Carbon fiber hand plate and preparation method thereof

A carbon fiber and carbon fiber prepreg technology, applied in the field of carbon fiber prototype and its preparation, can solve the problems of poor dimensional accuracy controllability of carbon fiber prototype, long product development cycle, high time cost, high precision controllability and stability, shortening The effect of development cycle, saving tooling cost and time cost of designing and manufacturing tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing a carbon fiber prototype, comprising:

[0043] The carbon fiber block or high temperature resistant plastic block is processed by CNC to obtain the prototype blank;

[0044] The surface of the hand blank is reinforced with carbon fiber material.

[0045] Preferably, the high-temperature-resistant plastic blocks can be commercially available polyphenylene sulfide (PPS) blocks, polyetheretherketone (PEEK) blocks, fiber-added polybutylene terephthalate (fiber-added PBT ) block or nylon plus fiber block.

[0046] Preferably, the carbon fiber block is prepared by the following method:

[0047](1) According to the design requirements of the mechanical structure, a number of carbon fiber prepregs of the same specification obtained by cutting are laid layer by layer, and then several layers of carbon fiber prepregs that have been laid layer by layer are subjected to pressure treatment by a cold press , to obtain a preformed body.

[0048] It should be...

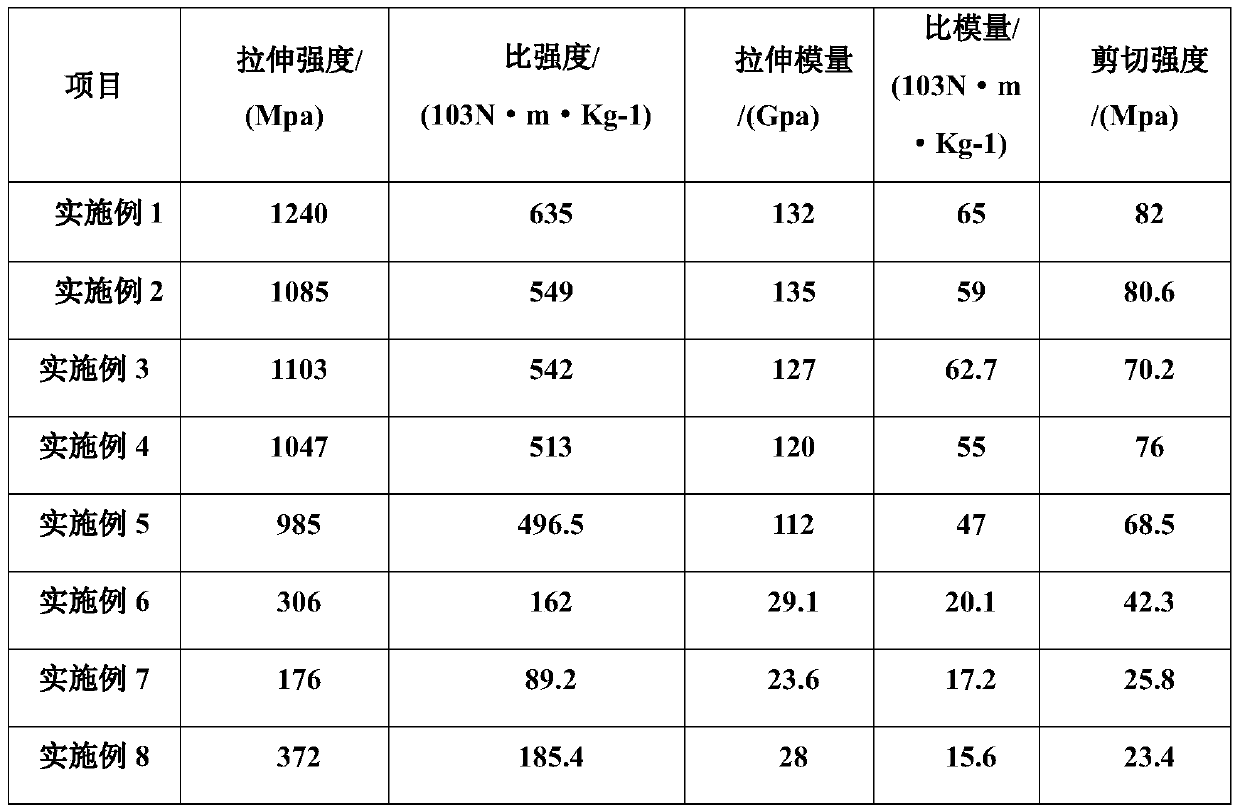

Embodiment 1

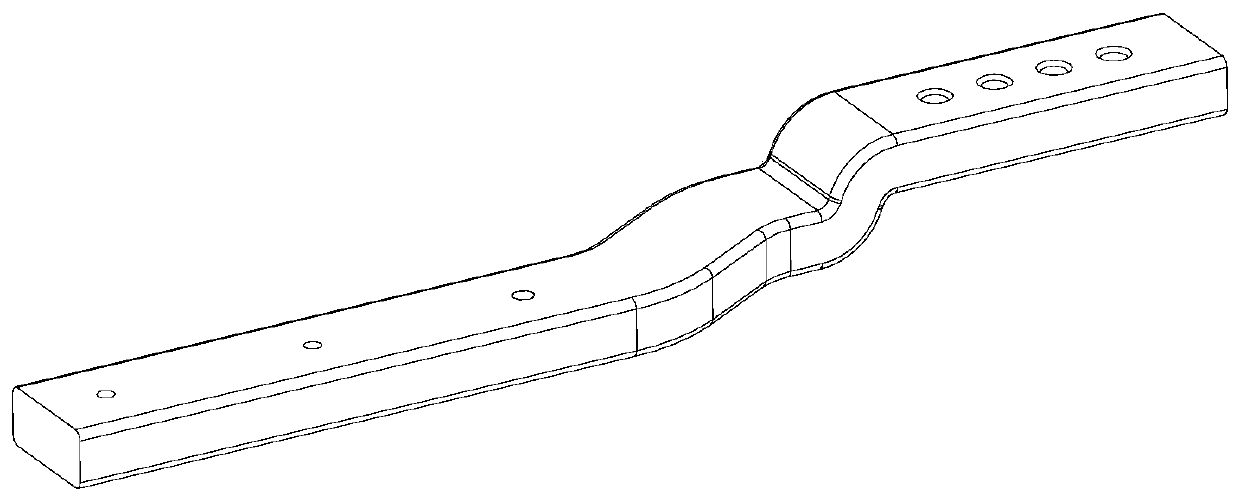

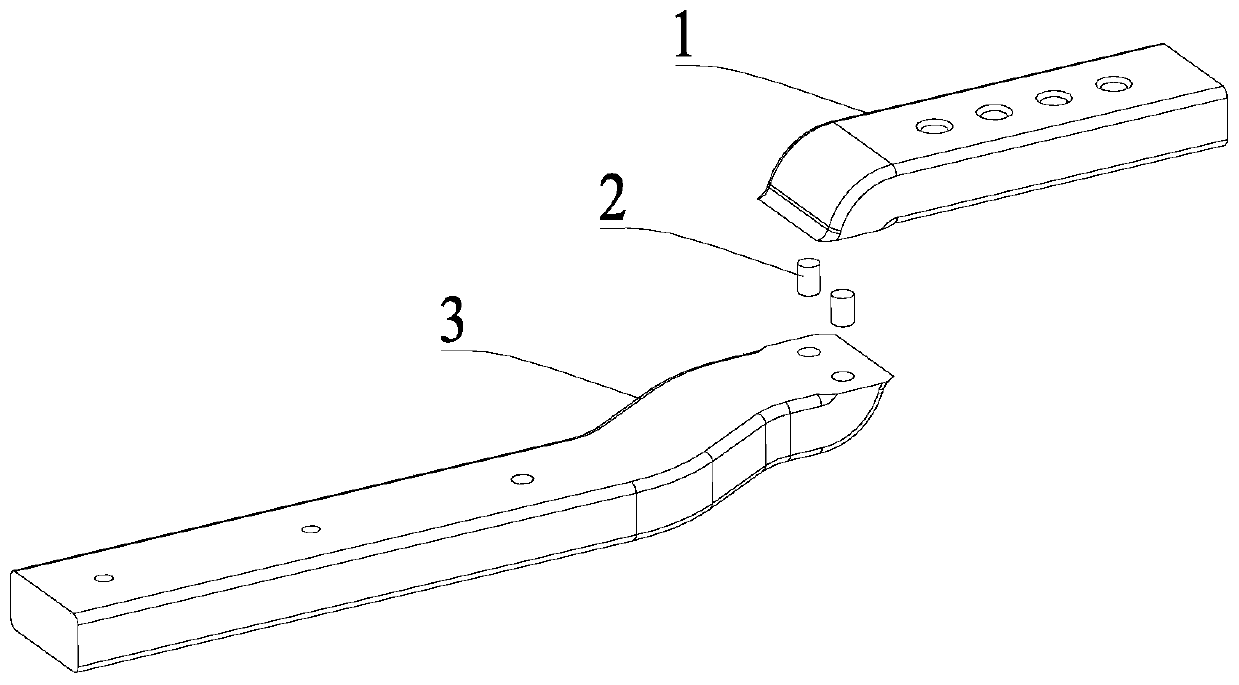

[0075] by figure 1 The carbon fiber prototype with the structure shown is taken as an example, and its preparation method includes:

[0076] Step 1. Preparation of carbon fiber blocks:

