Wide-size-fraction flotation system and process

A flotation, wide-grain technology, applied in the wide-grain flotation system and process field, can solve the problems of complex wide-grain flotation process, environmental hazards, high energy consumption, etc. The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

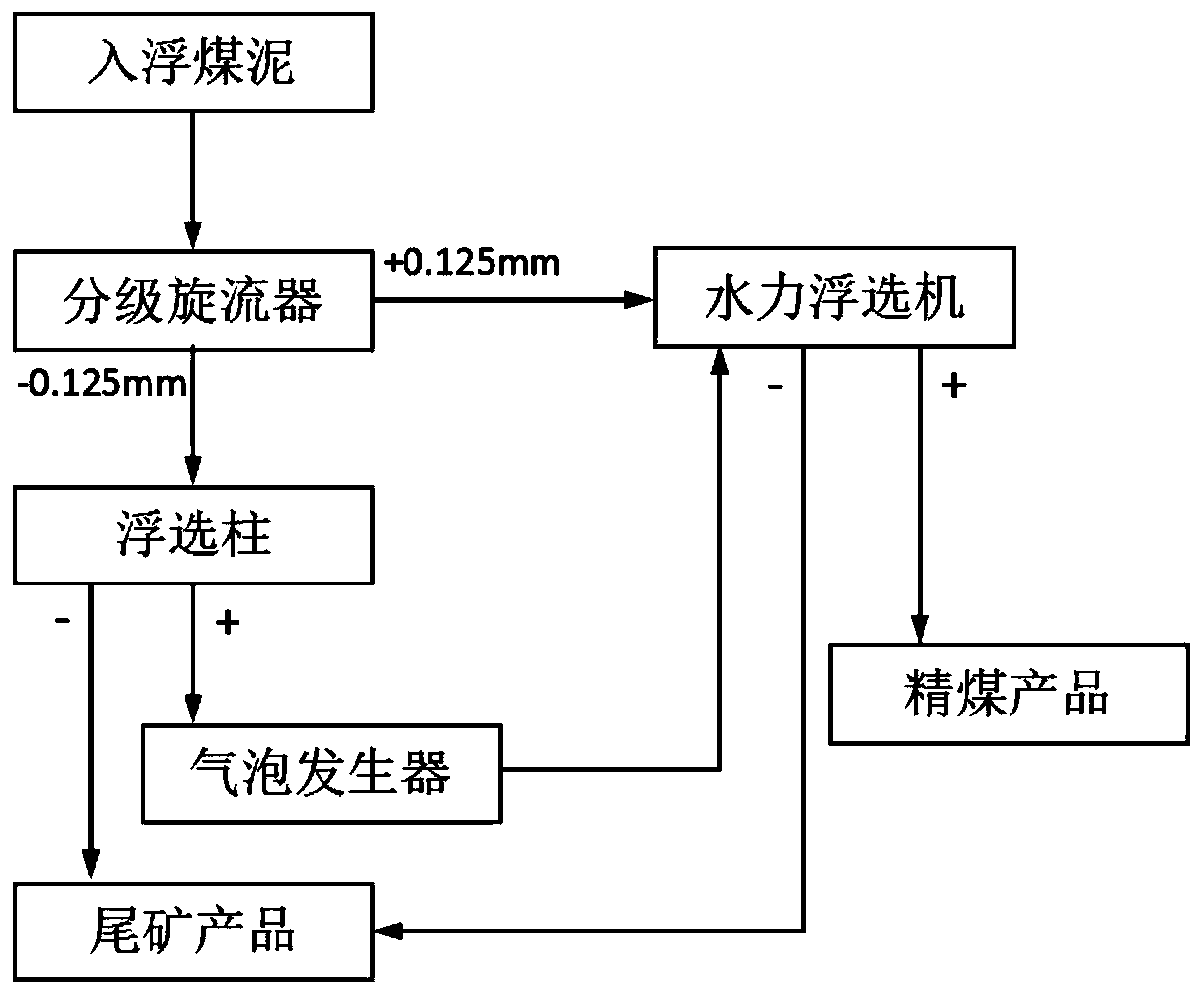

[0031] A specific embodiment of the present invention, such as figure 1 As shown, a wide particle size flotation process is disclosed, including the following steps:

