Lithium ion battery, positive electrode sheet thereof and preparation method thereof

A lithium-ion battery and positive electrode technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as great processing safety, damage to electrolyte system, and impact on battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0155] The preparation process of the positive electrode sheet of the present embodiment is as follows:

[0156] 1) Preparation of lithium supplement material layer slurry: add lithium-containing compound, transition metal, conductive agent and PVDF into the ball mill tank according to the predetermined ratio above, add a certain volume of NMP solvent, and then use nitrogen or argon as an inert gas under the protection , or lower than -95Kp environment, perform high-speed ball milling, and separate the slurry after ball milling.

[0157] 2) Coating the slurry onto the current collector using a gravure roller, and drying to obtain a current collector coated with a lithium-replenishing material layer.

[0158] 3) Preparation of positive electrode sheet: add a certain amount of NMP solvent according to the mixture of positive electrode active material, conductive agent and binder in the predetermined ratio above, and disperse and stir evenly at high speed, and transfer or extrude...

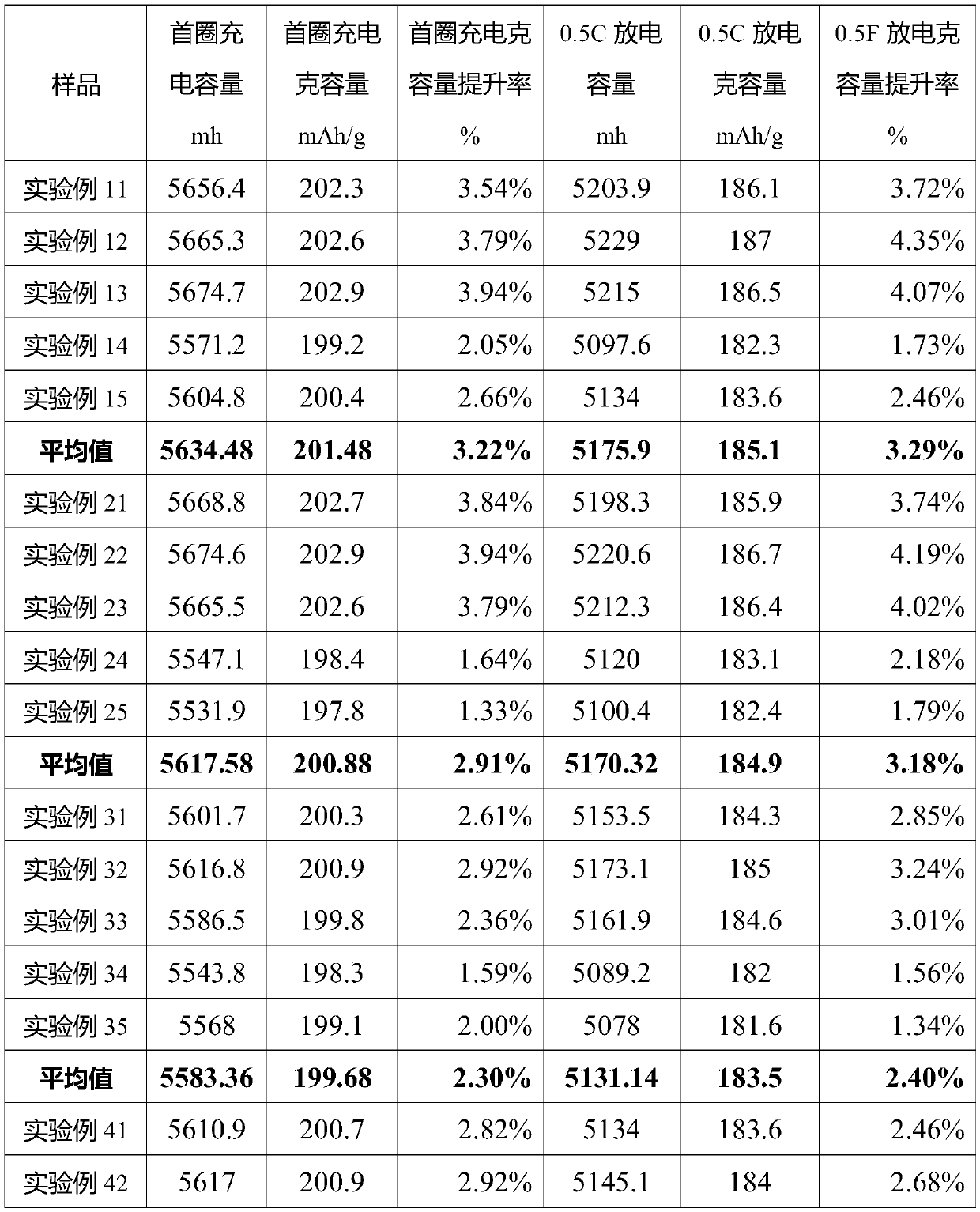

