Process for treating alkaline malachite green production wastewater

A technology for wastewater treatment and wastewater treatment agent, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc. It can solve the problem of low efficiency of alkaline green wastewater treatment and achieve reactive Strong, good use effect, good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of wastewater treatment process for production of alkaline green, comprising the following steps:

[0029] S0, pretreatment: filter the alkaline magenta wastewater to be treated to remove impurities in the wastewater;

[0030] S1, adding an acid-base regulator to the pretreated alkaline magenta wastewater to adjust the pH of the wastewater to 5.5-6;

[0031] S2. After dissolving chlorin with ethanol, add it to an aqueous solution of poloxamer with a mass concentration of 10%, add chitosan, and stir to obtain a waste water treatment agent for future use, wherein chlorin and polox The molar ratio of chitosan to poloxamer is 1:5, and the molar ratio of chitosan to poloxamer is 1:1;

[0032] S3. Adding a wastewater treatment agent to the pH-adjusted wastewater and stirring for 20 minutes, wherein the amount of the wastewater treatment agent added accounts for 0.5% of the wastewater quality;

[0033] S4, placing the stirred wastewater under an ultraviolet lamp with ...

Embodiment 2

[0036] A kind of wastewater treatment process for production of alkaline green, comprising the following steps:

[0037] S0, pretreatment: filter the alkaline magenta wastewater to be treated to remove impurities in the wastewater;

[0038] S1, adding an acid-base regulator to the pretreated alkaline magenta wastewater to adjust the pH of the wastewater to 5.5-6;

[0039] S2. After dissolving chlorin with ethanol, add it to an aqueous solution of poloxamer with a mass concentration of 10%, add chitosan, and stir to obtain a waste water treatment agent for future use, wherein chlorin and polox The molar ratio of chitosan to poloxamer is 1:7, and the molar ratio of chitosan to poloxamer is 1:2;

[0040] S3. Adding a wastewater treatment agent to the pH-adjusted wastewater and stirring for 20 minutes, wherein the amount of the wastewater treatment agent added accounts for 0.7% of the wastewater quality;

[0041] S4, placing the stirred wastewater under an ultraviolet lamp with ...

Embodiment 3

[0044] A kind of wastewater treatment process for production of alkaline green, comprising the following steps:

[0045] S0, pretreatment: filter the alkaline magenta wastewater to be treated to remove impurities in the wastewater;

[0046] S1, adding an acid-base regulator to the pretreated alkaline magenta wastewater to adjust the pH of the wastewater to 5.5-6;

[0047] S2. After dissolving chlorin with ethanol, add it to an aqueous solution of poloxamer with a mass concentration of 10%, add chitosan, and stir to obtain a waste water treatment agent for future use, wherein chlorin and polox The molar ratio of chitosan to poloxamer is 1:12, and the molar ratio of chitosan to poloxamer is 1:3;

[0048] S3. Add wastewater treatment agent to the wastewater after pH adjustment, and stir for 35 minutes, wherein the amount of wastewater treatment agent added accounts for 1% of the wastewater quality;

[0049] S4, placing the stirred wastewater under an ultraviolet lamp with a wav...

PUM

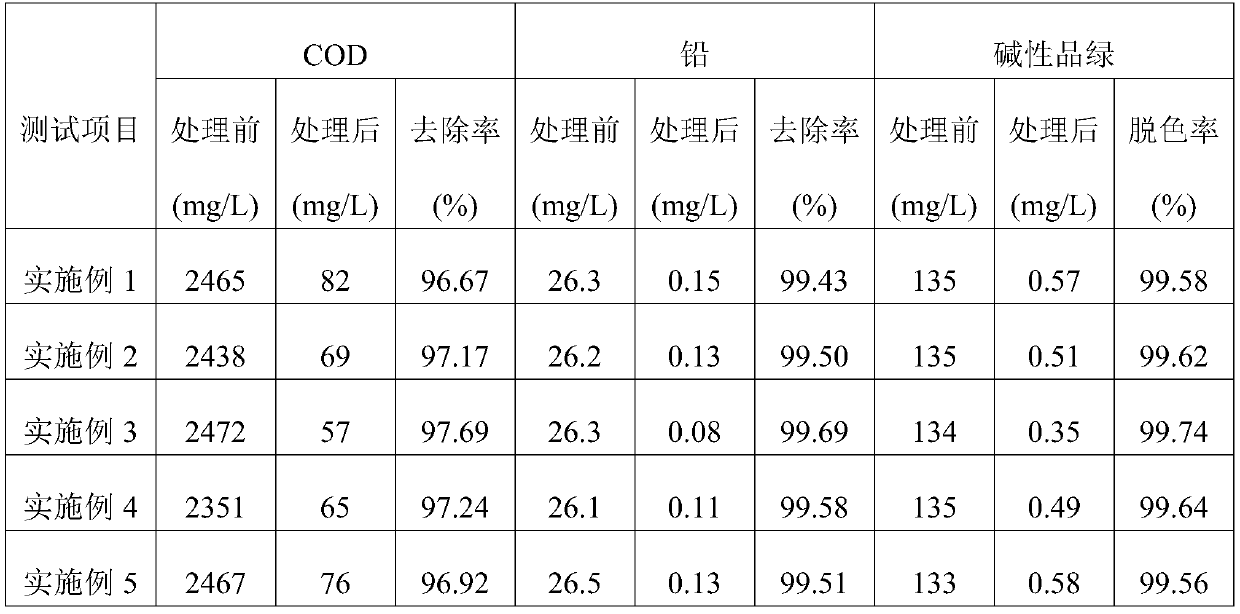

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com