Detection system for spectral resolution of Rowland grating spectrometer

A technology of spectral resolution and Roland grating, applied in the field of detection system of spectral resolution of Roland grating spectrometer, can solve the problems of Roland grating curvature radius deviation, the actual spectral resolution cannot reach the design index, the slit width does not match the design value, etc. , to achieve the effect of good stability, low operating cost and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

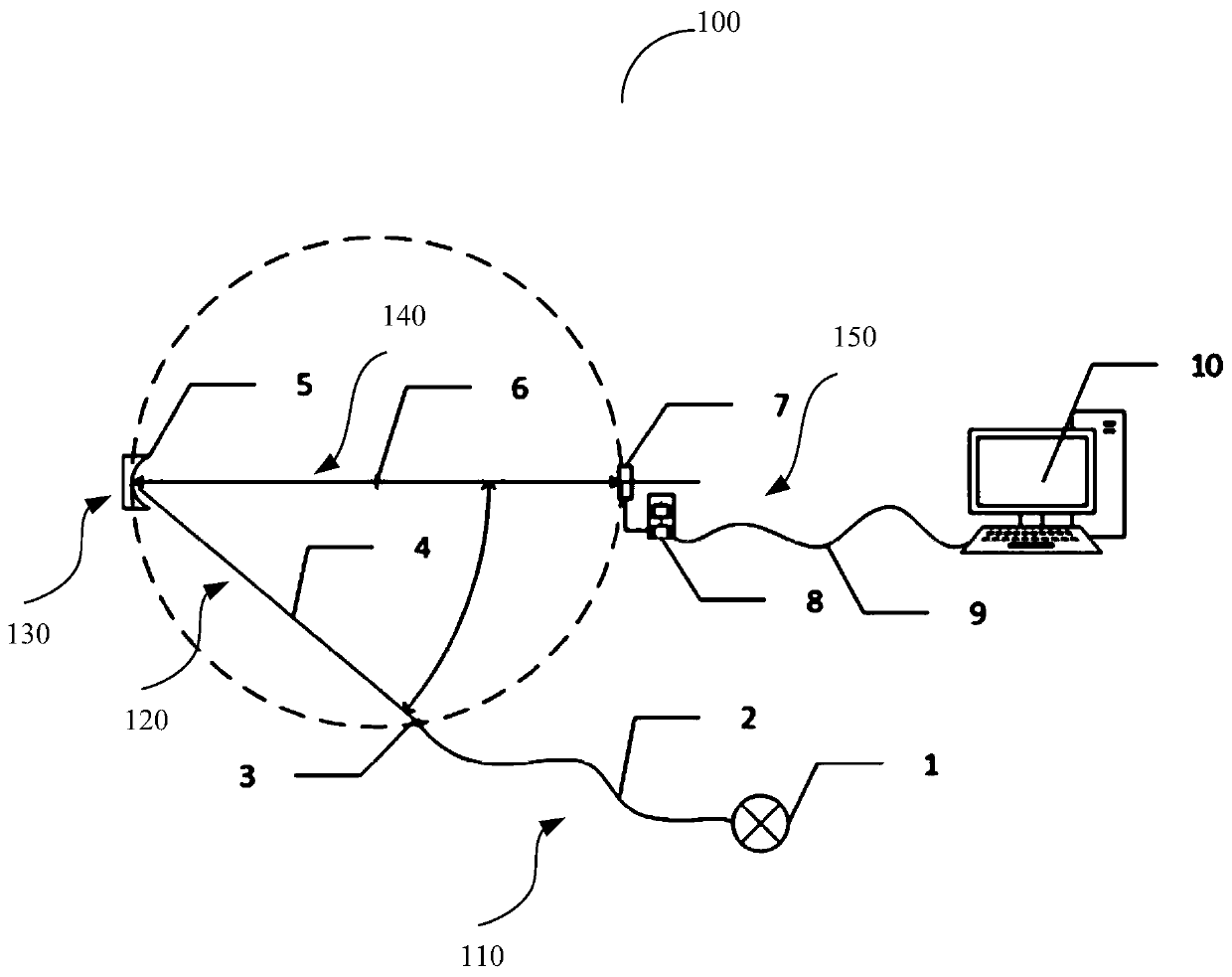

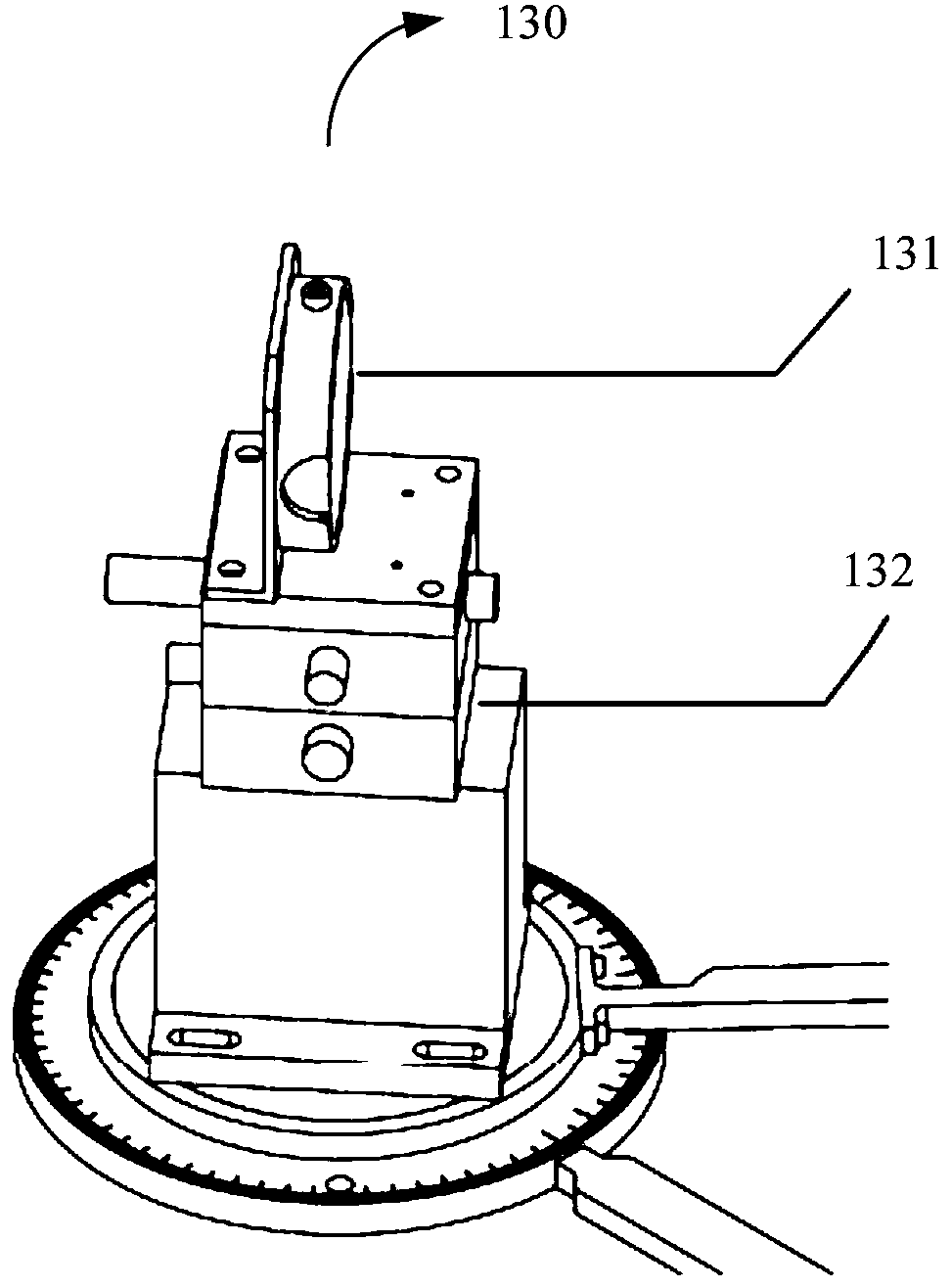

[0046] Taking the Roland grating spectrometer to be tested as an example with a radius of curvature R750mm; grating aperture Φ63.5mm; spectral order -1; groove density 2400g / mm; incident angle 40°; figure 1 This embodiment will be described.

