Turbocharger-equipped engine and method for operaing turbocharger-equipped engine

A turbocharger and engine technology, applied in machine/engine, combustion engine, engine control and other directions, can solve problems such as reduced efficiency, and achieve the effect of improving efficiency and improving engine output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

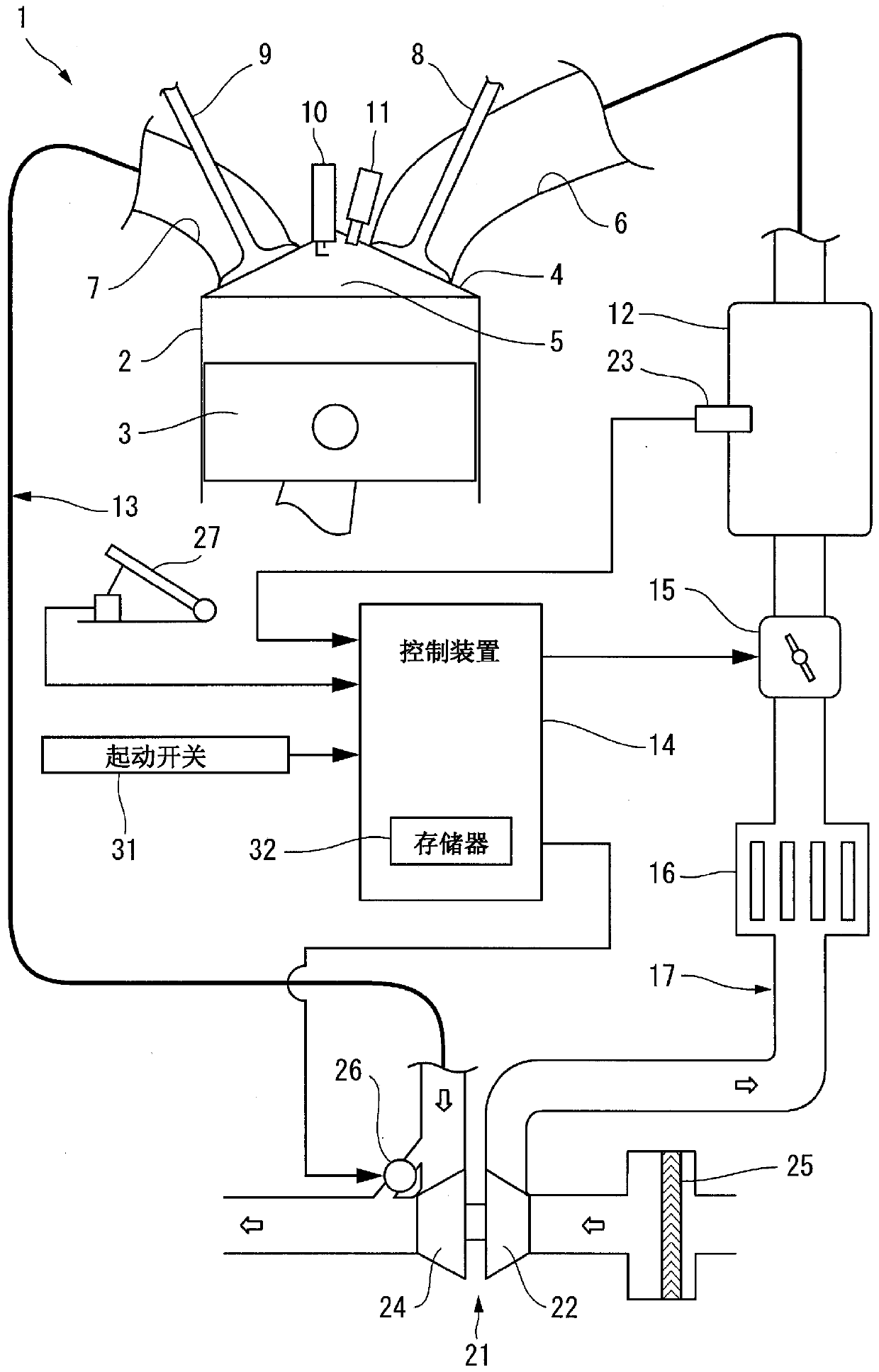

[0017] Below, use Figure 1 ~ Figure 3 One embodiment of an engine with a turbocharger and a method of operating the engine with a turbocharger according to the present invention will be described in detail.

[0018] figure 1 The shown engine 1 is a 4-stroke single-cylinder engine or a 4-stroke multi-cylinder engine, comprising cylinders 2 , pistons 3 and cylinder heads 4 .

[0019] The cylinder head 4 forms a combustion chamber 5 together with the above-mentioned cylinder 2 and piston 3 . Combustion chamber 5 is surrounded by cylinder 2 , piston 3 and cylinder head 4 .

[0020] The cylinder head 4 is formed with an intake port 6 and an exhaust port 7, and is provided with an intake valve 8, an exhaust valve 9, a spark plug 10, a fuel injector 11, and the like. The downstream end of the suction port 6 communicates with the combustion chamber 5 , and the upstream end communicates with the buffer tank 12 . The upstream end of the exhaust port 7 communicates with the combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com