Powder curing agent for expanded perlite thermal insulation plates, and preparation method thereof

A technology of expanded perlite and thermal insulation board, used in cement production and other directions, can solve the problem of powder curing agent being strong alkaline and easy to return to alkali, and achieve the effects of high strength, elimination of radioactive substances, and improvement of structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

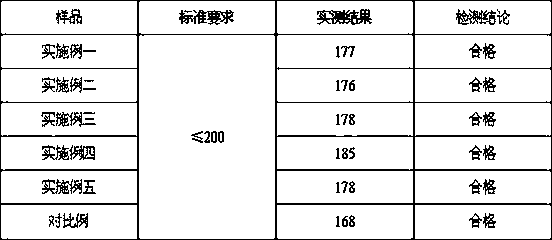

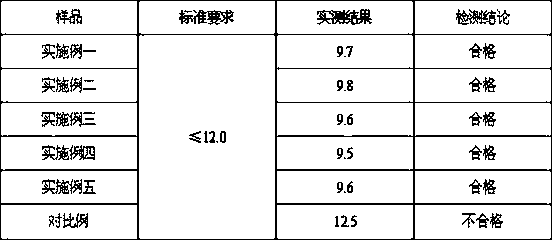

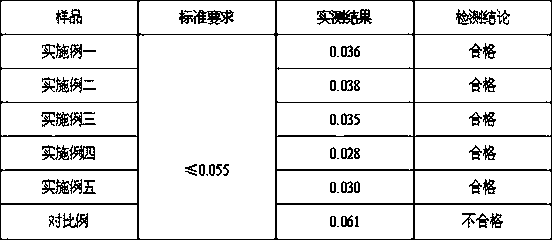

Examples

Embodiment 1

[0041] A preparation method for a powder curing agent for expanded perlite insulation boards, comprising the steps of:

[0042] (1) Ingredients: Weigh 500g of power generation chimney ash, 30g of industrial aluminum sulfate, 50g of activated silica, 250g of cement clinker powder, 80g of fluorspar powder and 5g of retarder;

[0043] (2) Drying: Dry 500g of power generation chimney ash at a high temperature of 600°C for 1 hour;

[0044] (3) Calcination: calcine 80g of fluorspar powder in a tubular heating furnace at a low temperature at 150°C for 2 hours;

[0045] (4) Mixing: Throw 500g of dried chimney ash into the mixer, and add 30g of industrial aluminum sulfate, 50g of active silica, 250g of cement clinker powder, 80g of fluorspar powder and 5g of retarder , carry out mixing and stirring for 30min and then discharge.

[0046] Select the Chinese patent application publication number CN105948638A, remove the fly ash, quicklime, diatomaceous earth, and sodium silicate as the ...

Embodiment 2

[0048] A preparation method for a powder curing agent for expanded perlite insulation boards, comprising the steps of:

[0049] (1) Ingredients: Weigh 530g of power generation chimney ash, 30g of industrial aluminum sulfate, 60g of activated silica, 275g of cement clinker powder, 90g of fluorspar powder and 6g of retarder;

[0050] (2) Drying: Dry 530g of power generation chimney ash at a high temperature of 600°C for 1 hour;

[0051] (3) Calcination: 90g of fluorspar powder was calcined in a tubular heating furnace at a low temperature, the temperature was set at 150°C, and the time was 2h;

[0052] (4) Mixing: Throw 530g of dried chimney ash into the mixer, and add 30g of industrial aluminum sulfate, 60g of active silica, 275g of cement clinker powder, 90g of fluorspar powder and 6g of retarder , carry out mixing and stirring for 30min and then discharge.

[0053] Select the Chinese patent with the application publication number CN105948638A, remove the fly ash, quicklime,...

Embodiment 3

[0055] A preparation method for a powder curing agent for expanded perlite insulation boards, comprising the steps of:

[0056] (1) Ingredients: Weigh 550g of power generation chimney ash, 60g of industrial aluminum sulfate, 60g of activated silica, 300g of cement clinker powder, 100g of fluorspar powder and 6g of setting retarder;

[0057] (2) Drying: Dry 550g of power generation chimney ash at a high temperature of 600°C for 1 hour;

[0058] (3) Calcination: Calcining 100g of fluorspar powder in a tubular heating furnace at a temperature of 150°C for 2 hours;

[0059] (4) Mixing: Throw 550g of dried chimney ash into the mixer, and add 60g of industrial aluminum sulfate, 60g of active silica, 300g of cement clinker powder, 100g of fluorspar powder and 6g of setting retarder in sequence , carry out mixing and stirring for 30min and then discharge.

[0060] Select the Chinese patent with the application publication number CN105948638A, remove the fly ash, quicklime, diatomace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com