a mo doping moo 3 @znin 2 the s 4 Z system photocatalyst and its preparation method and application

A photocatalyst and system technology, which can be used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of hindered kinetic process of hydrogen production, etc., and achieve ultra-high photocatalytic water splitting performance for hydrogen production, The effect of reducing hydrogen production overpotential and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation process of the present invention is as follows:

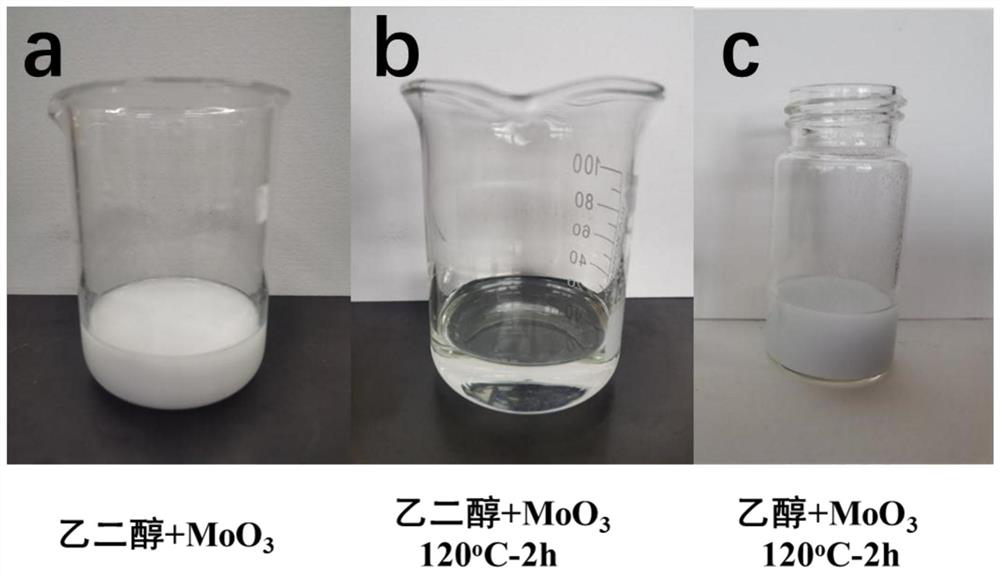

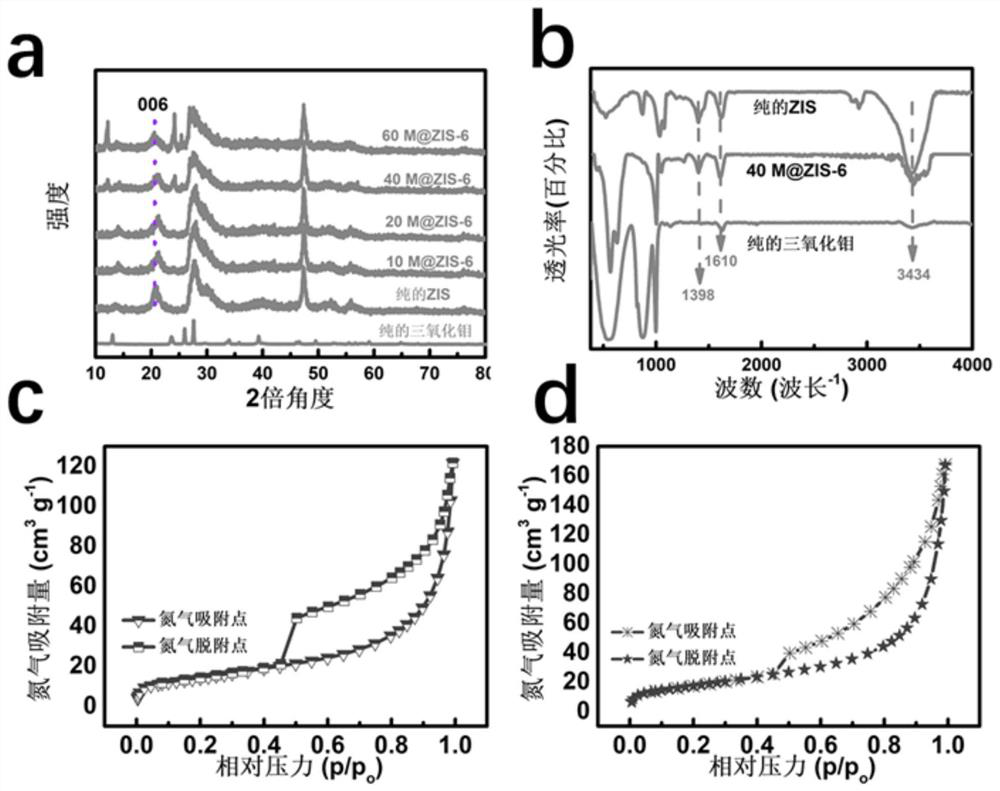

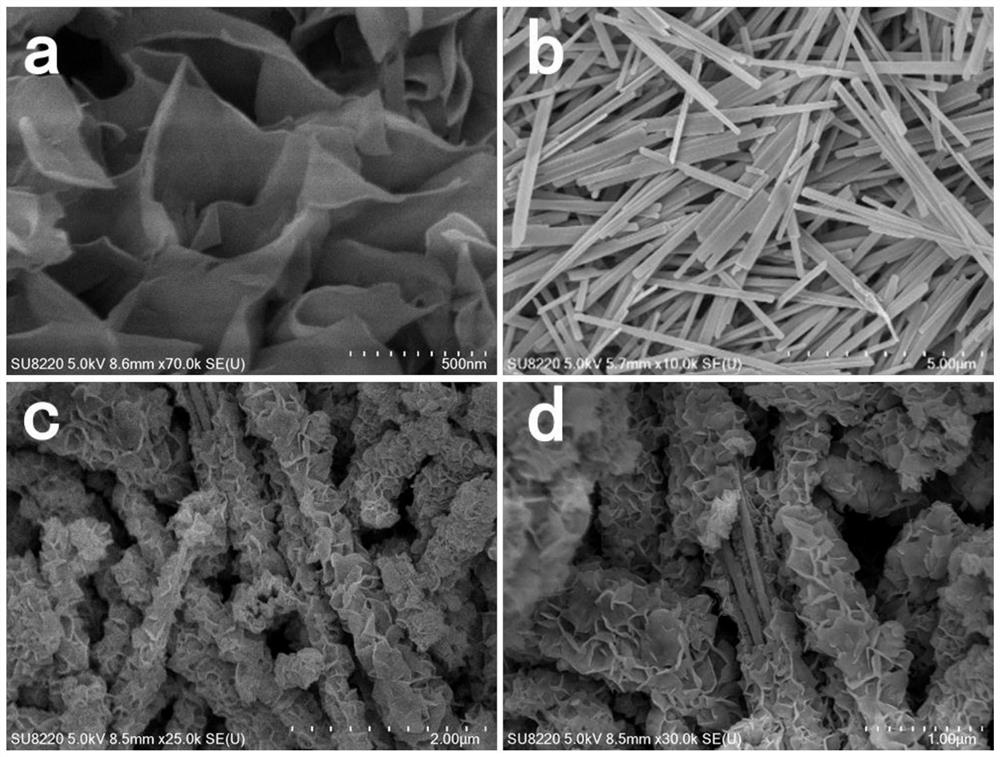

[0043] Synthesis of MoO via a hydrothermal process 3 nanorods, the MoO 3 Add nanorods (10-60mg) into 20ml of ethylene glycol solvent and sonicate for 30min, then dissolve zinc source, indium chloride tetrahydrate, and thioacetamide in the above ethylene glycol solution at a mass ratio of 136mg: 586mg: 300mg , stirred evenly for 30 minutes and transferred to a high-pressure reactor, kept at 120°C for 2-12 hours, cooled to room temperature naturally, the obtained product was washed with absolute ethanol, and vacuum-dried to obtain MoO doped with different Mo 3 @ZnIn 2 S 4 The Z system photocatalyst is named x-M@ZIS-y (x: the amount of molybdenum oxide added; y: the reaction time).

Embodiment 1

