Heterojunction nano-material electrocatalyst, and applications thereof in CO2 reduction

A technology of electrocatalysts and nanomaterials, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of low directional conversion rate and generally poor activity of reduced electrocatalysts, and achieve easy operation, good economic and environmental benefits, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

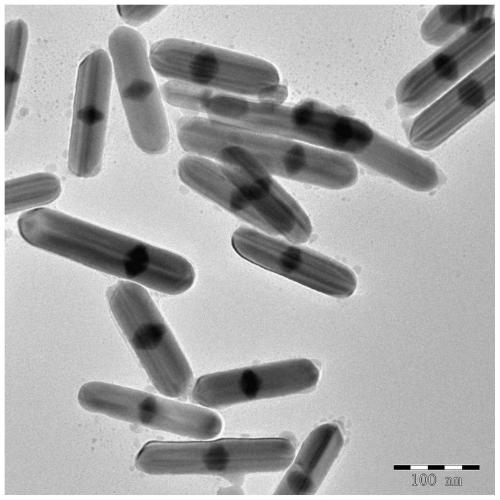

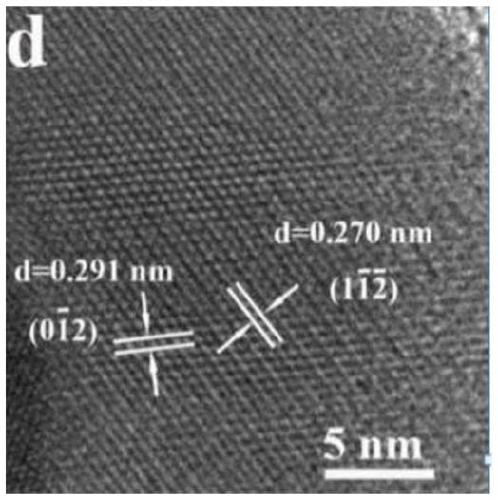

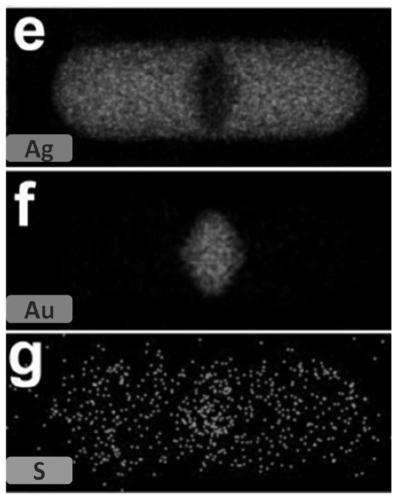

[0035] Embodiment 1 prepares Au-Ag / Ag 2 S heterojunction nanocatalyst

[0036] (1) Add 90mg polyvinylpyrrolidone (K30), 620mg cetyltrimethylammonium chloride 450μL, chloroauric acid with a concentration of 48.56mM, 1000μL silver nitrate with a concentration of 102mM and 8.6mL of water, stirred for 4min to make it evenly mixed to obtain a mixed solution;

[0037] (2) The mixed solution obtained in step (1) is placed in the hydrothermal kettle, after the hydrothermal kettle and the lining are sealed, the gas is charged and the initial pressure is set to 0.8Mpa, and the reaction temperature of the hydrothermal kettle is controlled at 200℃, the hydrothermal reaction time is controlled at 20h, and Ag-Au-Ag heterojunction nanorods with good dispersion are obtained;

[0038] (3) Cool to room temperature after the reaction in step (2), take out the Ag-Au-Ag heterojunction nanorods, and disperse them in 6 mL of water after centrifuging and washing for 3 times to obtain the Ag-Au-Ag h...

Embodiment 2

[0040] Example 2 Au-Ag / Ag 2 S heterojunction nanoelectrocatalysis for CO 2 Restoration method

[0041] (1) in 0.5M KHCO 3 Continuously pass CO in the solution at a rate of 10-60mL / min 2 Gas, Au-Ag / Ag assembled on 1cm*1cm FTO conductive glass surface 2 The S heterojunction nanocatalyst is used as the working electrode, and the linear sweep voltammetry test is performed at a scan rate of 50mV / s in the range of -0.3V to -1.0V;

[0042] (2) Experiments show that Au-Ag / Ag 2 S has superior electrocatalytic CO 2 Reduction activity, the current density at -0.95V reaches -310mA / mg;

[0043] (3) The amounts of ethanol and methanol in the carbon-containing products collected after electrolysis with a voltage of -0.95V for 1 hour are 300 μmol / (h*mg) and 520 μmol / (h*mg), respectively, and the Faradaic efficiency of ethanol is about 70 %

Embodiment 3

[0044] Example 3 Au-Ag / Ag 2 S heterojunction nanoelectrocatalysis for CO 2 Restoration method

[0045] (1) in 0.5M NaHCO 3 Continuously pass CO in the solution at a rate of 10-60mL / min 2 Gas, Au-Ag / Ag assembled on 1cm*1cm FTO conductive glass surface 2 The S heterojunction nanocatalyst is used as the working electrode, and the linear sweep voltammetry test is performed at a scan rate of 50mV / s in the range of -0.3V to -1.0V;

[0046] (2) The amounts of ethanol and methanol in the carbon-containing products collected after electrolysis with a voltage of -0.75V for 1 hour are 180 μmol / (h*mg) and 670 μmol / (h*mg), respectively, and the Faradaic efficiency of ethanol is about 50 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com