Binary-particle retention-assisting drainability-assisting system for nano-cellulose and application method

A nano-cellulose and microparticle retention technology, which is applied in the direction of adding retention aids, can solve the problems of inability to effectively improve the water filtration performance of nano-cellulose, long dehydration time, and poor production efficiency, and achieve outstanding industrial application effects. , improve product quality and output, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 1 part of nanocellulose, 999 parts of deionized water, 0.0001 part of polyvinylpyrrolidone with a molecular weight of 100,000, stir for 1 min at a stirring speed of 1000 r / min, and add 0.002 parts of hectorite nanoparticles with a particle size of 200 nm. For hydrogel, stir for 1 min at a stirring speed of 1500 r / min, pour it into a G2 filter with a microporous membrane (pore diameter 0.65 μm), turn on vacuum filtration, and prepare a quantitative volume of about 30 g / m 2 The nanocellulose film, and then peel off the paper, using a hot press at 100 o After drying at C for 10 min, a transparent film of nanocellulose was obtained, the morphology of which was as follows figure 1 , figure 2 shown. After measurement, the water filtration time is 102 minutes, the retention rate is 82%, the light transmittance is 84%, and the haze is 73%.

Embodiment 2

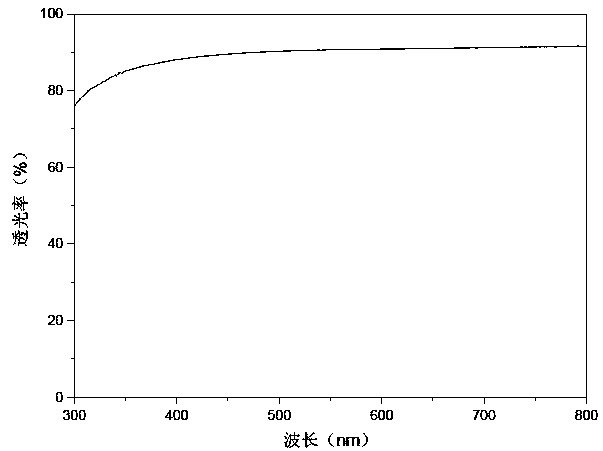

[0032] Take 1 part of nanocellulose, 999 parts of deionized water, and 0.001 part of polyvinylpyrrolidone with a molecular weight of 1.5 million, stir for 1 min at a stirring speed of 1000 r / min, and add 0.002 parts of hectorite nanoparticles with a particle size of 10 nm. For hydrogel, stir for 1 min at a stirring speed of 1500 r / min, pour it into a G2 filter with a microporous membrane (pore diameter 0.65 μm), turn on vacuum filtration, and prepare a quantitative volume of about 30 g / m 2 The nanocellulose film, and then peel off the paper, using a hot press at 100 o C dried for 10min to obtain a nanocellulose transparent film with a morphology as figure 1 , figure 2 shown. After measurement, the water filtration time is 79 minutes, the retention rate is 94%, and the light transmittance is 89% (such as image 3 shown), the haze is 69%.

Embodiment 3

[0034] Take 1 part of nanocellulose, 999 parts of deionized water, and 0.003 parts of polyvinylpyrrolidone with a molecular weight of 216,000, stir for 1 min at a stirring speed of 1000 r / min, and add 0.002 parts of hectorite nanoparticles with a particle size of 20 nm. For hydrogel, stir for 1 min at a stirring speed of 1500 r / min, pour it into a G2 filter with a microporous membrane (pore diameter 0.65 μm), turn on vacuum filtration, and prepare a quantitative volume of about 30 g / m 2 The nanocellulose film, and then peel off the paper, using a hot press at 100 o After drying at C for 10 min, a transparent film of nanocellulose was obtained, the morphology of which was as follows figure 1 , figure 2 shown. After measurement, the water filtration time is 55 minutes, the retention rate is 95%, and the light transmittance is 91% (such as image 3 shown), the haze is 66%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com