Process method and system for combining hydrogenation and catalytic cracking

A technology for catalytic cracking and catalytic cracking of gasoline, applied in the field of hydrocarbon oil processing, can solve problems such as excessive gasoline cracking, loss of gasoline yield, and excessive gasoline condensation and coking, and achieve the effects of high efficiency conversion and high light oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0054] Preferred embodiment 1: Combine all of the catalytically cracked heavy cycle oil from step (1) with all of the catalytically cracked light cycle oil from step (3) and all of the catalytically cracked heavy cycle oil from step (3) The cycle oil is introduced into the hydrogenation unit in step (2) for hydrogenation reaction.

specific Embodiment approach 2

[0055] Preferred embodiment 2: all the catalytic cracking heavy cycle oil from step (1), all the catalytic cracking light cycle oil from step (1), and all the catalytic cracking light cycle oil from step (3) The cycle oil and all the catalytically cracked heavy cycle oil from step (3) are introduced into the hydrogenation unit of step (2) for hydrogenation reaction.

[0056] In the aforementioned preferred embodiment 1, the catalytically cracked light cycle oil from step (1) and the low-olefin catalytically cracked gasoline from step (3) are taken out of the unit as diesel products and gasoline products, respectively.

[0057] Preferably, the present invention can also introduce all the catalytically cracked light cycle oil from step (1) into a hydrogenation unit for hydrogenation reaction, and use the low-olefin catalytically cracked gasoline from step (3) as gasoline The product comes out of the device.

[0058] Preferably, the catalytic cracking oil slurry obtained in step...

Embodiment 1

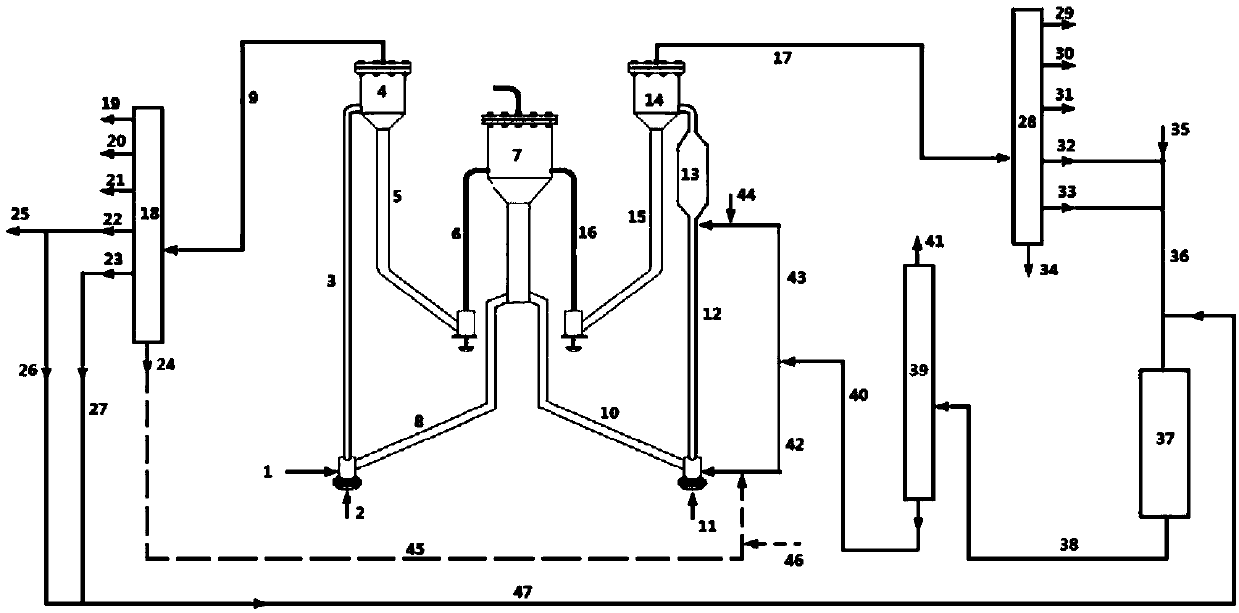

[0112] The residual hydrogenated tail oil A is used as the raw material, and its properties are shown in Table 1. use figure 1 The process flow shown is carried out.

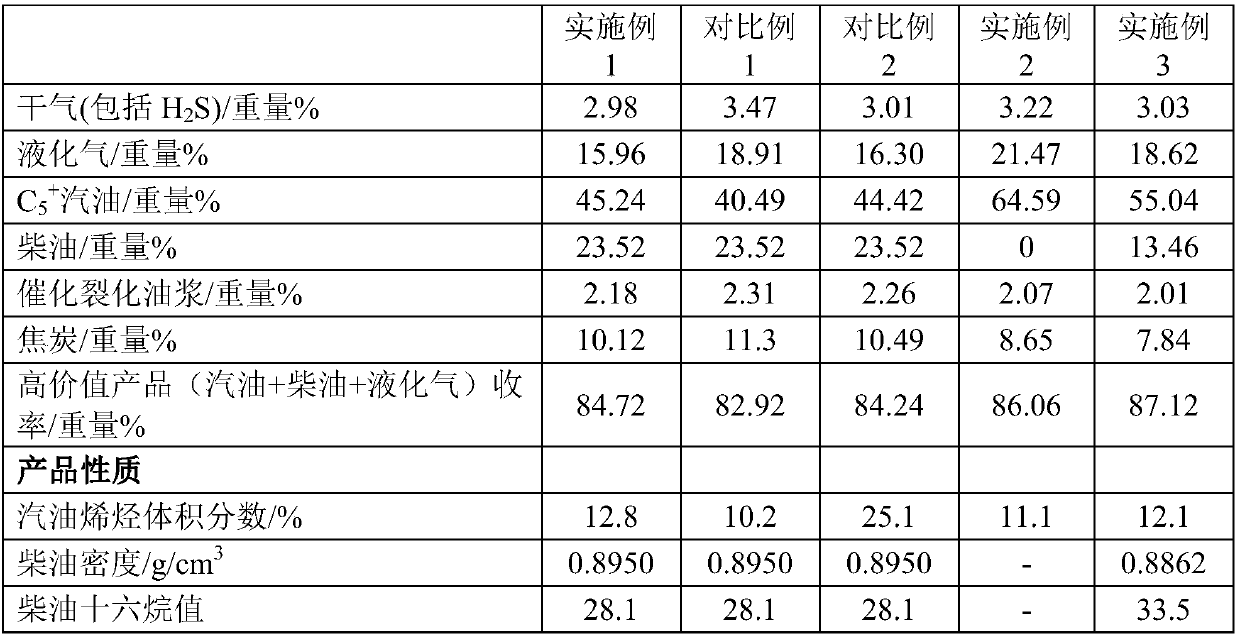

[0113] Residue hydrogenation tail oil A enters the first riser of the double riser medium-sized catalytic cracking test device, and contacts with water vapor and the catalyst from the regenerator to perform the first catalytic cracking reaction. The conditions of the first catalytic cracking reaction are: reaction temperature The temperature is 480°C, the agent-to-oil weight ratio is 6, and the residence time in the first riser is 1.5 seconds. After the reaction, oil and gas are separated to separate dry gas, liquefied gas, first riser catalytic cracking gasoline, first riser catalytic cracking light cycle oil, first riser catalytic cracking heavy cycle oil and first riser catalytic cracking oil pulp. The first riser catalytic cracking light cycle oil is all used as diesel products. All the first riser catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com