[0077] (1) According to the design requirements of the mechanical structure, 10 carbon fiber prepregs of the same specification are cut and laid layer by layer, and then the 10 layers of carbon fiber prepregs that have been laid layer by layer are placed on the cold press machine Pressurized to 90kgf / cm 2 Treat under pressure for 10 minutes to obtain a preformed body; repeat this step 10 times to obtain 10 preformed bodies.

[0078](2) Lay the above 10 pieces of preformed bodies one by one from bottom to top, and then place the 10 pieces of preformed bodies on the pallet of the hot press and pressurize at room temperature to 50kgf / cm2 for pre-pressurization. Treat for 10 minutes, so that the preforms are fully pressed and compacted; then the hot press is heated at a rate of 2°C / min to 75°C,...

Embodiment 2

[0090] by figure 1 The carbon fiber prototype with the structure shown is taken as an example, and its preparation method includes:

[0091] Step 1. Preparation of carbon fiber blocks:

[0092] (1) According to the design requirements of the mechanical structure, 10 carbon fiber prepregs of the same specification are cut and laid layer by layer, and then the 10 layers of carbon fiber prepregs that have been laid layer by layer are placed on the cold press machine Pressurized to 100kgf / cm 2 Treat under pressure for 8 minutes to obtain a preformed body; repeat this step 10 times to obtain 10 preformed bodies.

[0093] (2) Lay the above 10 pieces of preformed bodies one by one from bottom to top, and then place the 10 pieces of preformed bodies on the pallet of the hot press and pressurize at room temperature to 80kgf / cm2. Treat for 8 minutes to fully press and tighten the preforms; then raise the temperature of the hot press at a rate of 4°C / min to 80°C and press the 10 prefo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com