Shoe tree 3D printing manufacturing method

A technology of 3D printing and manufacturing method, which is applied in the field of shoe last manufacturing technology, can solve the problems of large waste of materials, long production cycle, difficult modification, etc., and achieves the effects of high product quality, reduced work intensity, and easy modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

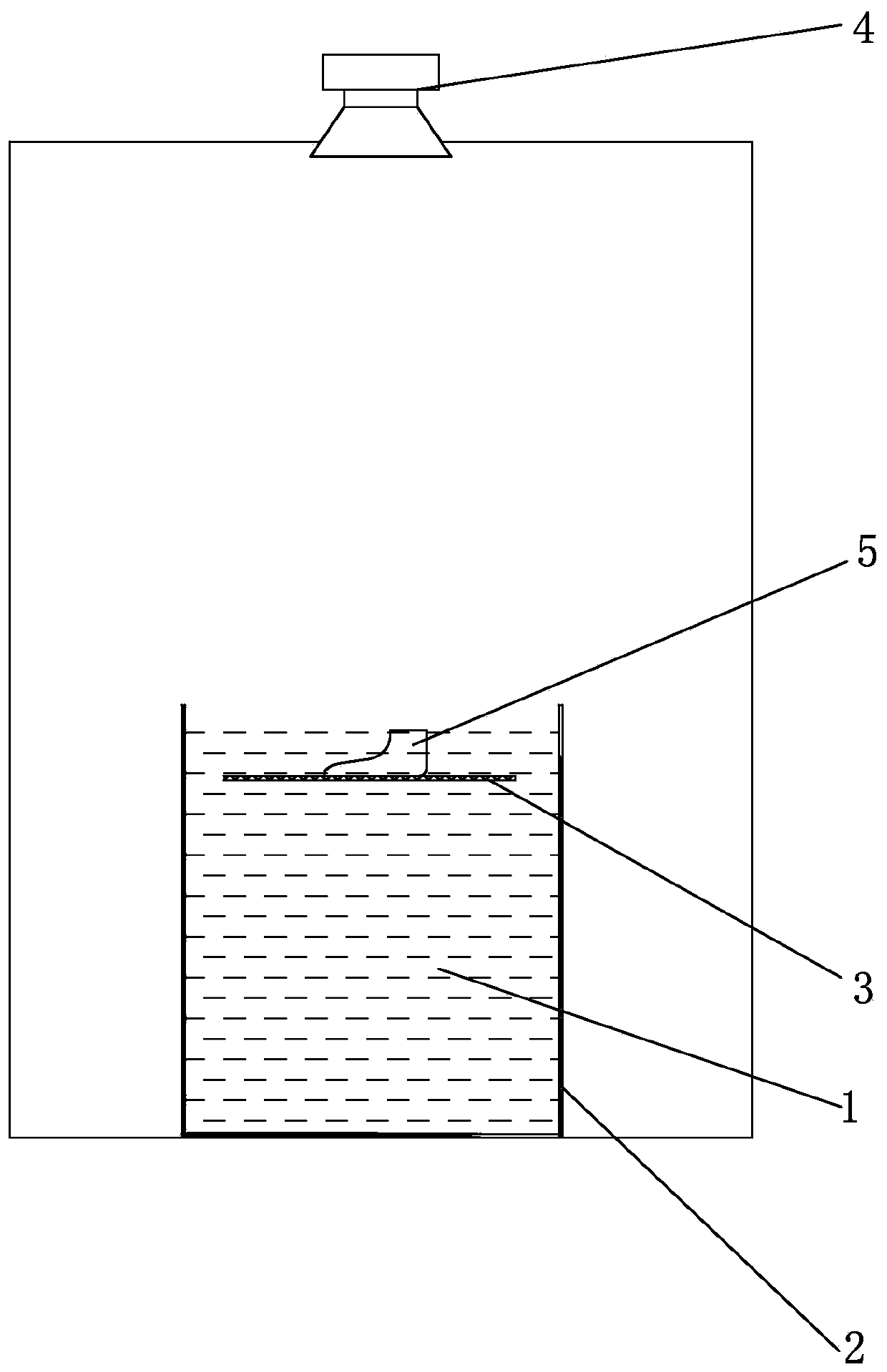

[0014] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0015] The invention is a 3D printing manufacturing method of a shoe last, the method comprising the following steps:

[0016] The first step is to make computer drawings of shoe lasts as needed. The design files of the shoe last can be different drawing software such as AUTOCAD, SOLIDWORK, UG, PROE, etc. These files can be easily converted into the common STL file format of the 3D printing system.

[0017] The second step is to input the data information of the drawn computer drawings into the 3D printer for 3D printing of the shoe last. The SLA printing technology adopted in the present invention, for example, selects a high-speed printing SLA equipment (model FORCE-P-6045) with a variable spot digital galvanometer. The cured light spot can be changed according to the precision requirement, and the laser scanning speed of the printing equipment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com