Composite photocatalyst and preparation method thereof

A composite catalyst and catalyst technology, applied in the field of photocatalysis, can solve the problems of low activity and expensive precious metal cocatalysts, and achieve the effects of easy availability of raw materials, simple preparation method, and improvement of photocatalytic hydrogen production activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

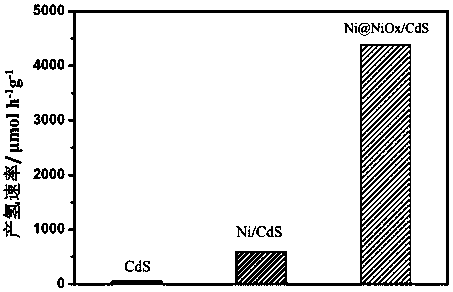

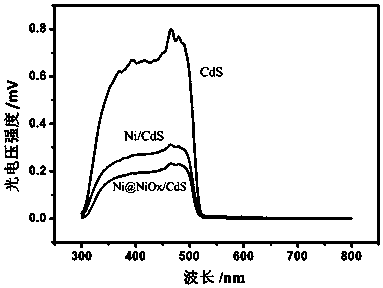

[0018] This embodiment provides a Ni@NiOx / CdS composite photocatalyst, the preparation method is as follows:

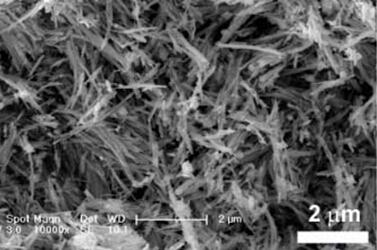

[0019] (1) Dissolve 4.66 g of cadmium nitrate tetrahydrate and 3.45 g of thiourea in 72 mL of ethylenediamine solution at room temperature, then react the resulting solution at 160°C for 48 h to obtain a precipitate, which is washed and dried That is, the CdS nanowires with ethylenediamine adsorbed on the surface were obtained.

[0020] (2) The above-mentioned obtained CdS nanowires and nickel acetylacetonate are dissolved in N,N-dimethylformamide solution, wherein the CdS nanowires, nickel acetylacetonate and N,N-dimethylformamide The mass ratio was 1:1:566.7; then the resulting solution was reacted at 200°C for 10 h; washed and dried under vacuum to obtain a Ni / CdS composite photocatalyst.

[0021] (3) The obtained Ni / CdS composite photocatalyst was calcined at 250 °C for 1 h to obtain Ni@NiOx / CdS composite photocatalyst with Ni@NiOx as CdS cocatalyst.

[0022] f...

Embodiment approach 2

[0024] This embodiment provides a Ni@NiOx / CdS composite photocatalyst, the preparation method is as follows:

[0025] (1) The preparation method of CdS nanowires is exactly the same as Embodiment 1.

[0026] (2) Dissolve the above-mentioned CdS nanowires and nickel acetylacetonate in N,N-dimethylformamide solution, wherein the CdS nanowires, nickel acetylacetonate and N,N-dimethylformamide The mass ratio was 0.9:1.1:566.7; then the resulting solution was reacted at 190 °C for 8 h; washed and dried under vacuum to obtain a Ni / CdS composite photocatalyst.

[0027] (3) The obtained Ni / CdS composite catalyst was calcined at 200 °C for 0.5 h to obtain Ni@NiOx / CdS composite photocatalyst with Ni@NiOx as CdS cocatalyst.

Embodiment approach 3

[0029] This embodiment provides a Ni@NiOx / CdS composite photocatalyst, the preparation method is as follows:

[0030] (1) The preparation method of CdS nanowires is exactly the same as Embodiment 1.

[0031] (2) The above-mentioned obtained CdS nanowires and nickel acetylacetonate are dissolved in N,N-dimethylformamide solution, wherein the CdS nanowires, nickel acetylacetonate and N,N-dimethylformamide The mass ratio was 1.1:0.9:566.7; then the resulting solution was reacted at 210 °C for 12 h; washed and dried under vacuum to obtain a Ni / CdS composite photocatalyst.

[0032] (3) The obtained Ni / CdS composite photocatalyst was calcined at 280 °C for 4 h to obtain Ni@NiOx / CdS composite photocatalyst with Ni@NiOx as CdS cocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com