A kind of modified aluminum powder based on polydopamine interface regulation of nitramine explosive and preparation method

A nitramine explosive and interface control technology, applied in explosive processing equipment, explosives, offensive equipment, etc., can solve problems such as high viscosity, achieve the effect of increasing mass fraction, high density, and improving the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

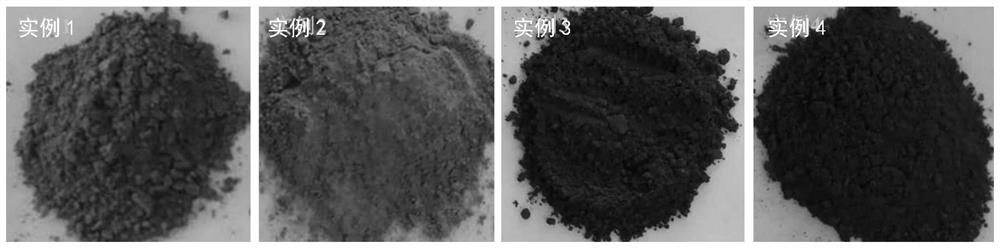

example 1

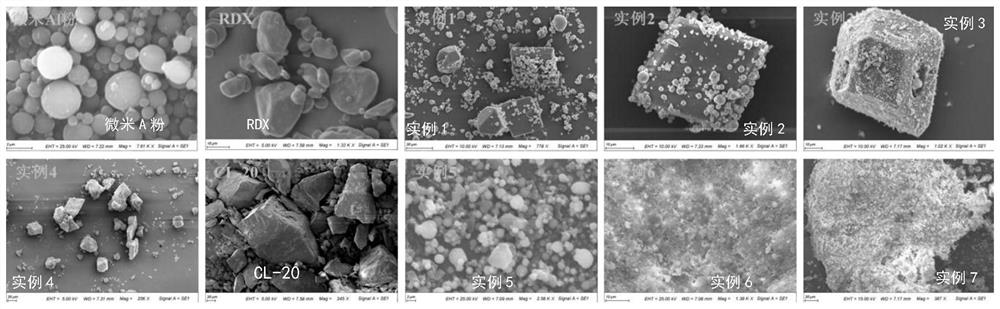

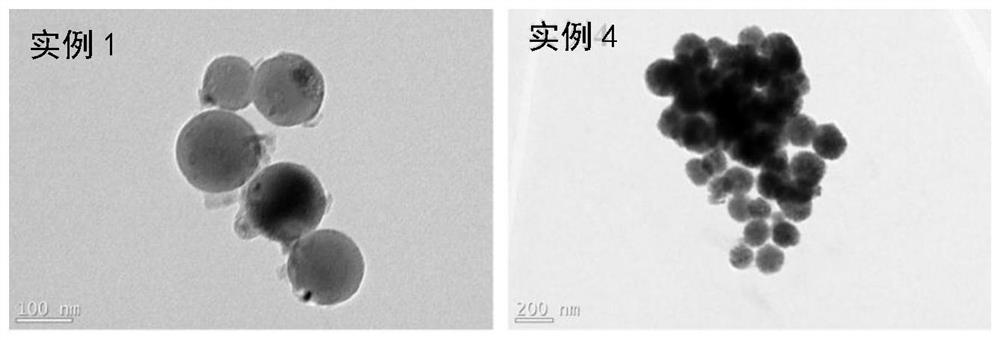

[0030] A method for preparing aluminum powder coated with nitroamine explosive based on polydopamine interface regulation, comprising the following process steps:

[0031] (1) Polydopamine coated on the surface of aluminum powder: Add 0.36g of dopamine and 0.2g of TRIS buffer solution (PH=8.5) into 200ml of distilled water, stir for 10min to partially polymerize the dopamine molecules, then add 3.6g of micron aluminum powder ( 1-2 μm) and stirred for 8 hours so that polydopamine grows in situ on the surface of the aluminum powder to form a polydopamine layer, and the solution is dried to obtain an aluminum powder whose surface is evenly coated with polydopamine.

[0032] (2) Mixing of aluminum powder and ammonium nitrate explosive: Weigh 0.4g of RDX and 0.4g of micron aluminum powder (particle size 1-2μm) coated with polydopamine on the surface, add to 10ml of dimethyl The sulfoxide solution was stirred with a magnetic stirrer at 70°C for 30 minutes until the ammonium nitrate ...

example 2

[0042] A method for preparing aluminum powder coated with nitroamine explosive based on polydopamine interface regulation, comprising the following process steps:

[0043] (1) Polydopamine coated on the surface of aluminum powder: same as Example 1.

[0044] (2) Mixing of aluminum powder and ammonium nitrate explosive: Weigh 0.6g of RDX and 0.3g of micron aluminum powder (particle size 1-2μm) coated with polydopamine on the surface, add to 12ml of dimethyl The sulfoxide solution was stirred with a magnetic stirrer at 70°C for 30 minutes until the ammonium nitrate was completely dissolved, and then ultrasonicated for 20 minutes with an ultrasonic cleaner.

[0045] (3) Precipitation of composite energetic crystals: Slowly and uniformly drop 25 ml of distilled water into the above solution to precipitate crystals.

[0046] (4) Collection of the product: the product was washed with distilled water, filtered, dried and collected in an oven, and the yield was calculated to be 90.0%...

example 3

[0053] A method for preparing aluminum powder coated with nitroamine explosive based on polydopamine interface regulation, comprising the following process steps:

[0054] (1) Polydopamine coated on the surface of aluminum powder: Same as Example 1, replace the micron aluminum powder with nano aluminum powder (average particle diameter 70nm) of the same quality.

[0055] (2) Mixing of aluminum powder and ammonium nitrate explosive: Weigh 0.4g of RDX and 0.4g of nano-aluminum powder (average particle size 70nm) coated with polydopamine on the surface, add to 10ml of dimethyl sulfoxide The solution was stirred with a magnetic stirrer at a temperature of 70°C for 30 minutes until the ammonium nitrate was completely dissolved, and then ultrasonicated for 20 minutes with an ultrasonic cleaner.

[0056] (3) Precipitation of composite energetic crystals: Slowly and uniformly drop 20 ml of distilled water into the above solution to precipitate crystals.

[0057] (4) Collection of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com