[0032] Step 1: Feed the coal slime to be floated into the agitator 1, add water into the agitator 1 to mix the floating coal slurry, and then feed it into the classifying cyclone 2 via the first feed pump a for pre-classification; Ground, the floating coal slime is classified according to 0.125mm in the classification cyclone 2, that is, the classification accuracy of the classification cyclone 2 is ±0.125mm, the particle size in the overflow of the classification cyclone is -0.125mm, and the particle size in the underflow It is ﹢0.125mm.

[0033] Step 2: After the classification of coal slime in the classification cyclone 2 is completed, the overflow in the classification cyclone 2 is supplied to the flotation column 4 by the second feed pump b for flotation. After the flotation is completed, the flotation tailings...

Embodiment 2

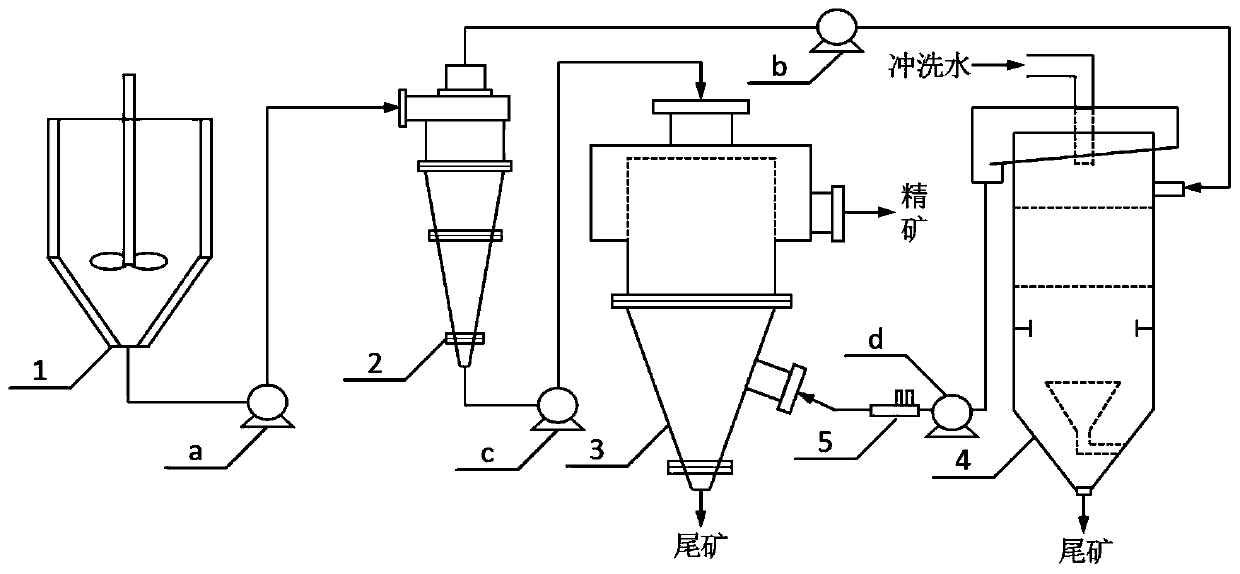

[0039] A specific embodiment of the present invention, such as figure 2 As shown, the wide-grain flotation system used in the wide-grain flotation process in the first embodiment is disclosed. A stirrer 1, a grading cyclone 2 and a flotation device are arranged along the separation pipeline. Stirrer 1 There is a first feed pump a between the grading cyclone 2 and the flotation device includes a hydraulic flotation machine 3 and a flotation column 4; the top of the grading cyclone 2 is provided with an upper discharge port and an upper discharge port Connected to the flotation column 4, a second feed pump b is provided between the upper discharge port and the flotation column 4; the bottom of the grading cyclone 2 is provided with a lower discharge port, which is connected to the hydraulic flotation machine 3 connection, a third feed pump c is provided between the lower discharge port and the hydraulic flotation machine 3. The flotation column 4 is provided with an underflow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com