Chip glass packaging process

A technology of glass encapsulation and process, applied in the manufacture of encapsulation/shell resistors, resistor shells/packaging shells/potting, non-adjustable metal resistors, etc., can solve problems such as performance changes, changes, and chip defects, and achieve The effect of enhancing the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

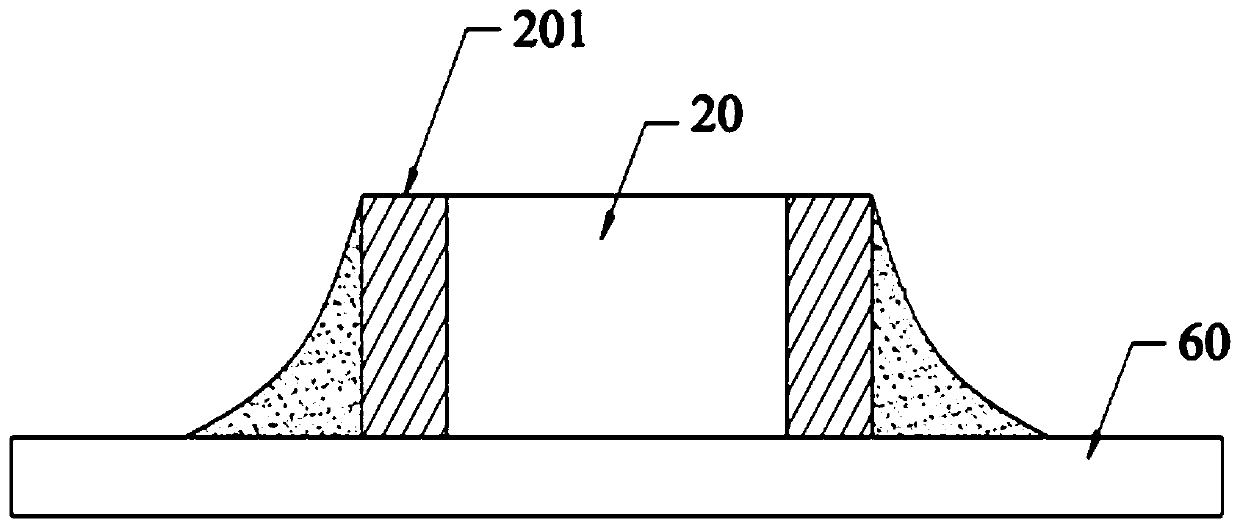

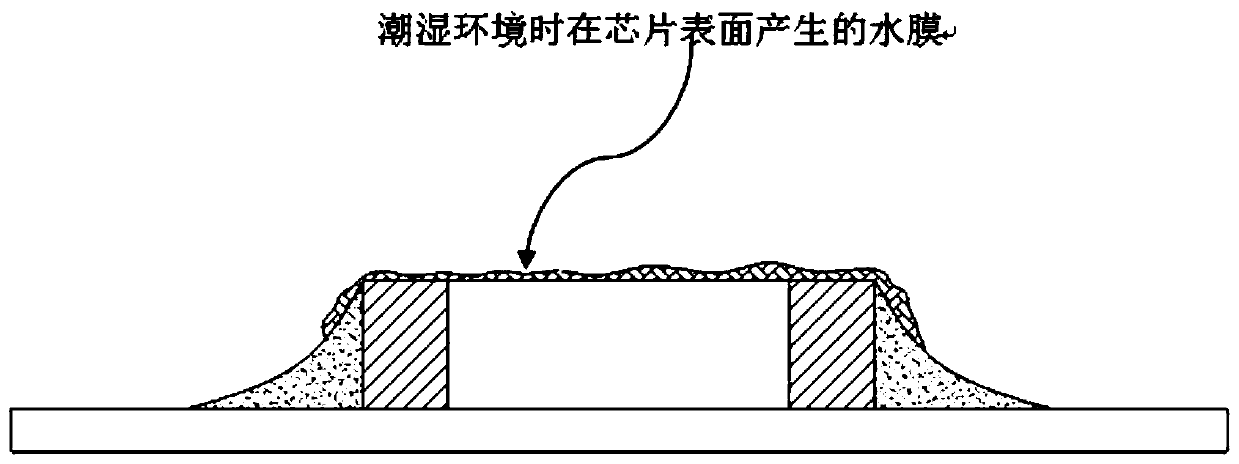

[0027] In the chip glass encapsulation process of the present invention, a layer of glass film is sputtered on the surface of the exposed part of the ceramic body in the thermistor chip to form the encapsulation.

