Preparation method of water-based fireproof coating used for indoor walls

A fire-resistant coating, water-based technology, applied in the direction of fire-resistant coatings, conductive coatings, rosin coatings, etc., can solve the problems of increasing the cost of coating storage and transportation, affecting the use and storage and transportation of coatings, reducing the practicability of coatings, etc., to achieve enhanced long-term The ability to preserve time, prevent coating bubbles, and improve storage power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

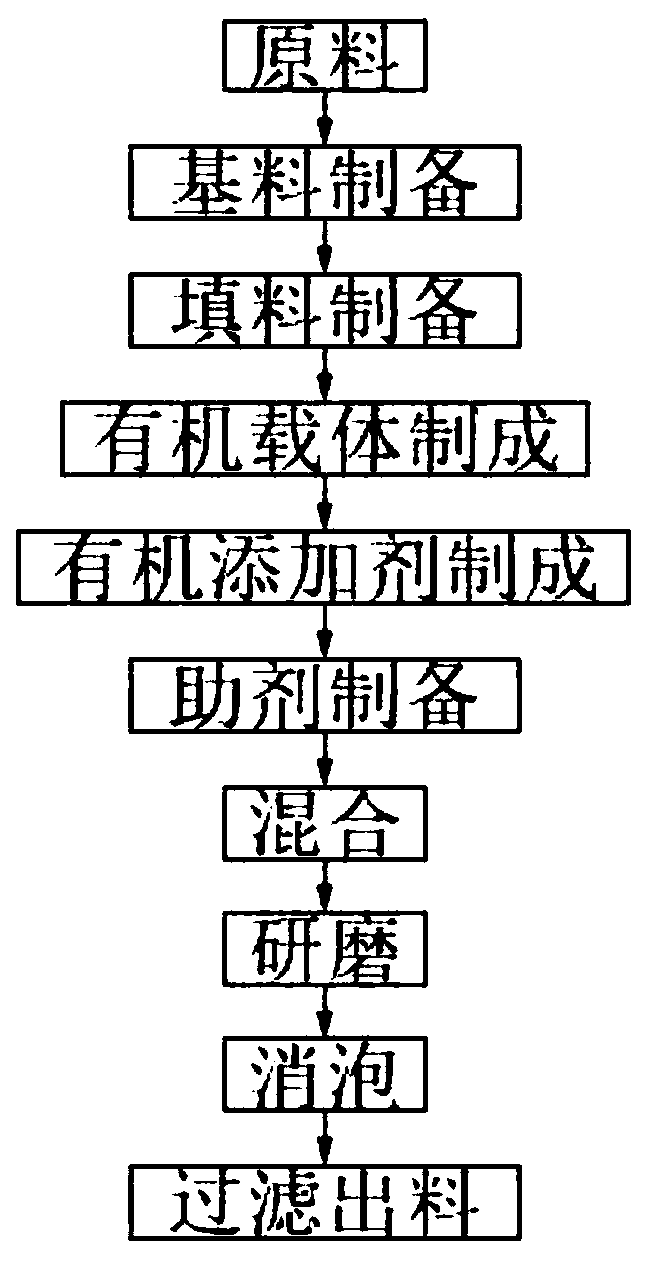

Image

Examples

Embodiment 1

[0027] The preparation method of the indoor wall water-based fireproof coating comprises the following steps:

[0028] S1: Raw materials: red phosphorus: 10 parts, aluminum hydroxide: 3 parts, solvent: 7 parts, adhesive: 12 parts, thixotropic agent: 7 parts, coupling agent: 4 parts, dispersant: 4 parts, fluid Leveling agent: 5 parts, defoamer: 2 parts, titanium dioxide: 9 parts, melamine: 6 parts, thickener: 1 part, film-forming aid: 3 parts, hydroxyethyl cellulose: 1 part, silica fume Stone powder: 2 parts, silicate: 1 part, ammonia water: 3 parts, vinegar-acrylic emulsion: 1 part, polyol: 17 parts, dibasic acid: 20 parts, fatty acid: 19 parts, distilled water: 50 parts.

[0029] S2: Base material preparation: put distilled water, polyol, dibasic acid and fatty acid aluminum into a high-speed dispersion tank and mix to prepare the base material;

[0030] S3: filler preparation: put red phosphorus and aluminum hydroxide into a high-speed dispersion tank and mix to prepare fil...

Embodiment 2

[0040] The preparation method of the indoor wall water-based fireproof coating comprises the following steps:

[0041] S1: Raw materials: red phosphorus: 16 parts, aluminum hydroxide: 5 parts, solvent: 8 parts, adhesive: 14 parts, thixotropic agent: 8 parts, coupling agent: 6 parts, dispersant: 6 parts, fluid Leveling agent: 8 parts, defoamer: 5 parts, titanium dioxide: 11 parts, melamine: 8 parts, thickener: 3 parts, film-forming aid: 4 parts, hydroxyethyl cellulose: 3 parts, silica fume Stone powder: 3 parts, silicate: 2 parts, ammonia water: 5 parts, vinegar acrylic emulsion: 3 parts, polyol: 20 parts, dibasic acid: 23 parts, fatty acid: 20 parts, distilled water: 60 parts.

[0042] S2: Base material preparation: put distilled water, polyol, dibasic acid and fatty acid aluminum into a high-speed dispersion tank and mix to prepare the base material;

[0043] S3: filler preparation: put red phosphorus and aluminum hydroxide into a high-speed dispersion tank and mix to prepar...

Embodiment 3

[0053] The preparation method of the indoor wall water-based fireproof coating comprises the following steps:

[0054] S1: Raw materials: red phosphorus: 20 parts, aluminum hydroxide: 7 parts, solvent: 10 parts, binder: 16 parts, thixotropic agent: 9 parts, coupling agent: 8 parts, dispersant: 8 parts, fluid Leveling agent: 10 parts, defoamer: 6 parts, titanium dioxide: 13 parts, melamine: 9 parts, thickener: 4 parts, film-forming aid: 5 parts, hydroxyethyl cellulose: 4 parts, silica fume Stone powder: 4 parts, silicate: 3 parts, ammonia water: 7 parts, vinegar acrylic emulsion: 5 parts, polyol: 26 parts, dibasic acid: 25 parts, fatty acid: 22 parts, distilled water: 70 parts.

[0055] S2: Base material preparation: put distilled water, polyol, dibasic acid and fatty acid aluminum into a high-speed dispersion tank and mix to prepare the base material;

[0056] S3: filler preparation: put red phosphorus and aluminum hydroxide into a high-speed dispersion tank and mix to prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com