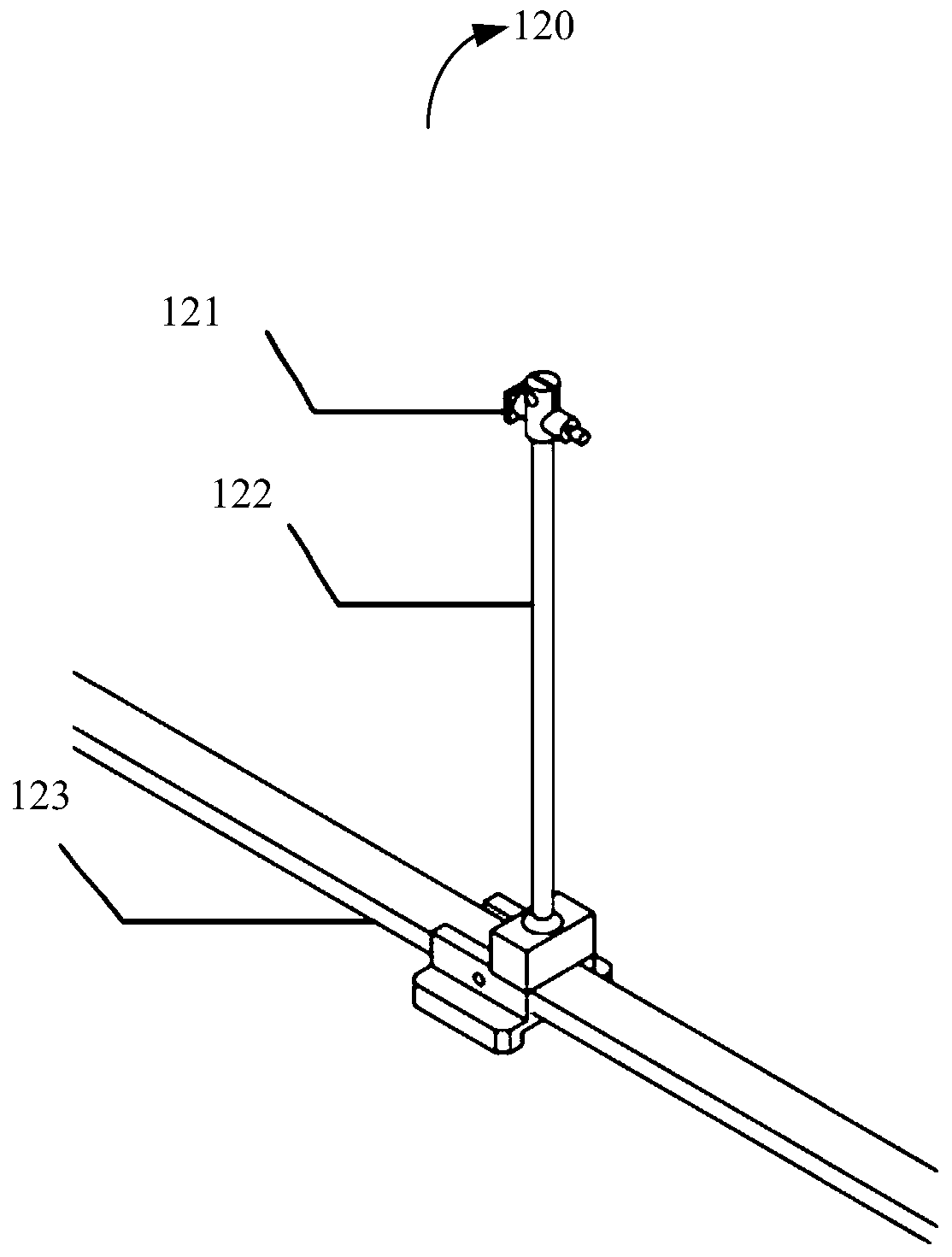

[0047] First use the laser to adjust the state of the grating to the test state, that is, the spectra of each order are on the same horizontal plane, and the image of the outgoing spectrum is parallel to the direction of the grating lines, and the Roland system to be tested is adjusted according to the design parameters by adjusting the incident cantilever. The front and rear positions and incident angles of the slits are connected to a line-spectrum light source such as a mercury lamp. According to the parameters such as the incident angle of the Roland grating, the length of the incident arm, the grating line, and the radius of curvature, the line-spectrum light source connected through the grating equation is relatively similar. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com