Subway shield segment

A shield segment and subway technology, which is applied in underground chambers, shaft linings, tunnel linings, etc., to achieve the effects of simple manufacture, dispersing stress concentration, and improving overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

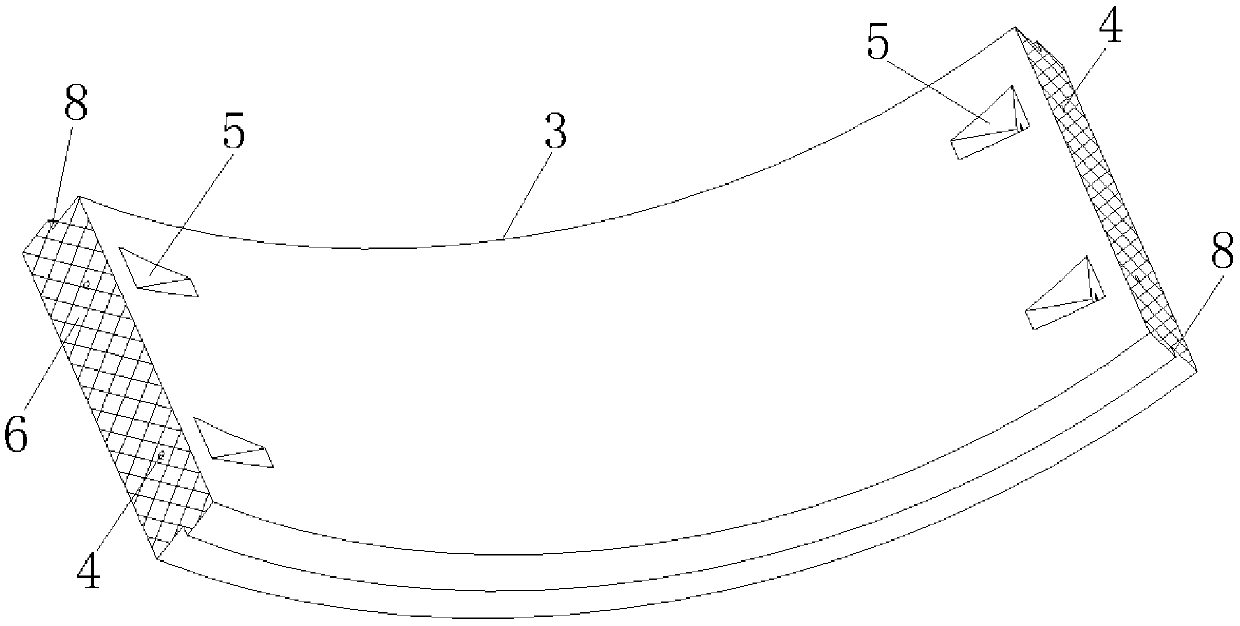

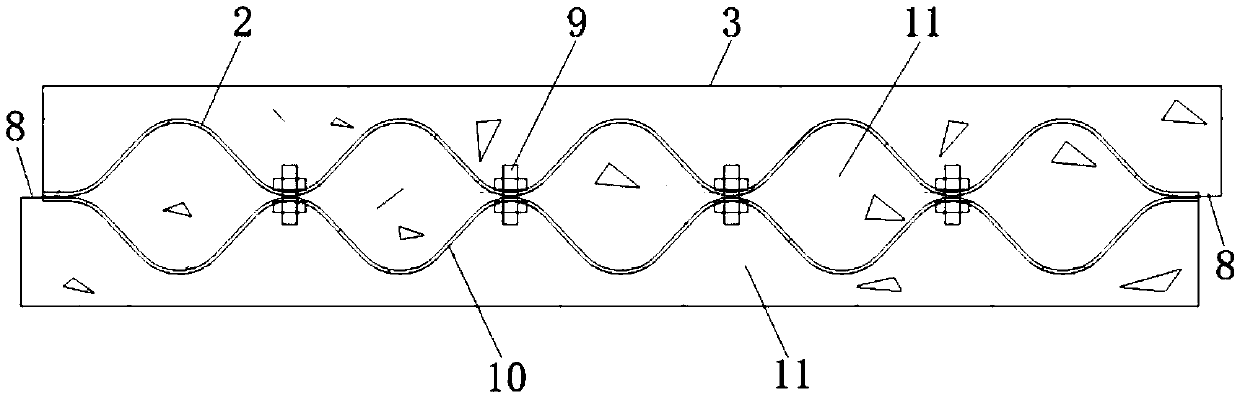

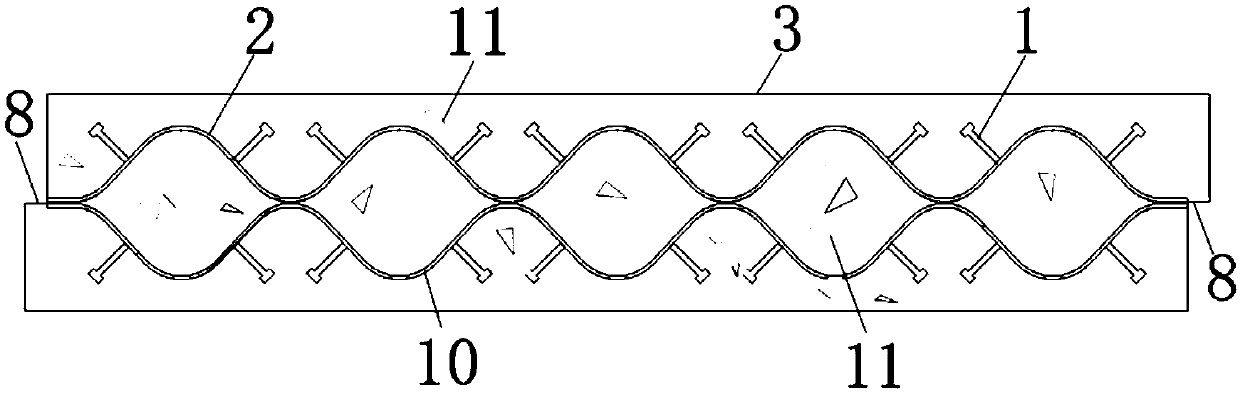

[0019] like figure 1 As shown, the shape of the subway shield segment of the present invention is an arc-shaped sheet whose radian is 1 / 5 circle. image 3 The shown interconnected inner corrugated steel plate 2 and outer corrugated steel plate 10 are used as a framework to form an arc-shaped sheet body 3 made of high-strength concrete 11 . The crests of the inner corrugated steel plate and the outer corrugated steel plate are fixedly connected by connecting bolts 9, and studs 1 are respectively welded on both sides of the troughs of the inner corrugated steel plate and the outer corrugated steel plate to better combine the corrugated steel plate with concrete. The two ends are respectively processed into a wave-free flat plate shape. When pouring concrete, use molds to pour the axial ends of the sheet into figure 1 and the "L"-shaped splicing groove 8 shown in Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com