Fabric printing and dyeing pretreatment refining agent and preparing method thereof

A refining agent and fabric technology, applied in the field of fabric dyeing and pre-processing refining agent and its preparation, can solve the problems of unenvironmental protection, heavy odor of amine compounds, etc., and achieve the effects of reducing COD, reducing use cost and shortening process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

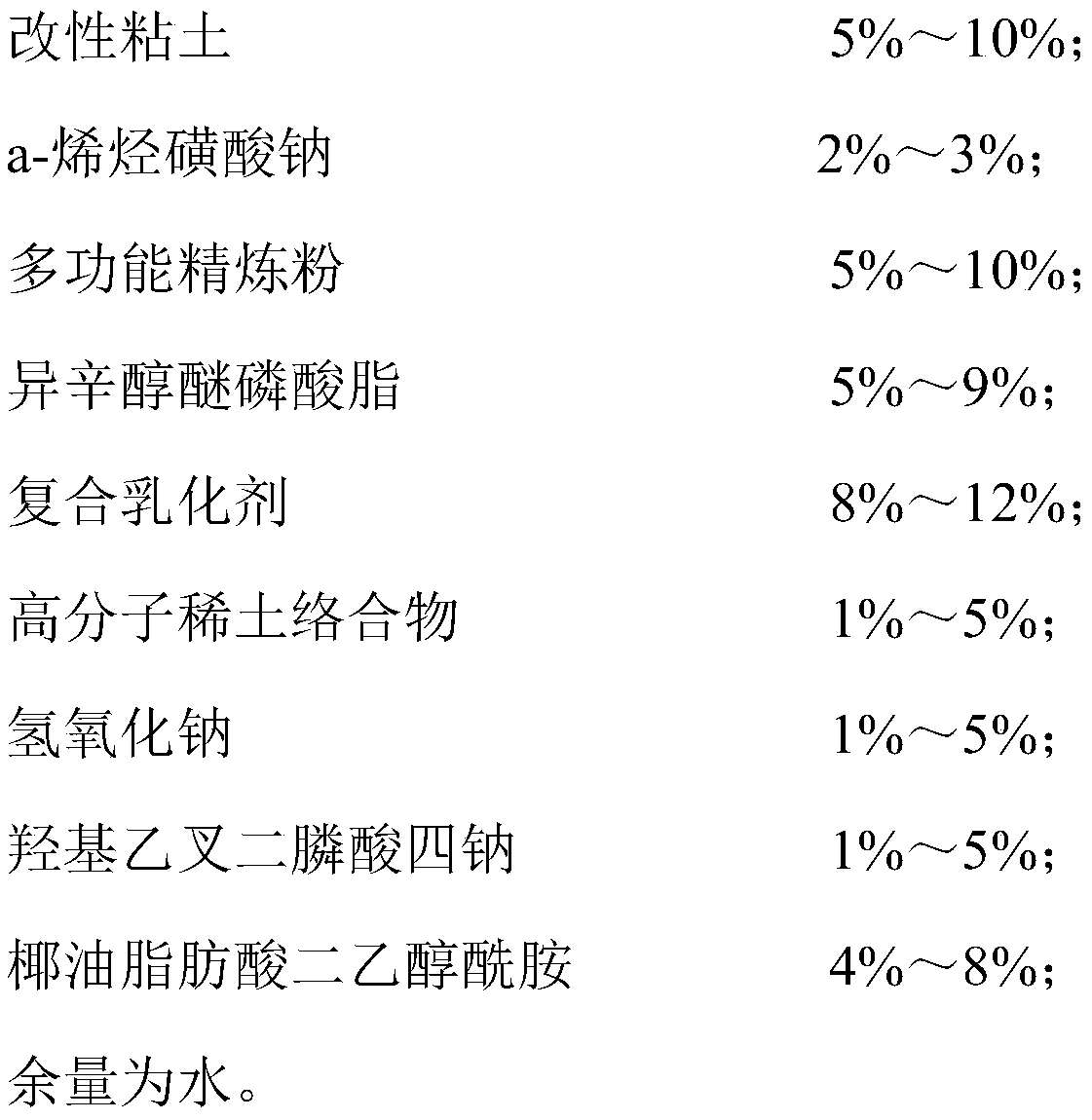

Method used

Image

Examples

Embodiment 1

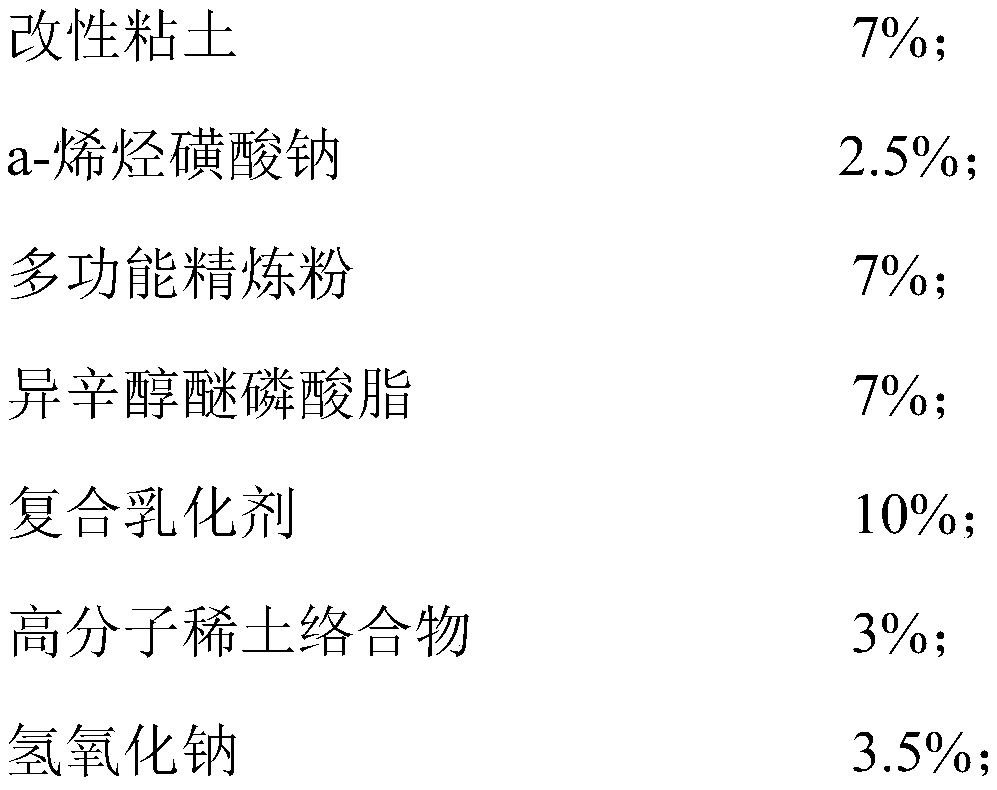

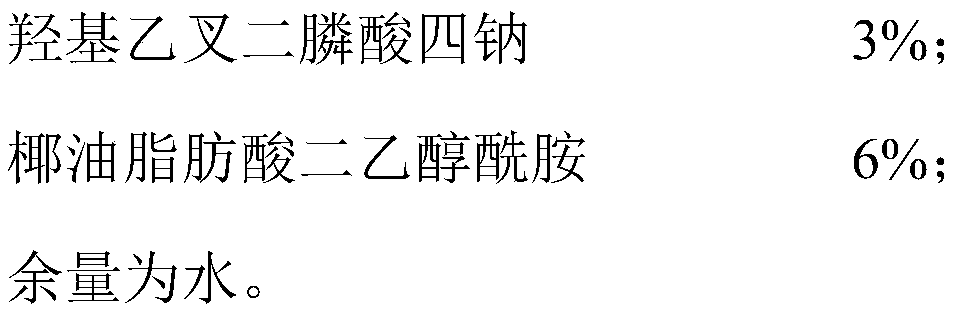

[0039] A kind of refining agent for pretreatment of fabric printing and dyeing provided in this embodiment comprises the following raw materials by weight percentage: 7% of modified clay, 2.5% of sodium α-olefin sulfonate, 7% of multifunctional refining powder, isooctyl ether Phosphate 7%, complex emulsifier 10%, polymer rare earth complex 3%, sodium hydroxide 3.5%, tetrasodium hydroxyethylidene diphosphonate 3%, coconut oil fatty acid diethanolamide 6%, the balance is water .

[0040] Its preparation method is as follows: the natural clay is modified by high-temperature roasting at 400°C, and deionized water, coconut oil fatty acid diethanolamine, compound emulsifier, and isooctyl ether phosphate are added to a reaction kettle equipped with a thermometer and a stirrer. , sodium hydroxide, and then stirred and heated to raise the temperature. When the temperature rose to 90°C, multifunctional refining powder, tetrasodium hydroxyethyl diphosphonate, and sodium a-olefin sulfonat...

Embodiment 2