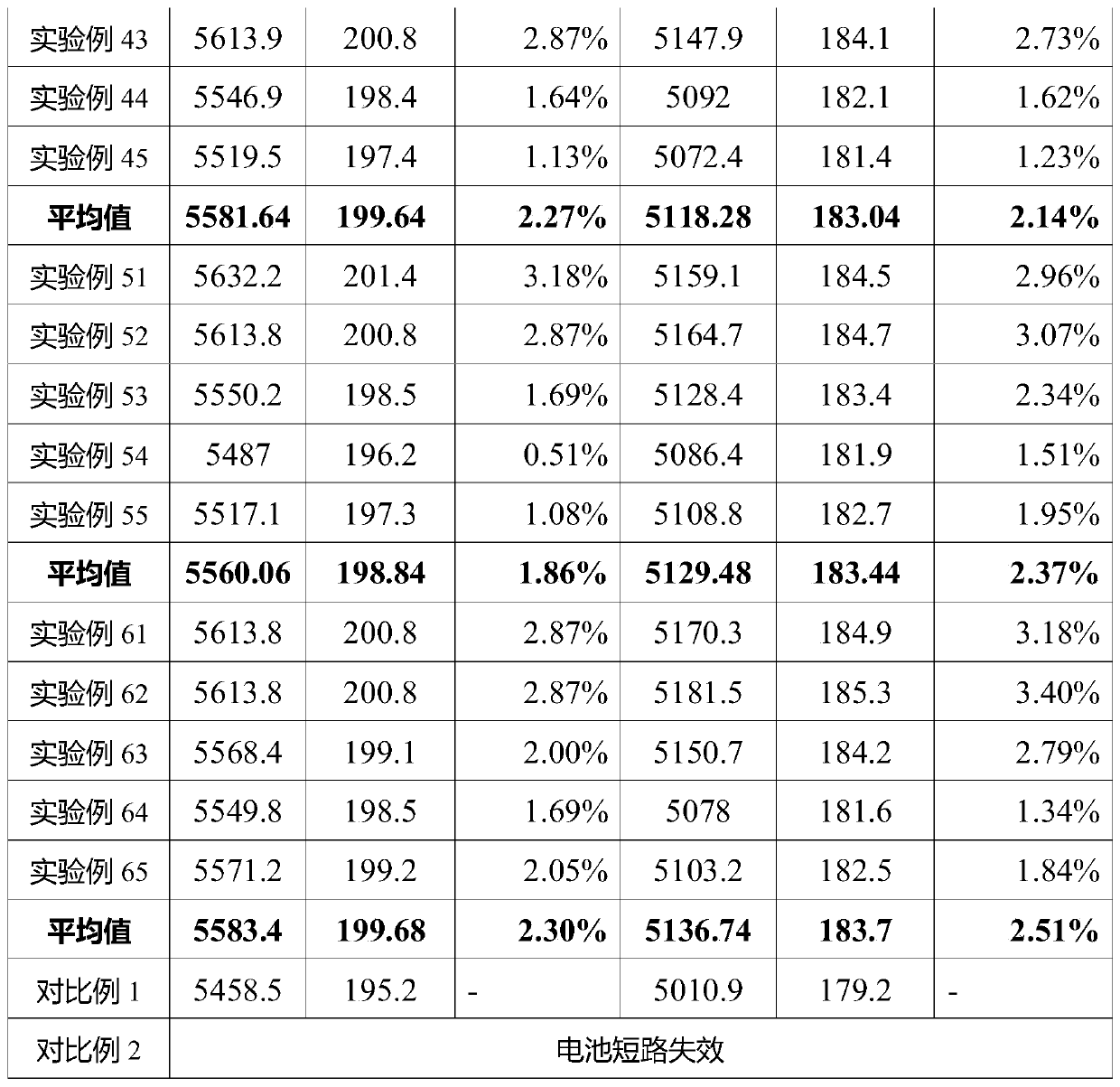

experiment example 11

[0170] 1. Preparation of positive electrode sheet

[0171] 1.1 Preparation of lithium-supplementing material layer

[0172] Will Li 2 S powder, Co powder, conductive carbon black (SP) and polyvinylidene fluoride (PVDF) were dispersed in N-methylpyrrolidone, and the slurry was formed by high-energy ball milling under nitrogen atmosphere for 12 h.

[0173] Among them, Li 2 The mass ratio of S:Co:SP:PVDF is: 58:37:2.5:2.5;

[0174] Coat the lithium-supplementing slurry on both sides of the aluminum foil (thickness 12 μm), and then dry at 90°C for 10 minutes to form a lithium-supplementing material layer on both sides of the aluminum foil. After drying, the coated surface density is 0.26 mg / cm2.

[0175] 1.2 Formation of positive electrode active material layer

[0176] Lithium cobaltate, conductive carbon black and polyvinylidene fluoride are dispersed in N-methylpyrrolidone to form positive electrode active material slurry. Wherein, the weight ratio of lithium cobaltate: co...

experiment example 12

[0182] Compared with Experimental Example 11, the only difference is that Li in this Experimental Example 12 2 The mass ratio of S: Co: SP: PVDF is: where, Li 2 The mass ratio of S:Co:SP:PVDF is: 59:38:1.5:1.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com