A kind of single-phase multiferroic ceramics with non-stoichiometric ratio of Olivieris structure and preparation method thereof

A non-stoichiometric, multiferroic ceramic technology, applied in the preparation of test samples, etc., can solve the problems of resistance and ferroelectric performance damage, material leakage, low resistivity, etc., achieve material resistance improvement and speed up production cycle , The effect of leakage current reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

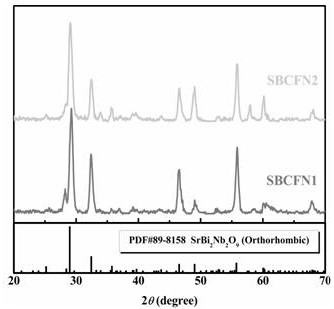

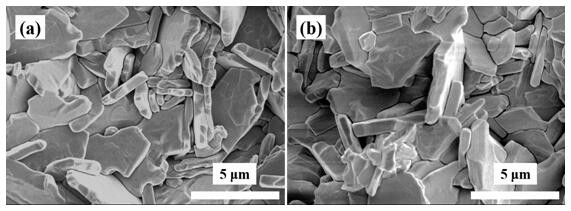

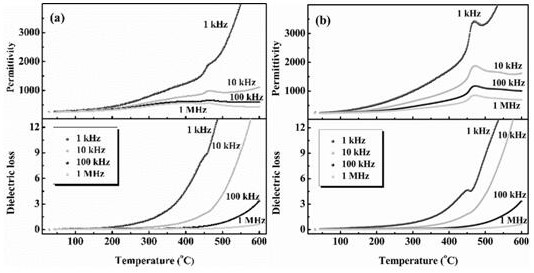

[0031] A Single-Phase SrBi with Nonstoichiometric Olivieris Structure 2 Nb 1.8 (Fe 0.1 Co 0.1 ) x O 9 The preparation method of multiferroic ceramics, wherein x represents the mole percentage, and x=1, and the specific steps include:

[0032] 1) According to the chemical formula SrBi 2 Nb 1.8 Fe 0.1 Co 0.1 O 9 Analytically pure SrCO 3 , Bi 2 O 3 , Nb 2 O 5 , Co 2 O 3 , and Fe 2 O 3 After preparation, it is uniformly mixed by ball milling, then dried, sieved, and then pre-fired at 800°C for 4 hours to obtain massive solids;

[0033] 2) After pulverizing the massive solid, perform ball milling again, and sieve the product to obtain SrBi with uniform size 2 Nb 1.8 Fe 0.1 Co 0.1 O 9 powder;

[0034] 3) SrBi will be obtained 2 Nb 1.8 Fe 0.1 Co 0.1 O 9 The powder is poured into the mold to be pressed and formed, and the formed blank is demolded to obtain a well-shaped blank;

[0035] 4) SrBi will be obtained 2 Nb 1.8 Fe 0.1 Co 0.1 O 9 The powder is...

Embodiment 2

[0043] A Single-Phase SrBi with Nonstoichiometric Olivieris Structure 2 Nb 1.8 (Fe 0.1 Co 0.1 ) x O 9 The preparation method of multiferroic ceramics, wherein x represents the mole percentage, and x=5 / 3, and the specific steps include:

[0044] 1) According to the chemical formula SrBi 2 Nb 1.8 (Fe 0.1 Co 0.1 ) 5 / 3 O 9 Analytically pure SrCO 3 , Bi 2 O 3 , Nb 2 O 5 , Co 2 O 3 , and Fe 2 O 3 After preparation, it is uniformly mixed by ball milling, then dried, sieved, and then pre-fired at 800°C for 4 hours to obtain massive solids;

[0045] 2) After pulverizing the massive solid, perform ball milling again, and sieve the product to obtain SrBi with uniform size 2 Nb 1.8 (Fe 0.1 Co 0.1 ) 5 / 3 O 9 powder;

[0046] 3) SrBi will be obtained 2 Nb 1.8 (Fe 0.1 Co 0.1 ) 5 / 3 O 9 The powder is poured into the mold to be pressed and formed, and the formed blank is demolded to obtain a well-shaped blank;

[0047] 4) SrBi will be obtained 2 Nb 1.8 (Fe 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com