[0042]A kind of refining agent for pretreatment of fabric printing and dyeing provided in this embodiment comprises the following raw materials by weight percentage: modified clay 5%, sodium α-olefin sulfonate 2%, multifunctional refining powder 10%, isooctyl ether Phosphate ester 6%, composite emulsifier 8%, polymer rare earth complex 5%, sodium hydroxide 1%, tetrasodium hydroxyethylidene diphosphonate 5%, coconut oil fatty acid diethanolamide 5%, the balance is water .

[0043] The preparation method is as follows: modify the natural clay by roasting at a high temperature of 350°C, add deionized water, coconut oil fatty acid diethanolamine, compound emulsifier, and isooctyl ether phosphate to a reaction kettle equipped with a thermometer and a stirrer. , sodium hydroxide, and then stirred and heated to raise the temperature. When the temperature rose to 100°C, multifunctional refining powder, tetrasodium hydroxyethyl diphosphonate, and sodium a-olefin sulfonate were added, a...

Embodiment 3

[0045] A kind of refining agent for pretreatment of fabric printing and dyeing provided in this embodiment comprises the following raw materials by weight percentage: 10% of modified clay, 3% of sodium α-olefin sulfonate, 7% of multifunctional refining powder, isooctyl ether 7% phosphate ester, 8% composite emulsifier, 2% polymer rare earth complex, 5% sodium hydroxide, 2% tetrasodium hydroxyethylidene diphosphonate, 7% coconut oil fatty acid diethanolamide, and the balance is water .

[0046] The preparation method is as follows: modify the natural clay by roasting at a high temperature of 450°C, add deionized water, coconut oil fatty acid diethanolamine, compound emulsifier, and isooctyl ether phosphate to a reaction kettle equipped with a thermometer and a stirrer. , sodium hydroxide, and then stirred and heated to raise the temperature. When the temperature rose to 85°C, multifunctional refining powder, tetrasodium hydroxyethyl diphosphonate, and sodium a-olefin sulfonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com