[0049] Dissolve 1.4g of ammonium molybdate tetrahydrate in 40mL of acid solution (33mL of water + 7mL of concentrated nitric acid), stir evenly, transfer to a high-pressure reactor, keep warm at 180°C for 24h, and naturally cool to room temperature. and absolute ethanol were washed three times each, and MoO was obtained after vacuum drying. 3 Nano stave. 10mg MoO 3 Disperse the nanorods in 20mL of ethylene glycol and sonicate for 30min; dissolve anhydrous zinc chloride, indium chloride tetrahydrate, and thioacetamide in the above ethylene glycol solution at a mass ratio of 136mg: 586mg: 300mg, and stir well 30min and transferred to an autoclave, kept at 120°C for 2h, cooled to room temperature naturally, the product obtained was centrifuged and washed three times with absolute ethanol, and dried in vacuum to obtain Mo-doped MoO 3 @ZnIn 2 S 4 Z system photocatalyst named 10-M@ZIS-2.

Embodiment 2

[0051] Dissolve 1.4g of ammonium molybdate tetrahydrate in 40mL of acid solution (33mL of water + 7mL of concentrated nitric acid), stir evenly, transfer to a high-pressure reactor, keep warm at 180°C for 24h, and naturally cool to room temperature. and absolute ethanol were washed three times each, and MoO was obtained after vacuum drying. 3 Nano stave. 20mg MoO 3 Disperse the nanorods in 20mL of ethylene glycol and sonicate for 30min, dissolve anhydrous zinc chloride, indium chloride tetrahydrate, and thioacetamide in the above ethylene glycol solution at a mass ratio of 136mg: 586mg: 300mg, and stir evenly 30min and transferred to an autoclave, kept at 120°C for 2h, cooled to room temperature naturally, washed three times with absolute ethanol, and dried in vacuum to obtain Mo-doped MoO 3 @ZnIn 2 S 4 Z system photocatalyst named 20-M@ZIS-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com