A kind of method and application of sun-cured tobacco absolute prepared by floating oil method

A smoke cleaning and oil floating technology, applied in the field of tobacco flavors and fragrances, can solve the problems of not being able to extract the aroma components of tobacco to the greatest extent, high equipment requirements, and difficulty in application, and achieve rich types, low cost, and full aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

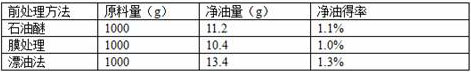

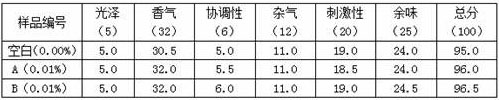

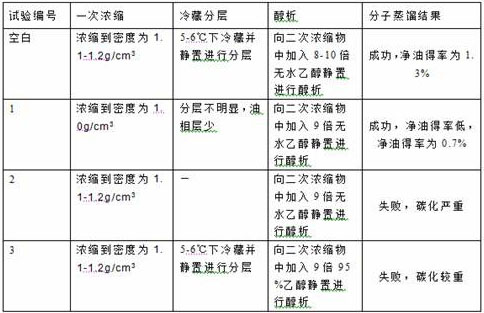

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing sun-cured tobacco absolute by floating oil method, comprising the steps of:

[0047] Step (1), extraction: reflux extraction is performed on the sun-cured tobacco leaves, and the filtrate is filtered to obtain the extract;

[0048] Step (2), concentration: Concentrate the extract obtained in step (1) at a temperature of 65°C to a density of 1.15g / cm 3 , to obtain a concentrated solution;

[0049] Step (3), refrigerating and stratifying: refrigerating the concentrated solution obtained in step (2) for stratification to obtain the upper oily substance and the lower water-soluble substance;

[0050] Step (4), secondary concentration, alcohol analysis and filtration: at a temperature of 68°C, vacuum-concentrate the upper oily substance obtained in step (3) to obtain a secondary concentrate; add absolute ethanol to the secondary concentrate Carry out alcohol analysis, after no more precipitates are separated out, filter and remove the precipitates to...

Embodiment 2

[0056] A method for preparing sun-cured tobacco absolute by floating oil method, comprising the steps of:

[0057] Step (1), extraction: reflux extraction is performed on the sun-cured tobacco leaves, and the filtrate is filtered to obtain the extract;

[0058] Step (2), concentration: Concentrate the extract obtained in step (1) at a temperature of 60°C to a density of 1.1g / cm 3 , to obtain a concentrated solution;

[0059] Step (3), refrigerating and stratifying: refrigerating the concentrated solution obtained in step (2) for stratification to obtain the upper oily substance and the lower water-soluble substance;

[0060] Step (4), secondary concentration, alcohol analysis and filtration: at a temperature of 60°C, vacuum-concentrate the upper oily substance obtained in step (3) to obtain a secondary concentrate; add absolute ethanol to the secondary concentrate Carry out alcohol analysis, after no more precipitates are separated out, filter and remove the precipitates to ...

Embodiment 3

[0073] A method for preparing sun-cured tobacco absolute by floating oil method, comprising the steps of:

[0074] Step (1), extraction: reflux extraction is performed on the sun-cured tobacco leaves, and the filtrate is filtered to obtain the extract;

[0075] Step (2), concentration: Concentrate the extract obtained in step (1) at a temperature of 70°C to a density of 1.2g / cm 3 , to obtain a concentrated solution;

[0076] Step (3), refrigerating and stratifying: refrigerating the concentrated solution obtained in step (2) for stratification to obtain the upper oily substance and the lower water-soluble substance;

[0077] Step (4), secondary concentration, alcohol analysis and filtration: at a temperature of 70°C, vacuum-concentrate the upper oily substance obtained in step (3) to obtain a secondary concentrate; add absolute ethanol to the secondary concentrate Carry out alcohol analysis, after no more precipitates are separated out, filter and remove the precipitates to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com