Device for measuring gas transmission rate of thin film according to resistivity method and manufacturing and testing method thereof

A technology of gas transmission rate and electrical resistance method, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of high background noise value, achieve low background noise value, less molecular adsorption, The effect of small total area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

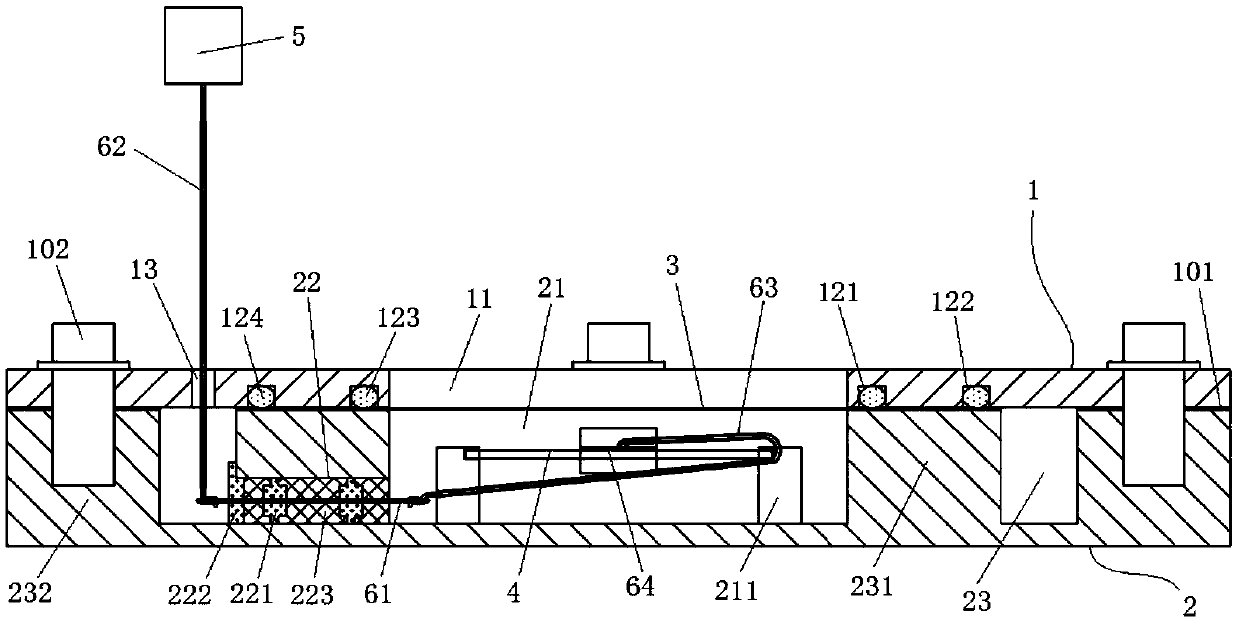

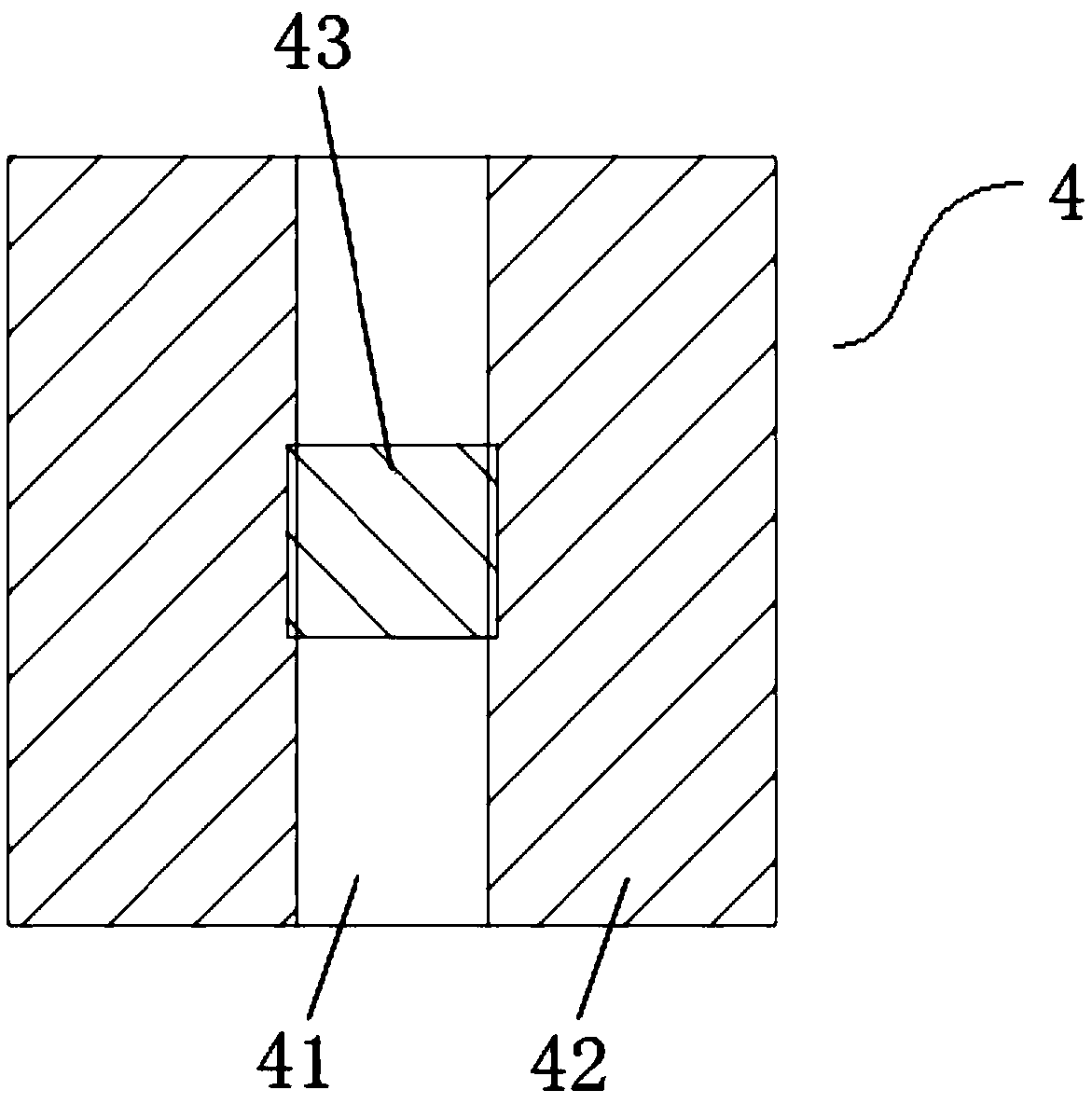

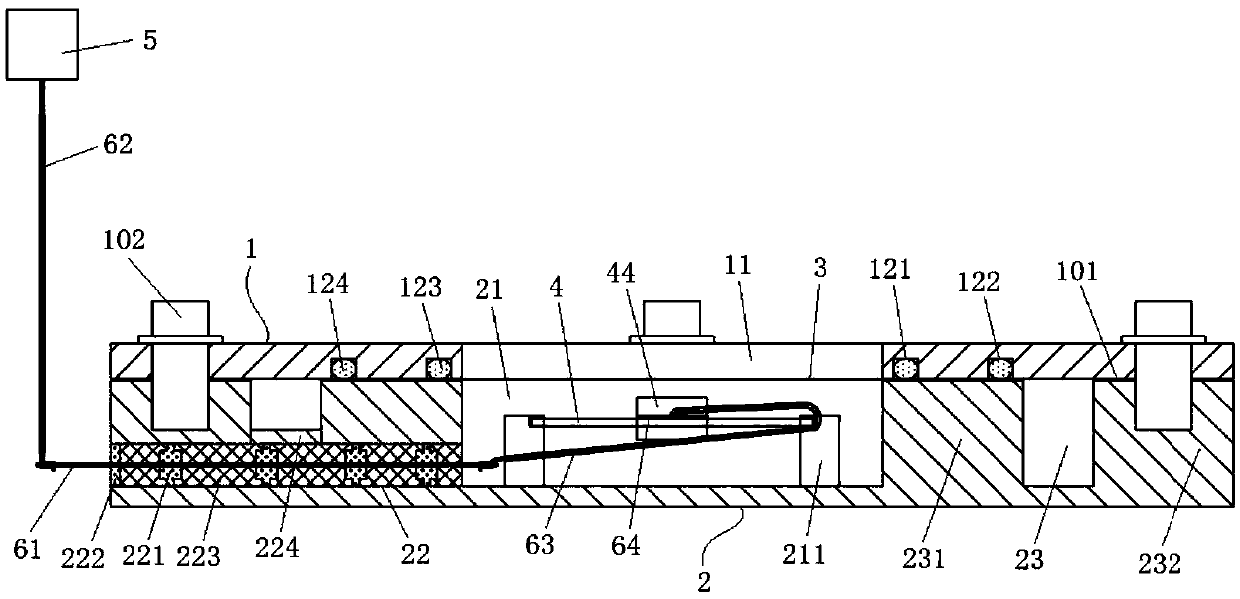

[0063] A device for testing the gas permeability of thin films by resistance method in this embodiment is as follows: figure 1 shown. A chamber 21 is provided in the lower cavity 2, and a lead hole 22 for the hard wire 61 to pass is provided on the side wall of the chamber 21. After the hard wire 61 passes through the lead hole 22, the lead hole 22 is made of glass or ceramic material gas. The airtight potting body 223 is potted. There is a resistance detection sample piece 4 in the chamber 21 ; the hard wire 61 is connected to the second soft wire 63 with an insulating layer in the chamber 21 , and is connected to the lead-out electrode 