Friction nano-generator based wind power generation integrated system

A nano-generator and integrated system technology, applied in friction generators, battery circuit devices, current collectors, etc., can solve the problems of large footprint, remote distribution of wind power towers, increased transportation costs and land occupation costs, and achieve The effect of strong structural adaptability, sensitive wind speed sensing, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

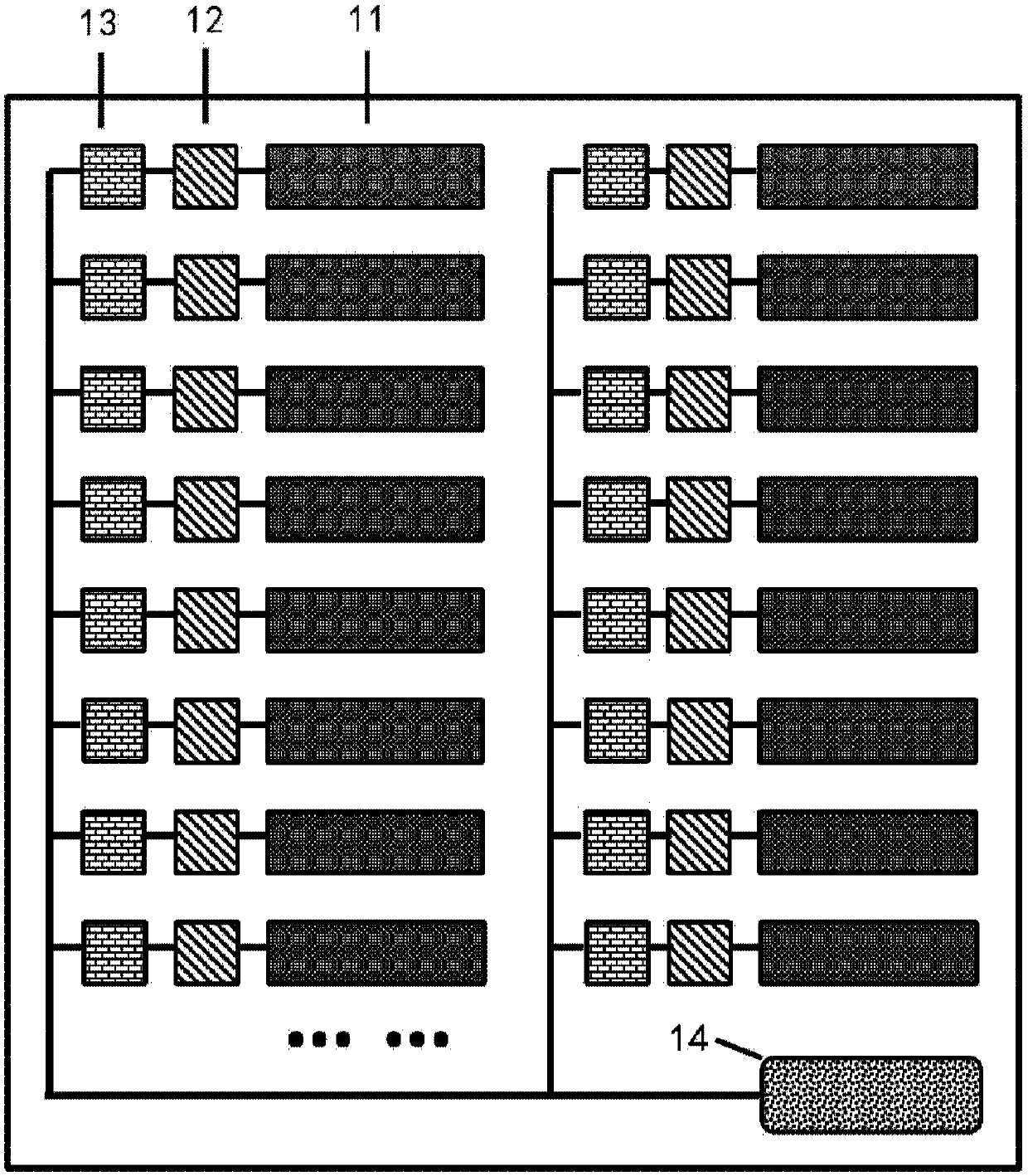

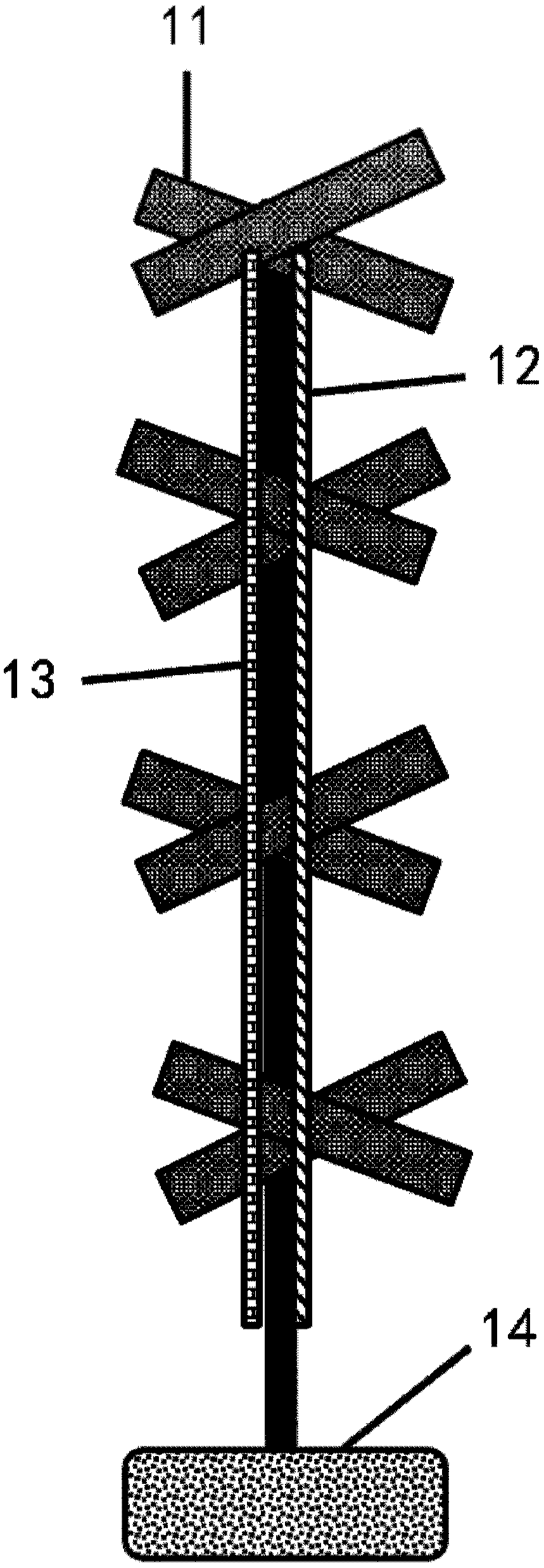

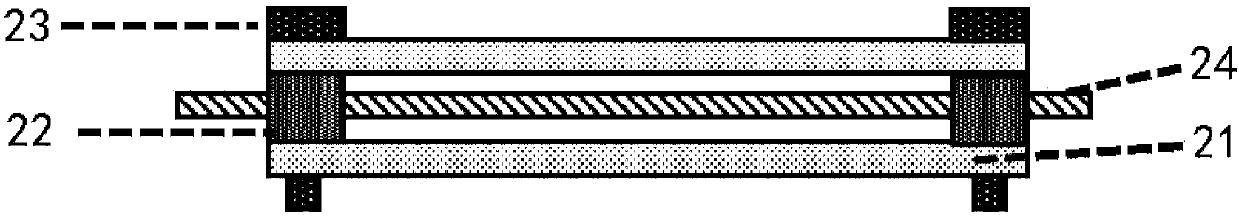

[0033] The present disclosure provides an integrated wind power generation system based on frictional nanogenerators. The integration is realized by arranging the frictional nanogenerators in parallel or at intervals along the support rods, and connecting them with transformers and management circuits to output Stable constant voltage signal and pulse current signal, and the obtained stable signal is stored in the energy storage element, with high power generation efficiency, sensitive wind speed sensing, simple production, small size and strong structural adaptability, and can be used as an alternative to wind power towers .

[0034] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0035] In a first exemplary embodiment of the present disclosure, an integrated wind power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com