Surface-modified colloidal ceria abrasive particles, preparation method therefor, and polishing slurry composition containing same

A cerium oxide and surface modification technology, which is applied in the direction of polishing compositions containing abrasives, chemical instruments and methods, cerium oxide/cerium hydroxide, etc., can solve the problem of fragility of film surface defects, rising unit price of polishing slurry, It is difficult to ensure the repeatability of manufacturing engineering and polishing engineering to achieve the effect of increasing specific surface area and increasing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

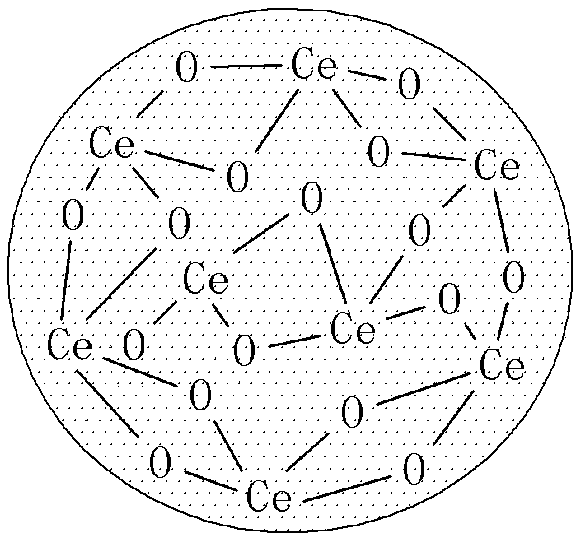

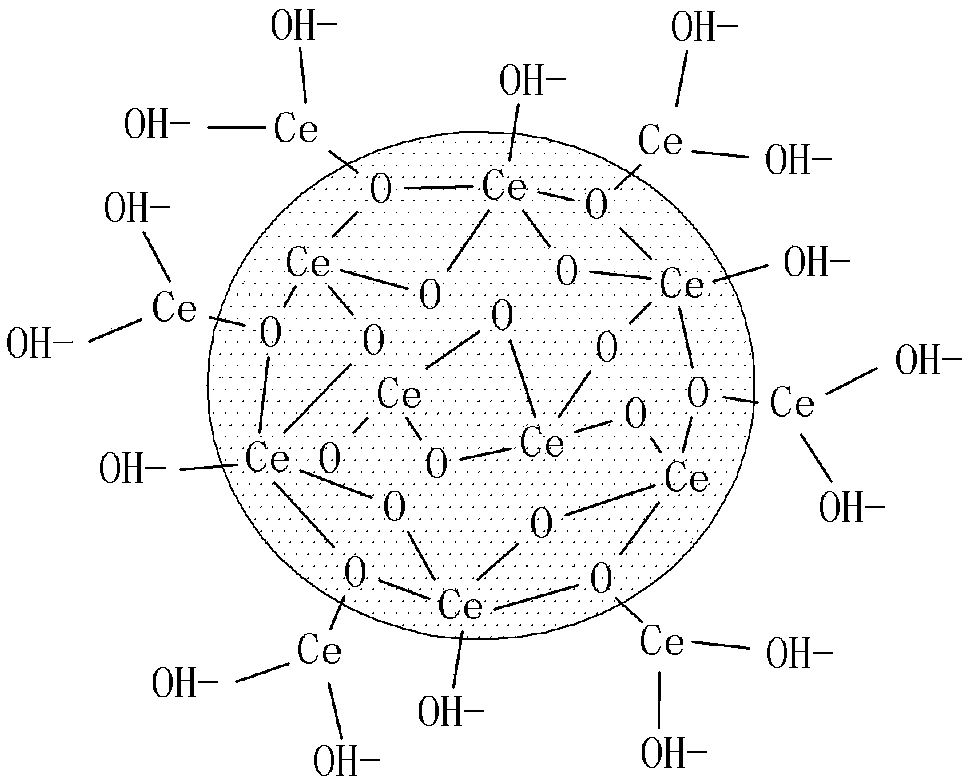

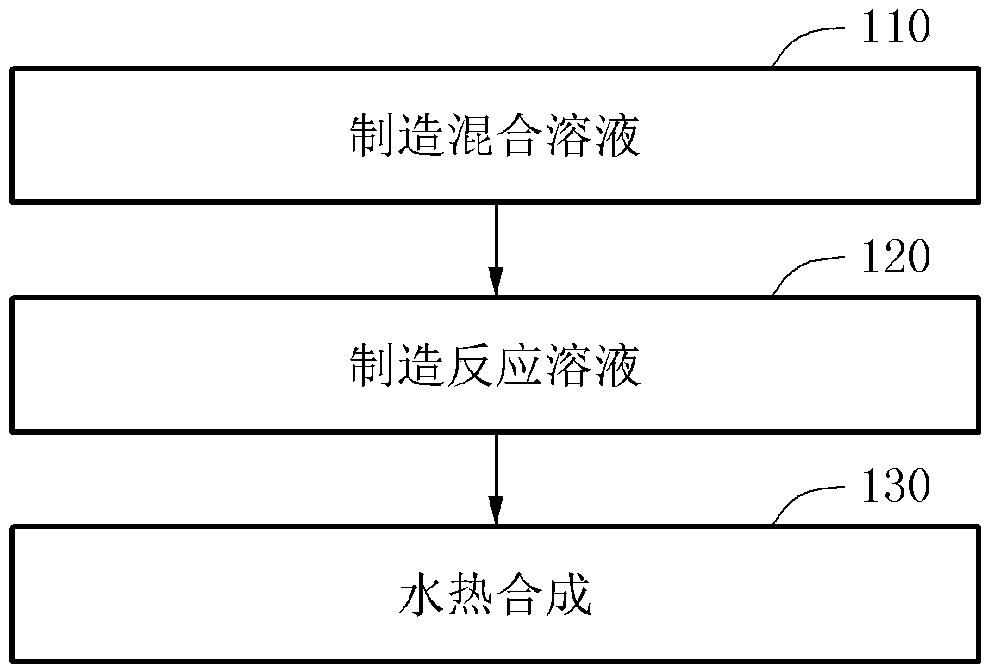

[0081] The colloidal ceria polishing particles of 60nm size as the polishing particles and the cerium ammonium nitrate as the cerium precursor are mixed with a weight ratio of 0.15 (colloidal ceria polishing particles / cerium precursor) and stirred at 70°C at a speed of 300rpm 1 hour. Next, ammonium hydroxide was added as a precipitant, and the mixture was stirred at 70 and 300 rpm for 1 hour to prepare a reaction solution with pH 10. Afterwards, the reaction solution was hydrothermally synthesized at a temperature of 250° C. and a pressure of 30 bar for 12 hours, and then washed with deionized water to produce surface-modified colloidal ceria polishing particles.

Embodiment 2

[0083] In Example 1, except that the weight ratio of colloidal ceria polishing particles / cerium precursor was 0.76, the surface-modified colloidal ceria polishing particles were produced in the same manner as in Example 1.

Embodiment 3

[0085] In Example 1, except that the weight ratio of colloidal ceria polishing particles / cerium precursor was 1.52, the surface-modified colloidal ceria polishing particles were produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com