42 of the active metal 43 through the electrode patch 64 . The hard wire 61 is connected to the first flexible wire 62 with an insulating layer in the surrounding chamber 23 , and the lead-out testing device is connected to the resistance measuring meter 5 . The upper cover body 1 is provided with a hole 11 corresponding to the position of t...

Embodiment 2

[0075] In this embodiment, the thin film 3 is made of aluminum foil (Mocon Co., USA), and the permeation amount in the Z direction is zero, so the damage of the active metal is entirely due to the edge permeation in the XY direction. Here, the actual sealing effect of the test device will be described in combination with experimental data. The better the sealing effect is, the more difficult it is for the active metal to be damaged by external water and oxygen to maintain a stable resistance value. On the contrary, the active metal is damaged and the resistance increases until it is insulated.

[0076] The device components used for the test were vacuum-dried at 80°C for 12 hours, and then transferred to a glove box. The water and oxygen content of the glove box was kept below 0.01ppm. The resistance detection sample piece 4 with the ITO lead-out electrode 42 is placed on the mask plate, and a layer of metallic calcium is vapor-deposited under high vacuum conditions in the PVD...

Embodiment 3

[0088] As mentioned earlier, film 3 uses aluminum foil, which has zero penetration in the Z direction, and the damage to the active metal is entirely due to edge penetration in the XY direction. Because aluminum foil can completely block water and oxygen molecules in the Z direction, it is used for the independent zero value (individual zero) collection of Mocon water permeability test equipment, that is, there is no transmission in the direction of the cavity, and machine noise is collected. The purpose of using this aluminum foil in this embodiment is to understand the edge sealing effect and determine the background noise value of the test device.

[0089] The preferred sealing structure that provides according to embodiment 2 assembles inner seal ring 123, outer seal ring 124, sealant 101, places film 3, surrounds chamber 23 and fills absorbent (8Fe / 2P 2 o 5 ); take out the test device from the glove box, place it in an air environment for testing (25° C., 65% RH), and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com