Green environment-friendly aluminum silver paste

A green, environmentally friendly, aluminum-silver paste technology, applied in the field of aluminum pigments, can solve the problems of difficult to disperse water-based paint, unsuitable, unsuitable for water-based paint, etc., and achieve the effect of simple preparation method and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A green environment-friendly aluminum silver paste is characterized in that the preparation process is as follows:

[0023] (1) To prepare a coupling agent, mix methyltrimethoxysilane, titanate and aminopropylmethyldimethoxysilane at a mass ratio of 1:4:3, and mix for 40 minutes to obtain a coupling agent;

[0024] (2) To prepare the auxiliary agent, mix xylene, ethyl acetate and catechol according to the mass ratio of 2:3:5, and the mixing time is 30 minutes to obtain the auxiliary agent;

[0025] (3) Weigh raw materials: Weigh aluminum powder, stearic acid, coupling agent, additives, and solvent oil as raw materials according to the required number of parts;

[0026] (4) Add 60 parts of aluminum powder, 0.4 parts of stearic acid, 0.3 parts of coupling agent, 1 part of auxiliary agent and 100 parts of solvent oil into the ball mill for 18 hours to make flake particles;

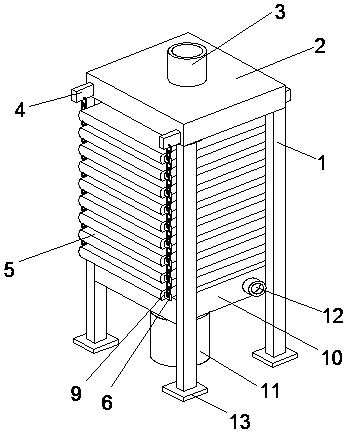

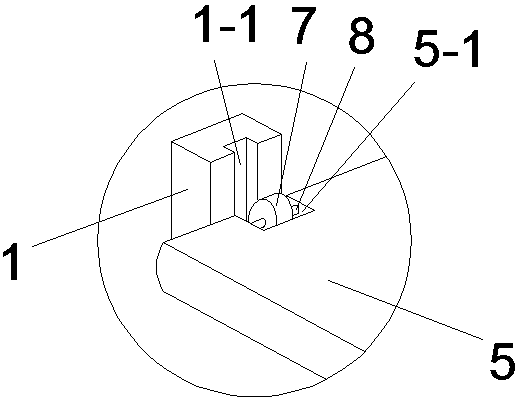

[0027] (5) Put the flaky particles prepared in step (4) into a sieving device for sieving, and th...

Embodiment 2

[0044] With a kind of green environment-friendly aluminum-silver paste described in embodiment one, its difference is:

[0045] (1) To prepare a coupling agent, mix methyltrimethoxysilane, titanate and aminopropylmethyldimethoxysilane at a mass ratio of 1:4:3, and mix for 40 minutes to obtain a coupling agent;

[0046] (2) To prepare the auxiliary agent, mix xylene, ethyl acetate and catechol according to the mass ratio of 2:3:5, and the mixing time is 30 minutes to obtain the auxiliary agent;

[0047] (3) Weigh raw materials: Weigh aluminum powder, stearic acid, coupling agent, additives, and solvent oil as raw materials according to the required number of parts;

[0048] (4) Add 90 parts of aluminum powder, 0.45 parts of stearic acid, 0.3 parts of coupling agent, 1.2 parts of additives and 100 parts of solvent oil into a ball mill for ball milling for 20 hours to make flaky particles;

[0049] (5) Put the flaky particles prepared in step (4) into a sieving device for sievi...

Embodiment 3

[0054] With a kind of green environment-friendly aluminum-silver paste described in embodiment one, its difference is:

[0055] (1) To prepare a coupling agent, mix methyltrimethoxysilane, titanate and aminopropylmethyldimethoxysilane at a mass ratio of 1:4:3, and mix for 45 minutes to obtain a coupling agent;

[0056] (2) To prepare the auxiliary agent, mix xylene, ethyl acetate and catechol according to the mass ratio of 2:3:5, and the mixing time is 55 minutes to obtain the auxiliary agent;

[0057] (3) Weigh raw materials: Weigh aluminum powder, stearic acid, coupling agent, additives, and solvent oil as raw materials according to the required number of parts;

[0058](4) Add 100 parts of aluminum powder, 0.5 parts of stearic acid, 0.3 parts of coupling agent, 1 part of auxiliary agent and 100 parts of solvent oil into a ball mill for ball milling for 19 hours to make flaky particles;

[0059] (5) Put the flaky particles prepared in step (4) into a sieving device for sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com