vacuum pump, and pump Remove excess N,N-bis(2-hydroxyethyl)propylenediamine to obtain triacyl acyl tertiary amine product, and then heat to 150°C while blowing nitrogen into a reactor equipped with a condensing device and a stirring device After heating for 40 minutes, ethylene oxide (2 moles) was added, and the temperature was maintained at 150° C. and stirred for 1 hour. Cool down to 80°C, add barium hydroxide as a catalyst, heat to 140°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, and then use nitrogen to blow 4 times to remove the air in the system, and then adjust the reaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com