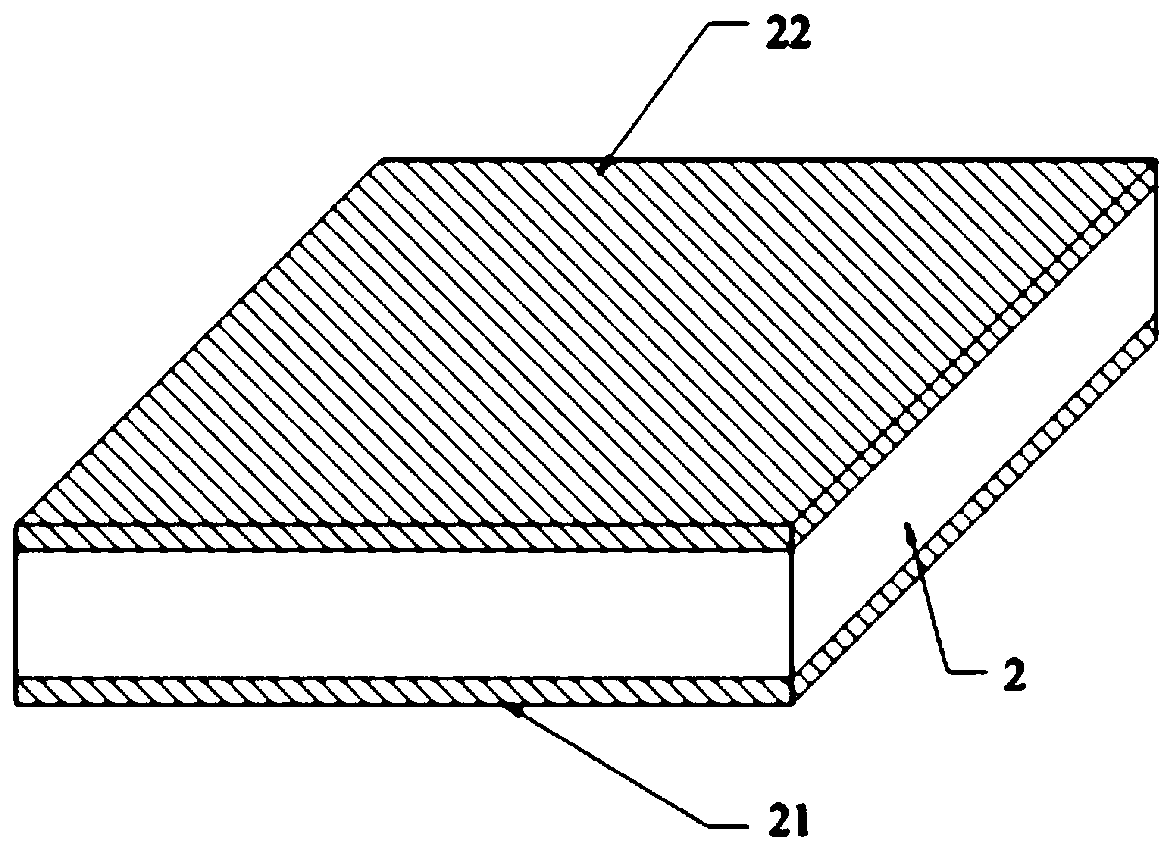

[0028] The ceramic body in the thermistor chip is a cube, and an electrode layer is respectively provided on the top surface and the bottom surface of the ceramic body.

[0029] The thermistor chip can be an existing thermistor chip with upper and lower electrode structures, or a thermistor chip with left and right electrode structures, specifically a chip chip with a model number of 0603, and the electrode layer is a silver layer.

[0030] The process specifically includes the following steps: cover the two electrode layers of the thermistor chip with a high temperature resistant film, then place the thermistor chip in the vacuum coating chamber of the vacuum sputtering coating equipment, and then apply the vacuum coating The chamber is evacuated to -90KPA, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com